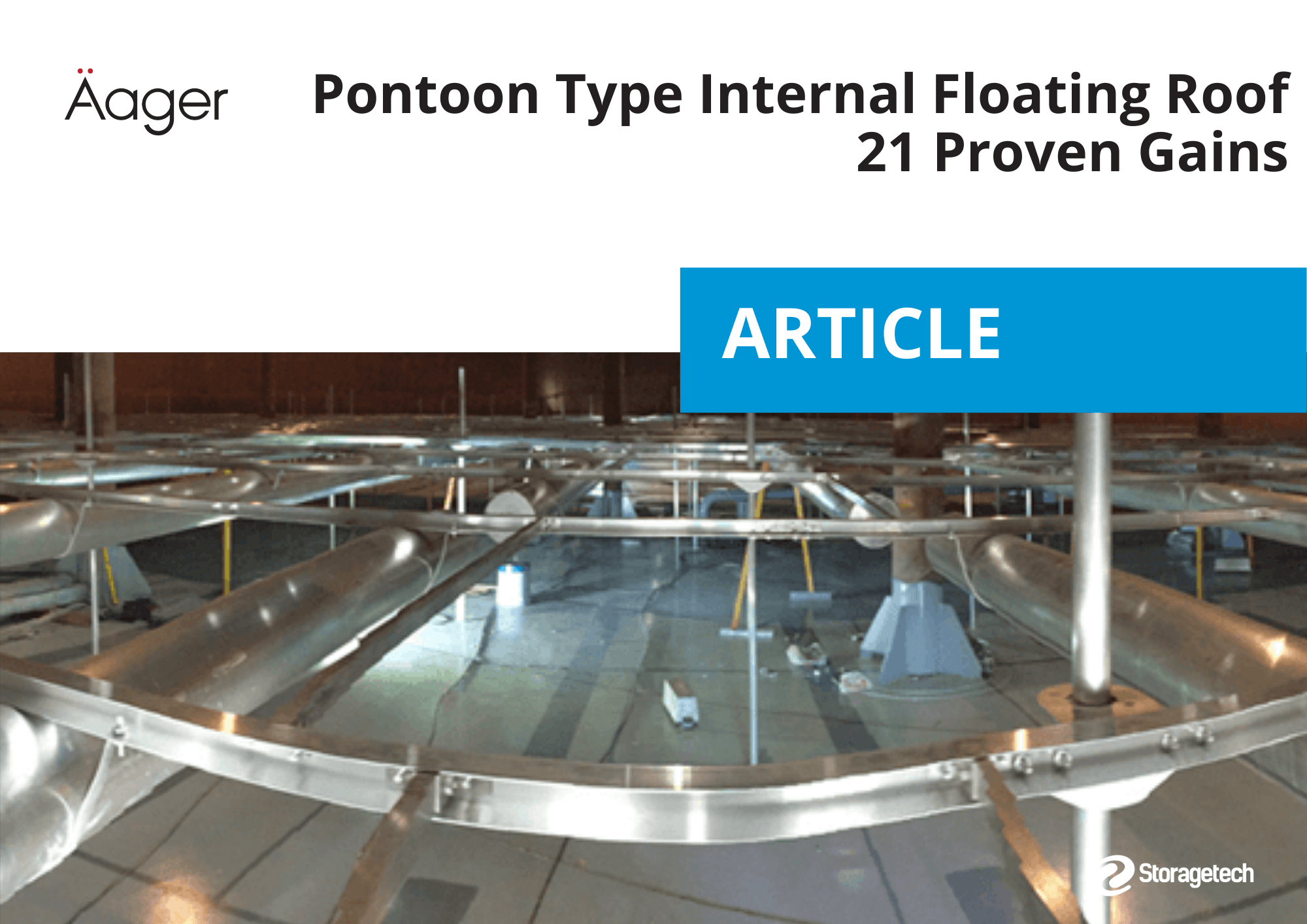

A Pontoon Type Internal Floating Roof is a proven solution for reducing evaporation losses in fixed-roof atmospheric storage tanks. It does this by floating on the product surface and limiting vapor space, while its rim seals restrict vapor movement at the tank wall. The concept is straightforward, but the real-world performance depends on details: tank geometry, pontoon layout, seal selection, fittings, and installation quality.

