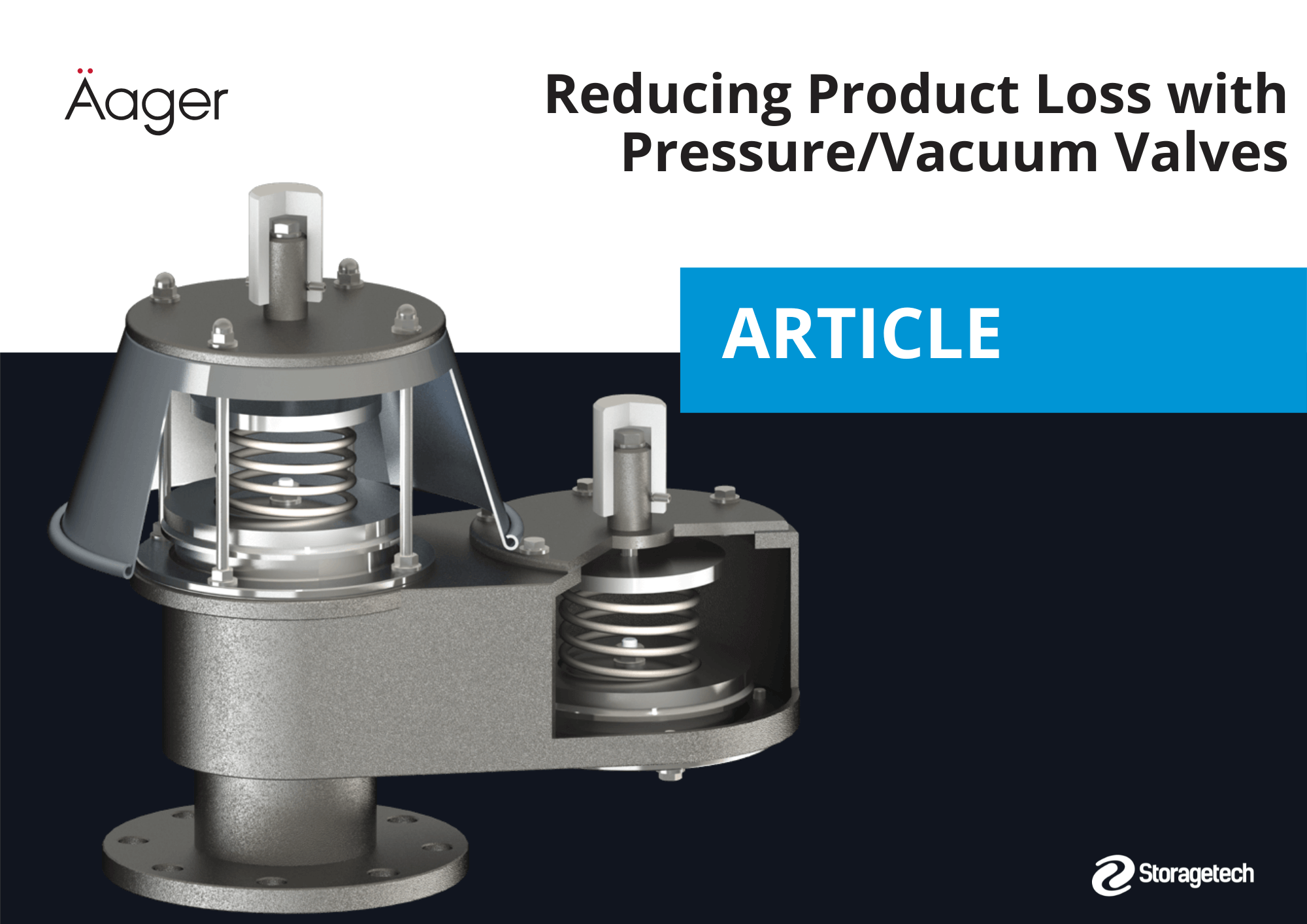

Introduction: Why “Pressure Vacuum Valves 2025” Matter

As industries enter a new era of stricter safety regulations and sustainability goals, Pressure Vacuum Valves 2025 are becoming critical components in storage and processing facilities worldwide. These valves protect tanks from structural damage caused by overpressure or vacuum conditions, while also reducing vapor emissions. The innovations expected in 2025 reflect advances in material science, digital monitoring, and regulatory requirements — making P/V valves smarter, safer, and more efficient than ever.

