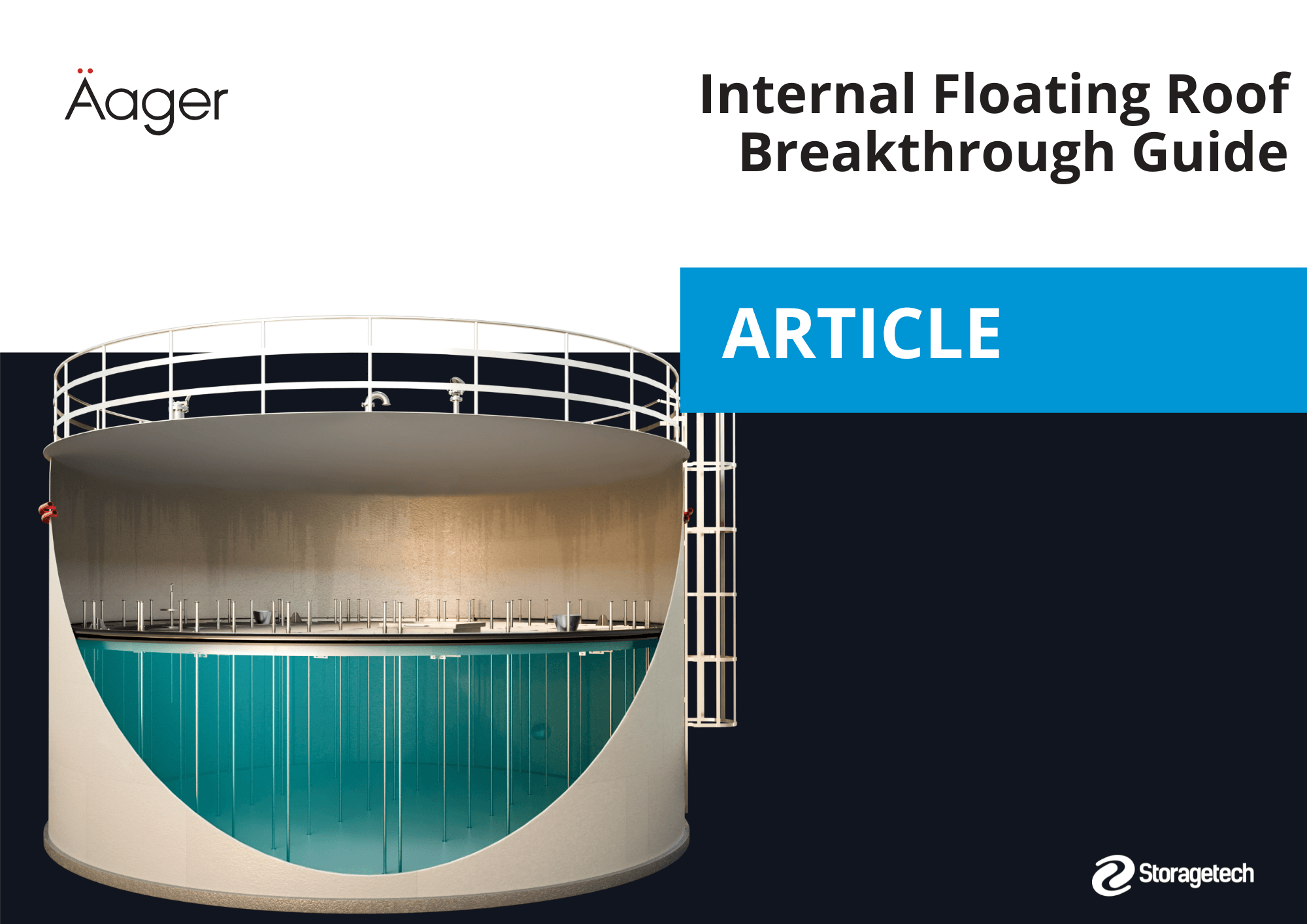

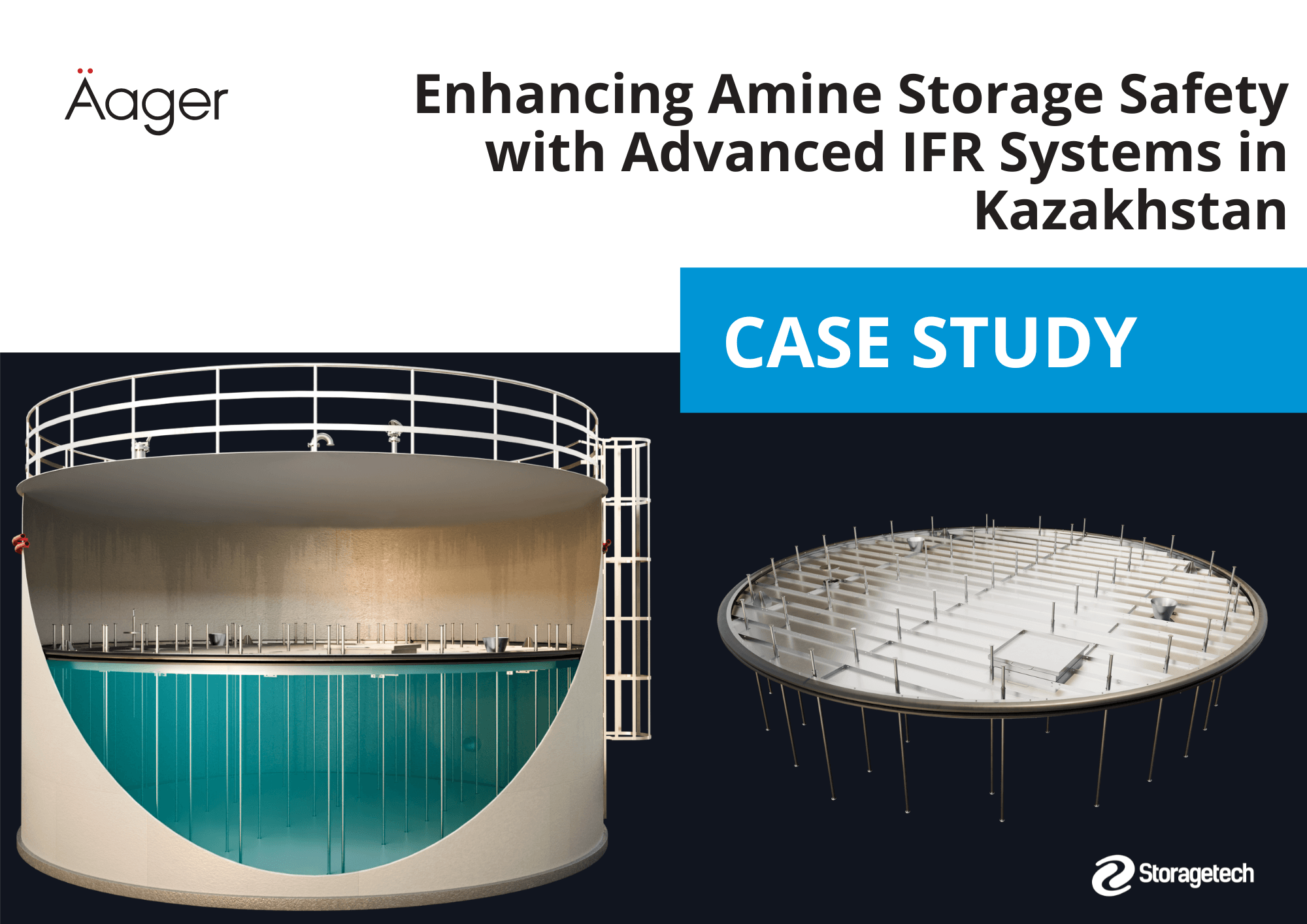

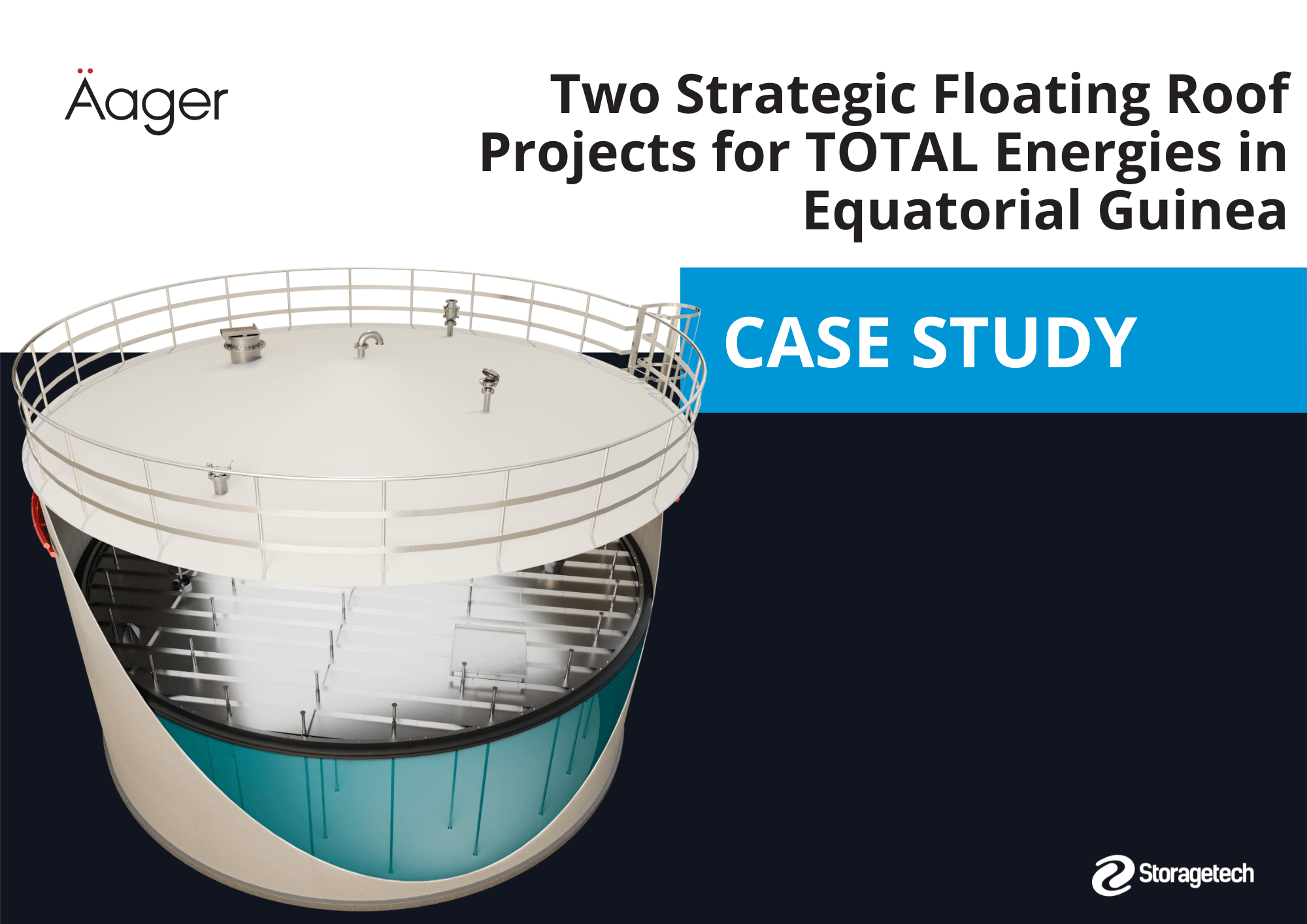

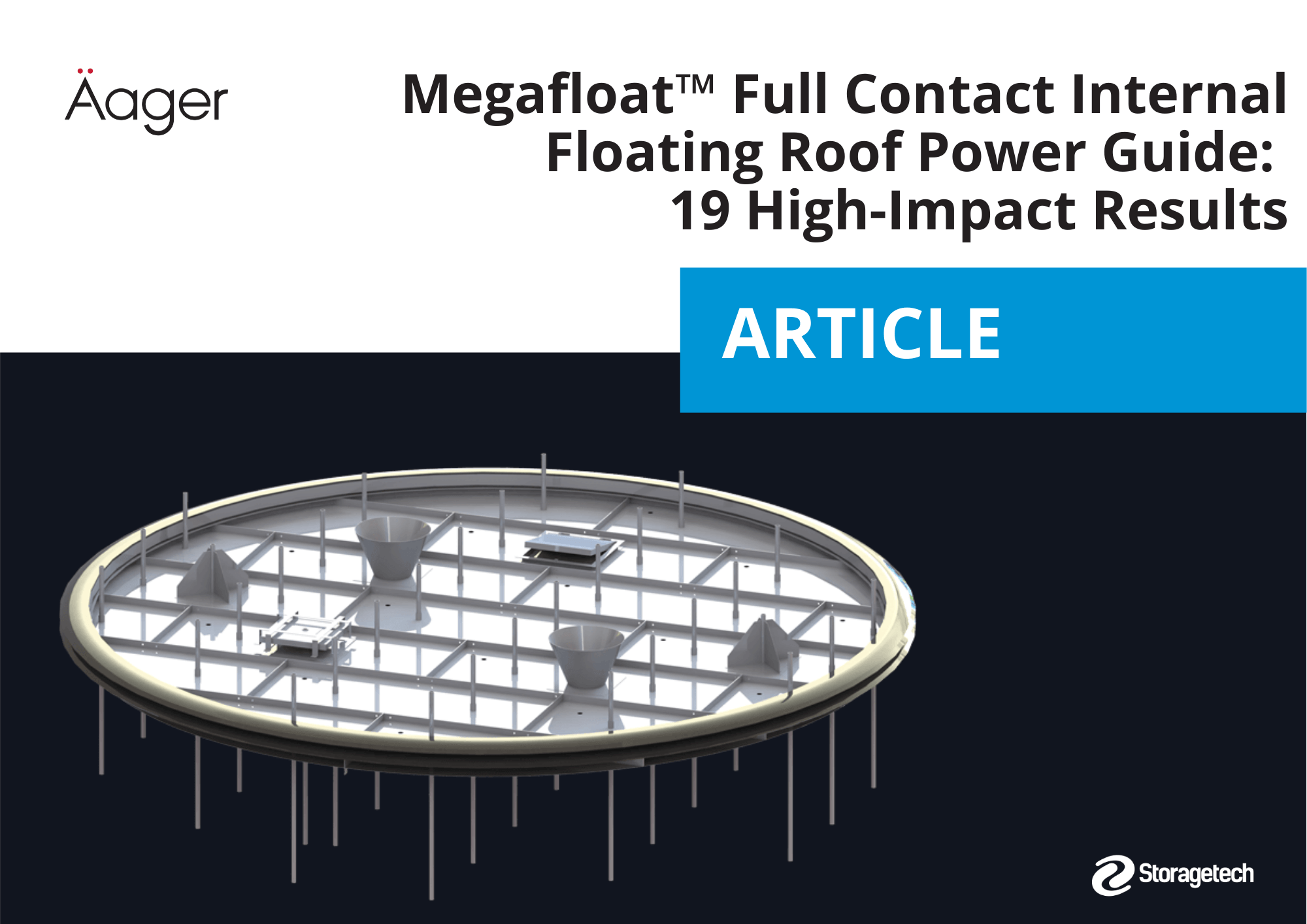

A Megafloat™ Full Contact Internal Floating Roof is designed to float directly on the liquid surface inside a fixed-roof storage tank, while keeping the deck in close contact with the product. The goal is straightforward: reduce the vapor space, reduce evaporation, and improve control of vapors that can otherwise build up under a fixed roof. When it’s specified correctly, a Megafloat™ Full Contact Internal Floating Roof can deliver measurable product-loss reduction and support emissions targets in a practical, scalable way.

That said, “full contact” isn’t magic. It’s a design approach with clear advantages and a few pitfalls. The upside is strong vapor control potential because there’s less vapor space and less exposed surface behavior. The downside is that the system can be less forgiving if the product creates sludge, wax, heavy residue, or debris that interferes with deck travel and seals. In other words, the devil is in the details.

This article is written as an engineering and operations guide. It explains how a Megafloat™ Full Contact Internal Floating Roof works, what components matter most, how seals and fittings affect real-world results, and what to put in your RFQ so you don’t end up comparing apples to oranges. It also includes an inspection and maintenance approach that keeps performance stable over years—not just on day one.

1. System Fundamentals and Architecture

A Megafloat™ Full Contact Internal Floating Roof is installed inside a fixed-roof tank and floats up and down with the stored liquid. Unlike some internal floating roof designs that have more vapor space under the deck or rely mainly on perimeter buoyancy, a “full contact” concept aims to keep the deck closely following the liquid surface. That helps reduce the vapor volume and can improve vapor-loss control when paired with a well-designed rim seal system.