If you’re looking for a “nuts and bolts” guide, you’re in the right place. This article explains what a Pontoon Type Internal Floating Roof is, how it works, how to select it, and how to keep it reliable for years. It is written in clear English, with practical engineering logic you can use in specifications, technical clarifications, and site execution.

You’ll also see why a Pontoon Type Internal Floating Roof can be a no-drama choice for many services—provided you respect a few key rules. When teams skip those rules, roofs bind, seals fail early, and performance drops. The goal here is simple: help you get predictable results.

1. Fundamentals of Pontoon Type Internal Floating Roof

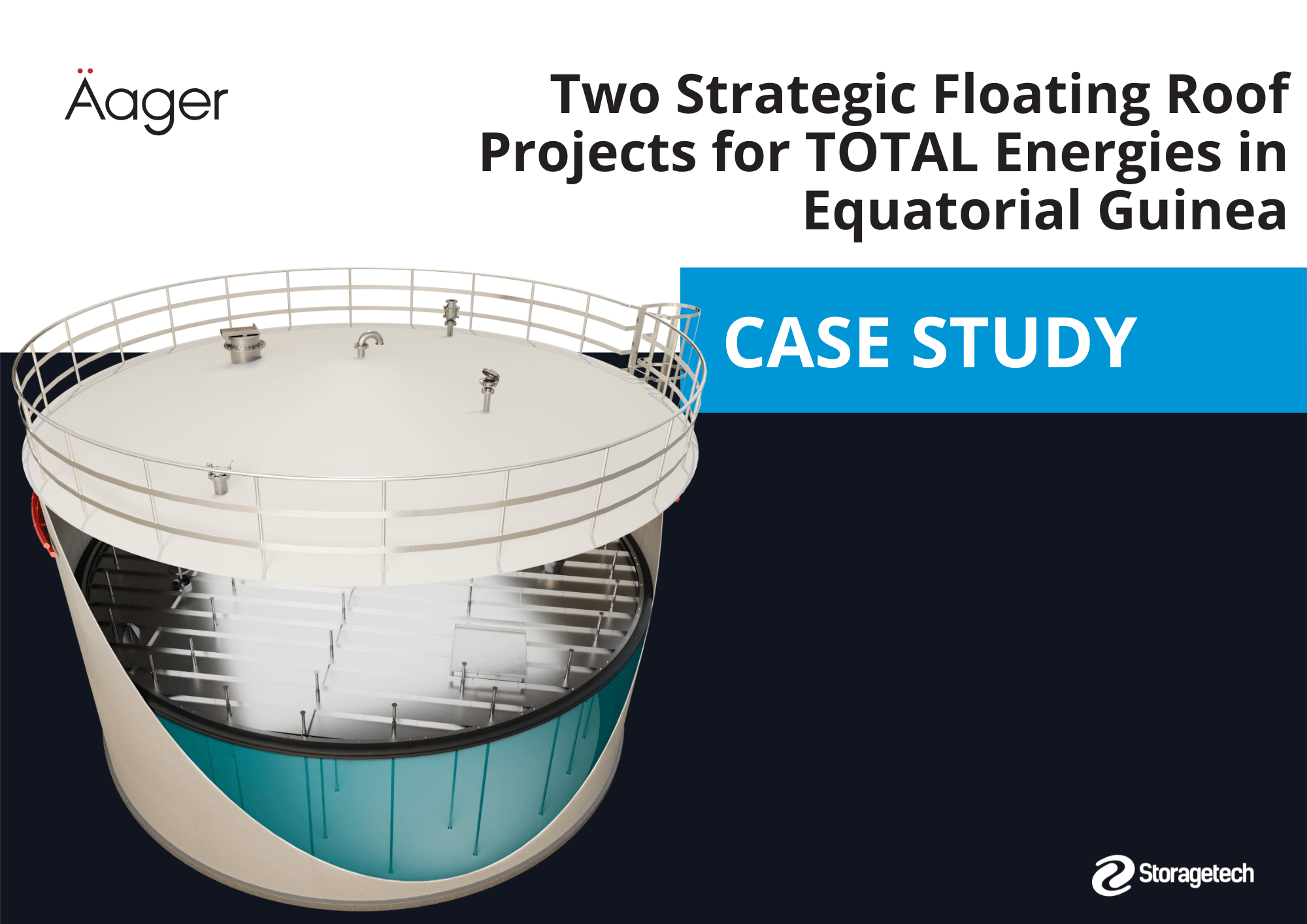

A Pontoon Type Internal Floating Roof is installed inside a fixed-roof tank. It sits on the liquid surface and rises and falls as the tank level changes. The term “pontoon type” means buoyancy is provided mainly by sealed pontoon compartments, commonly arranged around the perimeter and sometimes supported with additional internal pontoons.

This design is popular because it balances performance and robustness. A Pontoon Type Internal Floating Roof can be lightweight, stable, and relatively tolerant of normal operating conditions, especially when compared with designs that rely on full-surface contact.

How the pontoon deck floats

Buoyancy is the whole game. A Pontoon Type Internal Floating Roof uses enclosed air spaces (pontoons) to create an upward force that supports the deck and accessories. When product level changes, the roof moves with it.

In practical terms, good pontoon design focuses on:

-

Buoyancy margin: Enough flotation capacity to support the roof even with reasonable loads (like liquid splash, residues, or minor product on the deck surface due to operational events).

-

Stability: Resistance to tilt. A stable Pontoon Type Internal Floating Roof should not “wobble” or bind when it travels.

-

Compartment integrity: Sealed pontoons should stay sealed. Leaks reduce buoyancy and can cause uneven flotation.

A helpful way to think about it: the Pontoon Type Internal Floating Roof is like a wide raft with a tight edge seal. The raft must stay level, and the seal must stay engaged.

Core components (what you’re really buying)