Pressure Vacuum Valves 2025

Global Market Trends and Outlook

The global market for pressure vacuum valves is expanding rapidly. In 2024, the industry size was estimated at USD 1.5 billion, and projections indicate steady growth through 2033 with a CAGR of nearly 7–8%. This expansion is driven by:

-

Rising demand for safe storage in oil & gas, petrochemicals, and chemicals.

-

Tighter environmental laws requiring reduced fugitive vapor emissions.

-

Increased adoption of biofuels and renewable energy storage, where safety and compliance are essential.

Against this backdrop, Pressure Vacuum Valves 2025 are positioned as the standard solution for future-ready tank venting systems.

Innovations in Pressure Vacuum Valves 2025

-

Smart Monitoring & IoT Integration

Modern P/V valves are increasingly equipped with sensors and remote monitoring features. Facilities can now track real-time tank pressure data, receive alerts, and schedule predictive maintenance. -

Enhanced Sealing Performance

Advanced sealing technologies and precision machining reduce leakage rates, ensuring compliance with strict emissions standards and minimizing product losses. -

High-Performance Materials

Corrosion-resistant alloys, composite coatings, and engineered elastomers provide durability against aggressive chemicals, extreme temperatures, and harsh weather. -

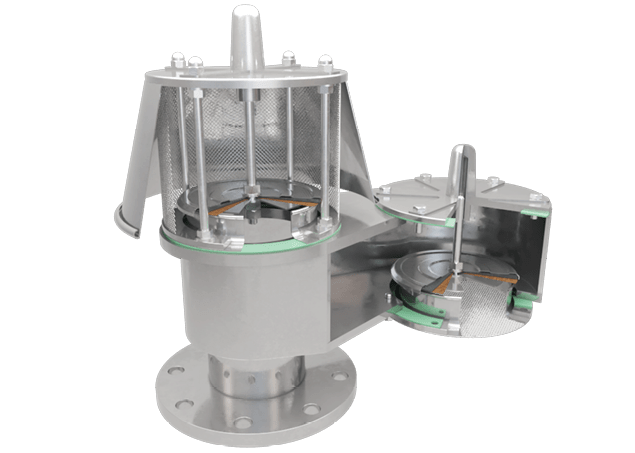

Flame Arrestor Integration

To improve safety in flammable environments, new designs combine flame arrestors with pressure vacuum valves, preventing external ignition sources from reaching the vapor space. -

Modular & Easy-Maintenance Designs

Test-in-place kits, modular construction, and tool-free access are emerging trends, enabling operators to service valves without lengthy downtime.

Types of Pressure Vacuum Valves 2025

-

Spring-Loaded Valves – Adjustable and versatile, widely used where flexibility in setpoints is required.

-

Weight-Loaded Valves – Simple, stable, and reliable for predictable pressure control.

-

Conservation (Tight-Seal) Valves – Designed to minimize vapor loss during normal tank “breathing.”

-

Flame-Arrestor Integrated Valves – Provide dual protection: pressure/vacuum relief and flame arresting.

-

Top-Mount, Mid-Mount, and In-Line Variants – Different mounting options ensure compatibility with various tank configurations.

Each type serves specific industry needs, and selecting the right one depends on tank capacity, vapor properties, and compliance requirements.

Key Selection Criteria

When specifying Pressure Vacuum Valves 2025, consider the following:

-

Set Pressure & Vacuum Range – Must align with the tank’s design pressure limits.

-

Leakage Performance – Ultra-low leakage valves help reduce emissions.

-

Relieving Capacity – Sufficient to handle surges during filling or thermal expansion.

-

Material Compatibility – Stainless steel, aluminum, or special alloys for chemical resistance.

-

Certifications – Compliance with API, ATEX, PED, CE, and local safety standards.

-

Testing & Maintenance Access – Built-in test ports and modular designs ease routine inspections.

-

Smart Features – Sensors, data logging, and connectivity options for digital facilities.

Applications Across Industries

Pressure Vacuum Valves 2025 are essential in:

-

Oil & gas storage terminals

-

Petrochemical and chemical plants

-

Aviation fuel and marine fuel storage

-

Biofuel and ethanol blending facilities

-

Wastewater and vapor recovery systems

-

Marine cargo tanks and offshore operations

In every sector, these valves ensure regulatory compliance, reduce emissions, and safeguard valuable infrastructure.