What “full contact” really means

In practical terms, “full contact” means the deck is designed so the gap between the deck and the liquid surface is minimized during normal operation. Less gap generally means less vapor circulation and less evaporation opportunity. A Megafloat™ Full Contact Internal Floating Roof is therefore often selected when vapor-loss reduction is a high priority and the tank service is clean enough to support smooth roof travel.

However, full contact doesn’t mean “no movement issues ever.” You still need:

-

Adequate flotation margin to avoid tilt and binding

-

Controlled clearances at the rim and around internals

-

Seal materials that stay stable in the stored product

-

A clean tank environment so the deck does not ride up on debris

If the stored product forms heavy solids, sticky deposits, or thick surface layers, a Megafloat™ Full Contact Internal Floating Roof needs careful evaluation. Otherwise, you may face uneven travel, seal wear, and performance drop.

Deck construction and buoyancy logic

The roof’s deck is the platform. Its job is to float, stay level, and resist distortion. A Megafloat™ Full Contact Internal Floating Roof typically relies on engineered buoyancy features distributed to maintain stability across the deck area, not only at the edge. The intent is to maintain close surface following without losing levelness.

Key design ideas you should expect to see described in technical data:

-

Flotation margin: A reserve of buoyancy beyond the dry weight of the roof and accessories. This supports safe operation even with normal loads, splashing, or small liquid carryover events.

-

Uniform stiffness: Deck sections should resist sagging and oil-canning. Distortion can cause seal gaps.

-

Compartment integrity (where applicable): If buoyancy relies on compartments, those compartments must remain sealed and verifiable.

A simple way to judge whether the concept is credible: ask what happens if the tank sees a less-than-perfect day—minor debris, minor deposits, or a bit of liquid on the deck due to operating events. A good Megafloat™ Full Contact Internal Floating Roof design anticipates real operations.

Typical tank fit (where it belongs)

A Megafloat™ Full Contact Internal Floating Roof is primarily used in atmospheric fixed-roof tanks where emissions or product-loss reduction matters. It can be applied in:

-

Terminals and tank farms storing volatile or semi-volatile liquids

-

Chemical storage where vapor control is required

-

Facilities aiming to reduce odor and VOC release (project-dependent)

Tank fit depends on:

-

Tank diameter and roundness: Rim seal performance is sensitive to out-of-round shells.

-

Internal obstructions: Columns, piping, and nozzles require sleeves and controlled clearances.

-

Operating level range: The roof must travel freely between high operating levels and low landing levels.

If a tank has many internal columns, you can still use a Megafloat™ Full Contact Internal Floating Roof, but you must treat column sleeves and clearances as a core design item, not a footnote.

Materials and compatibility

Material selection is not just about corrosion. It is also about weight and long-term stability. A Megafloat™ Full Contact Internal Floating Roof is often optimized for low weight, because lighter roofs are easier to float, easier to keep level, and easier on seals.

Typical material considerations include:

-

Aluminum structures for low weight and good general corrosion behavior in many tank environments

-

Stainless components where product or vapor space conditions demand it

-

Gaskets and polymer materials selected specifically for product compatibility

The most common avoidable mistake is selecting seal and gasket materials without considering the stored product’s chemistry, temperature range, and additives. A Megafloat™ Full Contact Internal Floating Roof can perform very well—until the wrong elastomer swells, shrinks, or hardens.

Common options you may specify

A complete Megafloat™ Full Contact Internal Floating Roof system typically includes options such as:

-

Adjustable deck legs for low-level support

-

Gauge pole well / stilling well (if required by operations)

-

Bleeder vents for controlled filling/emptying

-

Anti-rotation devices to prevent deck spinning

-

Access hatches for inspection and maintenance

-

Interfaces for internal columns (where present)

This is where you should be decisive in your RFQ. If you don’t define which fittings are required, you’ll get proposals that look comparable but behave very differently in service.