A complete Pontoon Type Internal Floating Roof package typically includes more than the deck. In real projects, performance is driven by the full system:

1) Pontoon deck assembly

-

Perimeter pontoons (often segmented compartments)

-

Deck skin and structural members

-

Anti-rotation devices (as required)

2) Support system

-

Deck legs for low-level support (adjustable heights)

-

Leg sleeves and wear pads (where needed)

-

Landing pads or shoes (project-dependent)

3) Rim seal system

-

Primary seal (main barrier)

-

Secondary seal (backup barrier, often required for stronger control)

4) Penetrations and fittings

-

Gauge pole well or stilling well (if required)

-

Sample wells, access hatches, bleeder vents

-

Vacuum breakers or vents (depending on design philosophy)

5) Hardware and accessories

-

Fasteners, clips, flexible connectors

-

Bonding/grounding provisions (per project rules)

-

Compatibility items (gaskets, wipers, sleeves)

If you only compare deck weights or material grade, you’ll miss the point. The best Pontoon Type Internal Floating Roof results come from a balanced package: robust pontoons, reliable rim seals, and well-controlled fittings.

Typical applications (where pontoon type shines)

A Pontoon Type Internal Floating Roof is commonly applied in:

-

Terminals storing refined fuels and blend components

-

Chemical tanks with vapor loss concerns

-

Large atmospheric tanks where stability is critical

-

Facilities aiming to reduce VOC emissions and product loss

It is often a strong fit when:

-

You have normal product cleanliness (no heavy sludge layers)

-

Tank cycling is moderate to high (frequent level changes)

-

You want robust buoyancy and stable travel behavior

-

You need a practical design that maintenance teams can inspect

A Pontoon Type Internal Floating Roof may require special consideration when:

-

Product forms wax, polymer, or heavy solids on the surface

-

Internal tank obstructions are complex (many columns or piping)

-

Tank shell roundness is poor (seal performance becomes difficult)

When pontoon is a strong choice (selection cues)

Use these practical cues to decide if a Pontoon Type Internal Floating Roof is a good candidate:

-

You need stability: Pontoon buoyancy supports a level, steady deck.