Pressure Vacuum Valves 2025

Installation and Maintenance Best Practices

-

Correct Orientation – Install vertically and ensure alignment with manufacturer instructions.

-

Regular Inspections – Semiannual or annual checks for set pressure accuracy and sealing integrity.

-

Cleaning and Debris Control – Keep vent paths clear to prevent blockage.

-

Calibration – Verify pressure and vacuum settings periodically to maintain safety.

-

Seal and Gasket Replacement – Replace elastomeric parts as part of preventive maintenance.

-

Documentation – Maintain detailed service logs for audits and compliance reporting.

-

Spare Parts Management – Keep essential components in stock to minimize downtime.

Future Trends for Pressure Vacuum Valves 2025 and Beyond

As industries evolve, so do the demands on safety equipment. Pressure Vacuum Valves 2025 are no longer just mechanical devices; they are transforming into smart, adaptive systems. Key trends expected to shape the future include:

-

Digital Twin Integration – Engineers can now model valve performance digitally before installation, predicting behavior under different conditions.

-

AI-Driven Maintenance – Artificial intelligence will analyze valve data, predicting when service is required, reducing costly downtime.

-

Sustainability Focus – With global decarbonization efforts, valves are being designed to minimize environmental impact, including carbon-neutral materials and recyclable components.

-

Global Harmonization of Standards – Regulators worldwide are aligning safety and emissions standards, making it easier for companies to standardize equipment across regions.

Environmental Impact of Pressure Vacuum Valves 2025

Environmental protection is at the core of next-generation tank venting solutions. By preventing excess vapor loss, these valves directly reduce volatile organic compound (VOC) emissions. Benefits include:

-

Compliance with stricter 2025 emission limits set by agencies like the EPA and European Environmental Directives.

-

Reduction in greenhouse gas emissions from fuel and chemical storage facilities.

-

Improved workplace safety by limiting exposure to hazardous vapors.

The adoption of Pressure Vacuum Valves 2025 supports companies’ Environmental, Social, and Governance (ESG) commitments, aligning with global sustainability goals.

Comparing Traditional vs. Pressure Vacuum Valves 2025

| Feature | Traditional P/V Valves | Pressure Vacuum Valves 2025 |

|---|---|---|

| Monitoring | Manual checks only | IoT sensors & remote monitoring |

| Emission Control | Basic sealing | Ultra-low leakage, conservation designs |

| Maintenance | Frequent disassembly | Modular, test-in-place kits |

| Materials | Standard alloys | High-performance, corrosion-resistant |

| Compliance | Regional standards | Global certifications (API, ATEX, CE, PED) |

This comparison highlights why upgrading to Pressure Vacuum Valves 2025 is not just an option, but a necessity for forward-thinking industries.

Case Study: Implementing Pressure Vacuum Valves 2025 in Fuel Terminals

A major European fuel terminal recently upgraded its tank farm with next-generation Pressure Vacuum Valves 2025. Results included:

-

40% reduction in fugitive emissions measured over 12 months.

-

30% lower maintenance costs due to modular designs and predictive monitoring.

-

Compliance with ISO 28300 / API 2000 venting standards, avoiding costly penalties.

-

Improved community relations by reducing odor complaints from nearby residential areas.

This real-world case demonstrates the operational and financial benefits of adopting advanced P/V technology.

Best Practices for Selecting the Right Pressure Vacuum Valves 2025 Supplier

Choosing the right valve is important — but so is choosing the right partner. When evaluating suppliers in 2025, consider:

-

Proven Track Record – Look for companies with extensive experience in tank venting solutions.

-

Customization Options – Every facility is unique; valves should be tailored to specific requirements.

-

Technical Support & Training – Access to engineers, documentation, and training ensures long-term reliability.

-

Global Certifications – Ensure products are certified for your operational region.

-

After-Sales Service – Reliable spare parts and responsive maintenance support reduce downtime.

Pressure Vacuum Valves 2025

Conclusion: The Future is Pressure Vacuum Valves 2025

The transition to Pressure Vacuum Valves 2025 represents more than a product upgrade — it’s an investment in safety, efficiency, and sustainability. With smart technology, advanced sealing, and global compliance, these valves are setting the benchmark for modern tank venting systems.

Organizations that adopt them now will not only meet today’s regulations but also be prepared for the stricter requirements of tomorrow.

At StorageTech, we are committed to engineering the future of pressure vacuum solutions. Contact our experts today to explore how our Pressure Vacuum Valves 2025 can transform your operations.