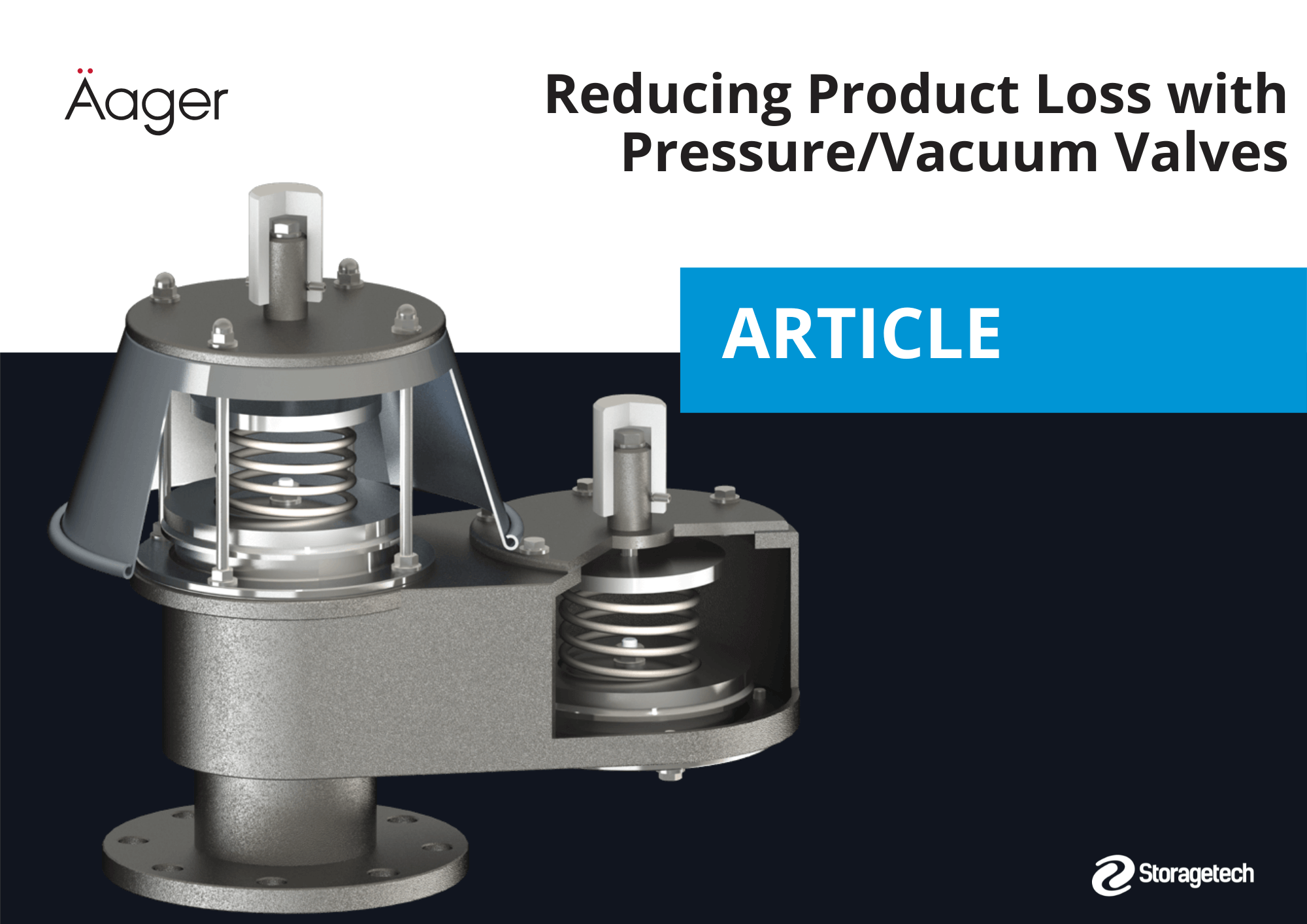

2. Sealing, Emissions Performance, and Safety

Most of the measurable value of a Megafloat™ Full Contact Internal Floating Roof is delivered by two things: rim sealing and fitting control. Full contact reduces vapor space, but rim gaps and penetrations can still leak a lot if they aren’t addressed with care. This section is where outcomes are won—or quietly lost.

Rim seal strategy (primary and secondary seals)

A Megafloat™ Full Contact Internal Floating Roof typically uses a rim seal system to restrict vapor movement between the deck perimeter and the tank shell.

You will commonly see:

-

Primary seal: The main barrier. It does the heavy lifting.

-

Secondary seal: A backup barrier to improve tightness and stability over time.