-

You want maintainability: Many pontoon designs are modular and inspectable.

-

You have a fixed roof tank: The Pontoon Type Internal Floating Roof is built for that environment.

-

You want a balanced approach: Strong performance without overly delicate mechanics.

In short, a Pontoon Type Internal Floating Roof is often a dependable middle path: solid performance with fewer “gotchas,” as long as the seals and fittings are done correctly.

2. Seals, Fittings, and Performance

If you want results you can defend, focus here. A Pontoon Type Internal Floating Roof reduces vapor losses by limiting vapor space and sealing the rim gap. In many tanks, the rim gap and fittings dominate losses. That’s why seals and penetrations are not “minor details.” They are the business end of the system.

Rim seal architecture (primary and secondary seals)

A Pontoon Type Internal Floating Roof typically uses rim seals to minimize vapor flow between the deck edge and the tank shell. The seal must maintain contact across level changes, minor tank irregularities, and thermal movement.

Primary seal

-

The main sealing element

-

Handles most of the vapor control

-

Must be product-compatible and mechanically stable

Secondary seal

-

Adds an extra barrier and reduces leakage risk

-

Often improves long-term performance, especially as the primary seal ages

-

Can also help with tolerance to shell out-of-roundness

Key performance drivers for seals on a Pontoon Type Internal Floating Roof:

-

Correct compression/contact pressure (not too tight, not too loose)

-

Compatibility with stored product and vapors

-

Resistance to hardening, cracking, swelling, and wear

-

Proper installation and alignment around the full circumference

A simple truth: you can buy a premium deck and still get mediocre performance if the seal system is weak. A Pontoon Type Internal Floating Roof is only as good as its rim sealing strategy.

Fitting losses and how to control them

Fittings are often the hidden source of vapor losses. Every penetration—gauge poles, hatches, vents—can leak if it’s not designed and maintained properly.

Common fittings on a Pontoon Type Internal Floating Roof include:

-

Gauge pole well / stilling well

-

Deck access hatches

-

Bleeder vents (to release trapped vapors during filling/emptying)

-

Leg sleeves and guides

-

Column sleeves (if internal columns exist)

Good practice for controlling fitting losses:

-

Specify tight-fitting wipers and sealing elements for moving interfaces

-

Use proven designs for gauge wells and access points

-

Avoid unnecessary penetrations (each one is a risk point)

-

Define test and inspection expectations for critical fittings

If your project has strict emissions targets, treat fittings like you’d treat flange joints on a vapor line: defined design, traceable installation, and planned inspection.

Emissions and product loss drivers (what really changes performance)

A Pontoon Type Internal Floating Roof typically improves performance through three mechanisms:

-

Reduced vapor space

-

Less volume for vapor accumulation

-

Less breathing-driven loss during temperature changes

-

Reduced liquid surface exposure

-

Lower evaporation potential when vapor circulation is limited

-

Restricted rim flow

-

Rim seals reduce the main “leak path” around the deck edge

However, performance can degrade when:

-

Rim seals lose contact or wear unevenly

-

The roof binds due to misalignment or tank geometry issues

-

Fittings leak (often overlooked during inspections)

-

Pontoons lose integrity and buoyancy becomes uneven

A practical recommendation: when evaluating a Pontoon Type Internal Floating Roof, ask for the vendor’s approach to seal design, fitting controls, and tolerance to shell roundness. Those items predict performance more reliably than marketing claims.