Seal performance depends on:

-

Consistent contact around the circumference

-

Correct compression (too tight causes wear; too loose causes leakage)

-

Compatibility with the stored liquid and vapor space

-

Mechanical design that tolerates shell irregularities

A practical truth: tanks are rarely perfectly round. A Megafloat™ Full Contact Internal Floating Roof seal strategy should be selected with the tank’s real geometry in mind, not the geometry in an ideal drawing.

Fittings and penetration controls

Every penetration is a potential leak point. In many real tanks, fitting losses rival rim losses if they’re not controlled.

Common penetrations on a Megafloat™ Full Contact Internal Floating Roof include:

-

Gauge pole wells / stilling wells

-

Deck access hatches

-

Bleeder vents

-

Leg sleeves and guides

-

Column sleeves (if internal columns exist)

Best practices for controlling fitting losses:

-

Specify sealing designs for moving interfaces (wipers, sleeves, guides)

-

Avoid unnecessary penetrations where possible

-

Require clear installation and inspection criteria for fittings

-

Plan spare sealing elements for the most active interfaces

If emissions performance is important, treat roof fittings like you would treat flanged joints on a vapor line: they need defined design intent and disciplined installation.

Performance drivers and failure modes

A Megafloat™ Full Contact Internal Floating Roof can deliver strong performance, but it is sensitive to a few predictable failure modes.

Key performance drivers:

-

Tight, stable rim seals

-

Controlled fittings

-

Free roof travel without binding

-

Clean tank environment and compatible materials

Common failure modes:

-

Seal degradation: wrong material, heat aging, swelling, cracking, or mechanical wear

-

Binding and rubbing: poor alignment, shell irregularity, interference with internals

-

Deck tilt: uneven buoyancy or uneven loading from deposits

-

Hidden fitting leaks: small gaps that grow over time

The best way to avoid surprises is to require a defined inspection approach and to document as-built conditions. A Megafloat™ Full Contact Internal Floating Roof that’s installed without verification tests is a gamble.

Static and bonding basics

Static electricity is not optional to discuss. A Megafloat™ Full Contact Internal Floating Roof sits in a flammable-vapor environment in many services. Practical controls usually include:

-

Bonding/grounding provisions (per site rules and applicable standards)

-

Operational procedures during filling and emptying

-

Avoiding practices that increase static risk (site-specific)

Your project’s governing standards and owner procedures should define what is mandatory. The key is that the roof design and installation must support those requirements.

Inspection checklist (fast, high-value checks)

For a Megafloat™ Full Contact Internal Floating Roof, a strong inspection routine often focuses on:

-

Rim seals: gaps, tears, hardening, uneven wear

-

Deck levelness: signs of tilt, distortion, or contact marks

-

Fittings: gauge wells, vents, hatches, sleeves—check sealing integrity

-

Travel behavior: the roof should move freely through the operating range

-

Hardware: loose fasteners, worn guides, damaged sleeves

A practical rule: if the rim seal shows daylight pathways or obvious gaps, vapors can move there too. It’s a simple observation, but it catches problems early.

For general background on storage tank emissions and control concepts, this external reference is a useful starting point:

3. Specification, Installation, and Lifecycle Value

A Megafloat™ Full Contact Internal Floating Roof typically delivers its best outcomes when you do three things well: write a clear specification, install with discipline, and maintain with a plan. None of these steps are complicated, but skipping them can turn a good design into a frustrating one.

RFQ/spec checklist (make bids comparable)

If you want clean, comparable offers for a Megafloat™ Full Contact Internal Floating Roof, define these items:

Tank data

-

Diameter, height, roof type

-

Internal obstructions (columns, piping, nozzles)

-

Shell roundness data (if available) and tolerance expectations

-

Coating system inside the tank (if any)

Service conditions

-

Stored product and known additives

-

Operating temperature range

-

Fill/empty frequency and typical level range

-

Presence of mixing or recirculation

Roof requirements

-

Confirmation of full-contact design intent and travel behavior

-

Flotation margin and stability expectations

-

Required primary and secondary rim seals

-

Fittings list (gauge well, vents, hatches, column sleeves, etc.)

-

Bonding/grounding provisions (per site requirements)

Quality and deliverables

-

Material certificates where required

-

Inspection and test plan (ITP) expectations

-

As-built documentation requirements

-

Recommended spares list for the Megafloat™ Full Contact Internal Floating Roof

The most expensive projects are often the ones with vague RFQs. Clear inputs reduce technical deviations and reduce risk.