Safety considerations (what you must not ignore)

A Pontoon Type Internal Floating Roof influences tank safety, but it does not replace the need for proper tank safety systems. It can reduce vapor accumulation under typical conditions, yet it introduces interfaces and movement that must be managed.

Key safety topics include:

Static electricity

-

Filling and flow can generate static

-

Bonding/grounding provisions and anti-static measures are commonly required

-

Operational discipline matters (don’t skip procedures)

Venting behavior

-

Vapors can be trapped under the deck

-

Proper bleeder venting supports controlled filling/emptying

-

Poor venting can lead to unexpected pressure pockets

Mechanical integrity

-

Deck legs must land evenly

-

Binding and rubbing can damage seals and create debris

-

A stable Pontoon Type Internal Floating Roof reduces abnormal contact forces

Inspection checkpoints (fast, practical checks)

When inspectors look at a Pontoon Type Internal Floating Roof, the best checks are often the simplest:

-

Rim seals: Look for tears, gaps, hardening, uneven wear, or loose hardware.

-

Deck level: Signs of tilt can point to buoyancy issues or binding.

-

Pontoons: Evidence of dents, corrosion, or leak paths should be investigated.

-

Fittings: Confirm gauge wells and vents are intact and properly sealed.

-

Travel behavior: If the roof doesn’t move freely, performance and safety both suffer.

If you can see obvious gaps at the rim, vapors can move there too. It’s not a lab test, but it’s a reliable early warning sign.

For broader context on storage tank emissions and why vapor controls matter, the U.S. EPA provides practical background information here:

3. Selection, Installation, and Lifecycle Value

A Pontoon Type Internal Floating Roof will usually perform well when the selection is fit-for-service, the installation is controlled, and maintenance is planned. Most failures come from predictable misses: unclear specifications, poor tank geometry checks, or “we’ll fix it later” execution.

Specification checklist (what to define in the RFQ)

If you want comparable bids and fewer clarifications, define these items up front for the Pontoon Type Internal Floating Roof:

Tank and geometry

-

Tank diameter and height

-

Roof type and internal obstructions (columns, piping, nozzles)

-

Shell roundness data (if available) and tolerance expectations

-

Internal coating system (if any)

Service and operating profile

-

Stored product and key properties (including volatility)

-

Normal operating temperature range

-

Fill/empty frequency and level range

-

Presence of mixing, recirculation, or agitation

Design requirements

-

Pontoon arrangement expectations (perimeter-only vs added internal support)

-

Minimum buoyancy margin and compartment integrity expectations

-

Primary and secondary seal requirement (and material constraints)

-

Fitting list and tightness expectations

-

Bonding/grounding requirements (per site rules)

Quality and documentation

-

Material certificates (as required)

-

Inspection and test plan expectations

-

As-built documentation deliverables

-

Recommended spares for the Pontoon Type Internal Floating Roof

When you specify clearly, suppliers can engineer properly. When you don’t, you’ll get “apples to oranges” offers and risk a roof that looks fine on paper but struggles in the tank.

Installation best practices (where projects often win or lose)

A Pontoon Type Internal Floating Roof installation should be treated like a precision assembly, not a rough fit-up. It’s not fragile, but it does require discipline.

Best practices include:

1) Pre-install checks

-

Verify tank internal cleanliness (debris ruins seals)

-

Confirm tank roundness and identify tight spots

-

Check internal obstructions and clearances

2) Controlled assembly

-

Use proper alignment tools and sequence

-

Protect seal materials during handling

-

Confirm pontoon compartment integrity (as specified)

3) Functional checks

-

Confirm free movement through expected level range

-

Verify leg landing heights and uniformity

-

Confirm vents and gauge wells are correctly installed

4) Documentation

-

Record key tolerances and as-built conditions

-

Track critical fastener torques where required

-

Capture final inspection photos for future reference

A practical tip: if the deck rubs during commissioning, it won’t magically improve. Investigate immediately. Binding is the fast track to seal wear and performance loss on a Pontoon Type Internal Floating Roof.