Installation best practices (keep it smooth and predictable)

Installation quality is not a “nice to have.” A Megafloat™ Full Contact Internal Floating Roof relies on good fit and free movement.

High-value installation practices:

-

Verify tank cleanliness before installation (debris damages seals and guides)

-

Check internal clearances at columns and nozzles

-

Confirm rim seal contact and uniformity during assembly

-

Perform functional movement checks through the expected travel range

-

Verify landing behavior on deck legs at low levels

-

Confirm vents and gauge wells are installed and sealed correctly

-

Document key as-built measurements and observations

A practical tip: if the roof rubs during commissioning, it won’t get better with time. Find the interference and correct it early. Rubbing leads to seal wear, metal debris, and performance drop.

Maintenance and spares (what to plan for)

A Megafloat™ Full Contact Internal Floating Roof will not maintain peak performance without routine inspection and periodic parts replacement. That’s normal. Seals are wear items.

A sensible maintenance plan includes:

-

Periodic internal inspection aligned with site strategy

-

Rim seal condition checks and planned replacement criteria

-

Fitting inspections, especially moving interfaces (gauge wells, sleeves)

-

Hardware checks (fastener tightness, guide wear)

-

Documentation of findings and corrective actions

Typical spares to consider:

-

Primary and secondary seal materials or seal segments

-

Wipers/sleeves for gauge poles and columns

-

Fasteners and small hardware kits for critical fittings

-

Any special gasket materials specified for the roof package

If you manage spares proactively, repairs become planned maintenance instead of emergency downtime.

ROI and business case (why it’s often a no-brainer)

The business case for a Megafloat™ Full Contact Internal Floating Roof typically includes:

-

Reduced product evaporation losses (direct savings)

-

Improved emissions posture (project-dependent)

-

Reduced odor complaints and operational burden (site-dependent)

-

Better consistency in stored-product condition for sensitive services (where relevant)

A practical ROI framework:

-

Estimate product saved per year based on product volatility and cycling.

-

Estimate annual maintenance cost (seals, inspection labor, spares).

-

Compare with capital cost and downtime risk.

Many sites find that when tanks cycle frequently, the savings can justify the investment faster than expected. The key is stable performance, and stable performance comes from good seals, good installation, and a real maintenance plan.

FAQs

1) What is a Megafloat™ Full Contact Internal Floating Roof used for?

A Megafloat™ Full Contact Internal Floating Roof is used in fixed-roof tanks to reduce vapor space and evaporation losses, supporting product savings and emissions control goals.

2) Is full contact always better than pontoon type?

Not always. A Megafloat™ Full Contact Internal Floating Roof can offer strong vapor control, but it may be less tolerant of sludge, wax, or surface debris. Pontoon designs can be more forgiving in some services. Selection should match the product and operating profile.

3) What matters more: deck design or rim seals?

Rim seals and fitting controls often drive real-world results. A Megafloat™ Full Contact Internal Floating Roof benefits from reduced vapor space, but seal gaps and fitting leaks can still dominate losses if not controlled.

4) Do I need both primary and secondary seals?

Many projects specify both for stronger long-term tightness. For a Megafloat™ Full Contact Internal Floating Roof, a secondary seal can help maintain performance as the primary seal ages.

5) What are the most common problems in the field?

The common issues are seal wear, fitting leaks, deck rubbing/binding due to tank geometry, and tilt caused by uneven deposits or buoyancy issues. A disciplined installation and inspection plan reduces these risks.

6) What should I include in my RFQ to reduce deviations?

Include tank geometry and internals, stored product details, operating profile, required seals and fittings, bonding/grounding requirements, quality documentation, and an inspection/testing plan for the Megafloat™ Full Contact Internal Floating Roof.

7) Where can I read more about storage tank emissions in general?

The U.S. EPA provides helpful background on storage tanks and emissions concepts here:

Conclusion

A Megafloat™ Full Contact Internal Floating Roof can be a high-impact upgrade for fixed-roof tanks when vapor-loss reduction and emissions control are important. The strongest outcomes come from practical discipline: specify the roof and seals clearly, control penetrations, verify tank geometry, install carefully, and maintain seals as wear items. Do that, and you’ll get the predictable performance you’re aiming for—reduced losses, improved operational stability, and a stronger environmental posture.