Maintenance strategy (keep it performing, year after year)

A Pontoon Type Internal Floating Roof is not a “lifetime no-maintenance” item. Seals wear. Fittings age. Hardware loosens over cycles. The good news is that a planned approach is straightforward.

A sensible maintenance plan typically includes:

-

Routine external monitoring of tank behavior (loss indicators, odor, abnormal venting)

-

Periodic internal inspection based on site strategy

-

Seal inspection and planned replacement intervals (service-dependent)

-

Fitting inspections (especially gauge wells and moving interfaces)

-

Spare parts management for critical seal components

Common issues and what they usually mean:

-

Uneven seal wear: tank out-of-roundness, misalignment, or binding.

-

Deck tilt: pontoon leak, uneven loads, or mechanical interference.

-

Frequent fitting leaks: poor installation control or inadequate sealing design.

With a disciplined program, a Pontoon Type Internal Floating Roof can deliver consistent performance across many operating cycles.

Cost and ROI thinking (where payback comes from)

The value case for a Pontoon Type Internal Floating Roof usually combines:

-

Reduced product loss (often the biggest measurable driver)

-

Reduced emissions burden and improved environmental posture (project-dependent)

-

Improved operational confidence and fewer vapor-related complaints

-

Potentially improved product quality for sensitive storage (service-dependent)

A practical ROI approach:

-

Estimate annual product loss reduction (based on volatility and operating profile).

-

Estimate annual maintenance cost (seals, inspections, spares).

-

Compare to capital cost and downtime risk.

In many storage applications, a Pontoon Type Internal Floating Roof is justified not only on compliance goals, but also on operational efficiency. When tanks cycle frequently, the savings can be meaningful.

FAQs

1) What makes a Pontoon Type Internal Floating Roof different from other internal floating roofs?

A Pontoon Type Internal Floating Roof relies mainly on sealed pontoon compartments for buoyancy. This often improves stability and can offer a robust design for many services.

2) Is a Pontoon Type Internal Floating Roof better than a full-contact design?

It depends on service and priorities. A Pontoon Type Internal Floating Roof often excels in stability and ruggedness. Full-contact designs may offer stronger vapor control in some cases, but can be more sensitive to surface contamination and operating conditions.

3) Do I always need primary and secondary seals?

Not always, but many projects specify both. For a Pontoon Type Internal Floating Roof, adding a secondary seal can improve long-term tightness and reduce performance drop as the primary seal ages.

4) What are the biggest causes of poor performance?

Most issues come from seal problems, fitting leaks, tank roundness challenges, or binding. A Pontoon Type Internal Floating Roof performs best when tank geometry is checked and installation is controlled.

5) How often should seals be replaced?

There’s no single interval. It depends on product compatibility, cycling rate, temperature, and inspection results. For a Pontoon Type Internal Floating Roof, a planned inspection strategy with defined acceptance criteria is the safest approach.

6) What should I ask vendors during technical evaluation?

Ask about buoyancy margin, pontoon compartment integrity, seal design and materials, fitting tightness controls, tolerance to tank out-of-roundness, and recommended spares for the Pontoon Type Internal Floating Roof.

7) Where can I read a neutral reference about storage tank emissions?

The U.S. EPA resource on storage tanks is a helpful starting point for understanding emission drivers and control concepts:

Conclusion

A Pontoon Type Internal Floating Roof is a practical, widely adopted approach to reducing vapor losses and improving control inside fixed-roof tanks. Its strength is balance: stable buoyancy, straightforward mechanics, and a system architecture that can be maintained predictably.

To get the outcomes you want, treat the Pontoon Type Internal Floating Roof as an engineered system, not just a deck. Specify the seals and fittings clearly, verify tank geometry, install with discipline, and plan inspection and spares. Do that, and you’ll avoid the common headaches while capturing the real value—lower losses, improved operational confidence, and a stronger environmental posture.