Introduction:

Storagetech is a leading storage tank equipment manufacturer with more than 40 years of design

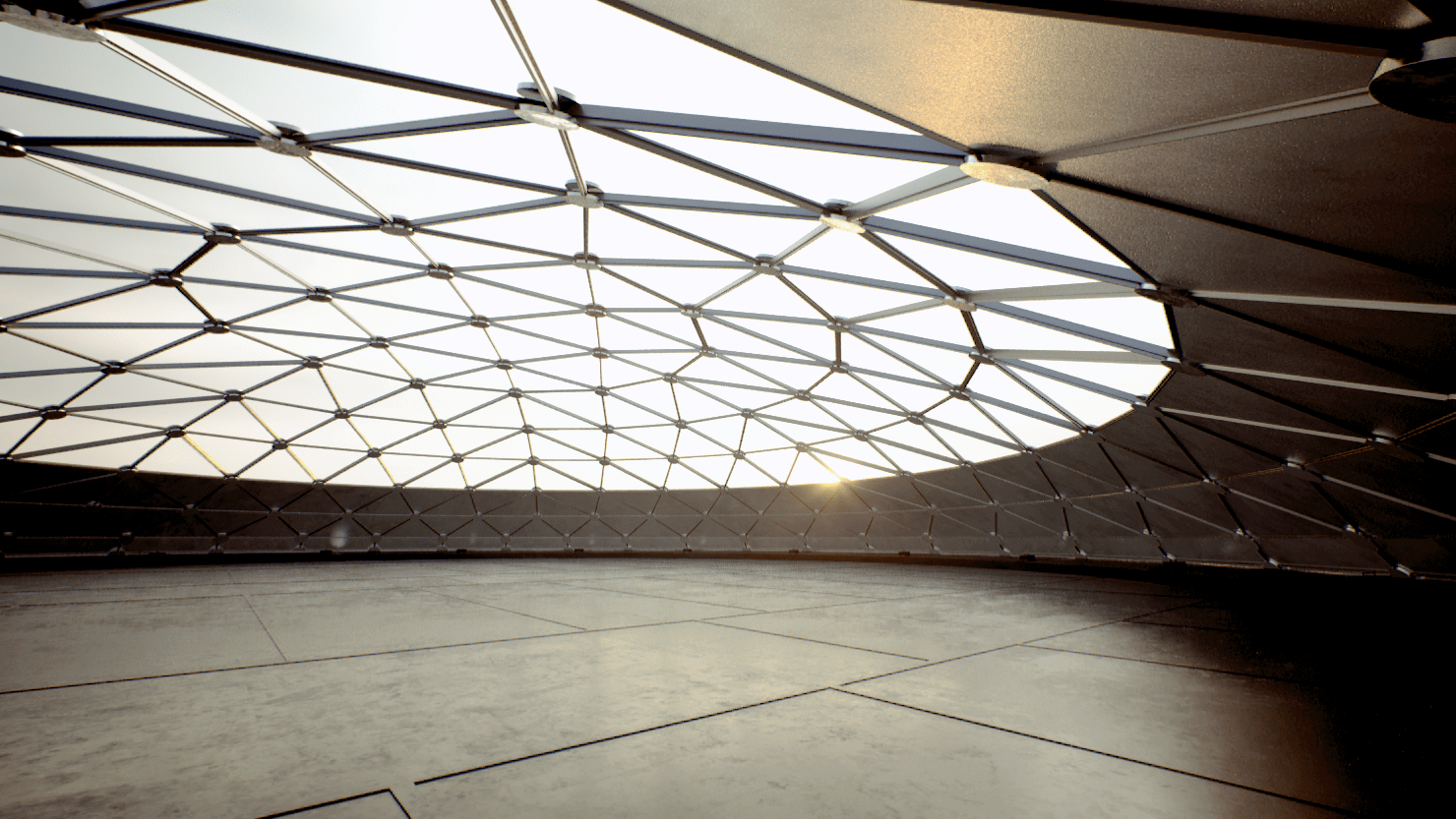

experience. Storagetech provides a total solution for storage tank emission control and roofing. Storagetech’s capabilities help customers to have the best solution from a single source. Storagetech provides Aluminum geodesic storage tank dome roofs for water, waste water, chemicals and hyrocarbons.

Aluminum geodesic dome roof is a kind of self supporting lightweight prefabricated structure that is used for storage tanks as an alternative to conventional carbon steel roofs. It basically consists of light weight profiles and triangle shape plates that can withstand very heavy loads for their size.

Each aluminum geodesic dome roof is designed as per customer specifications, local rules, regulations, environmental and storage tank conditions. We design our dome roofs as per the most common international design standards are API 650 Annex G, AWWA D108/ D103/D100 , ISO EN 1090, NFPA and ASCE 7.

What is an External Floating Roof (EFR)

EFR is a carbon steel roof consisting of pontoons that floats as per the liquid level on an open top storage tank.. It sits on mechanical legs at a certain height, which is usually above the manhole. Each EFS has a sealing system, which is mechanical or non-metallic, in order to minimize vapor losses.

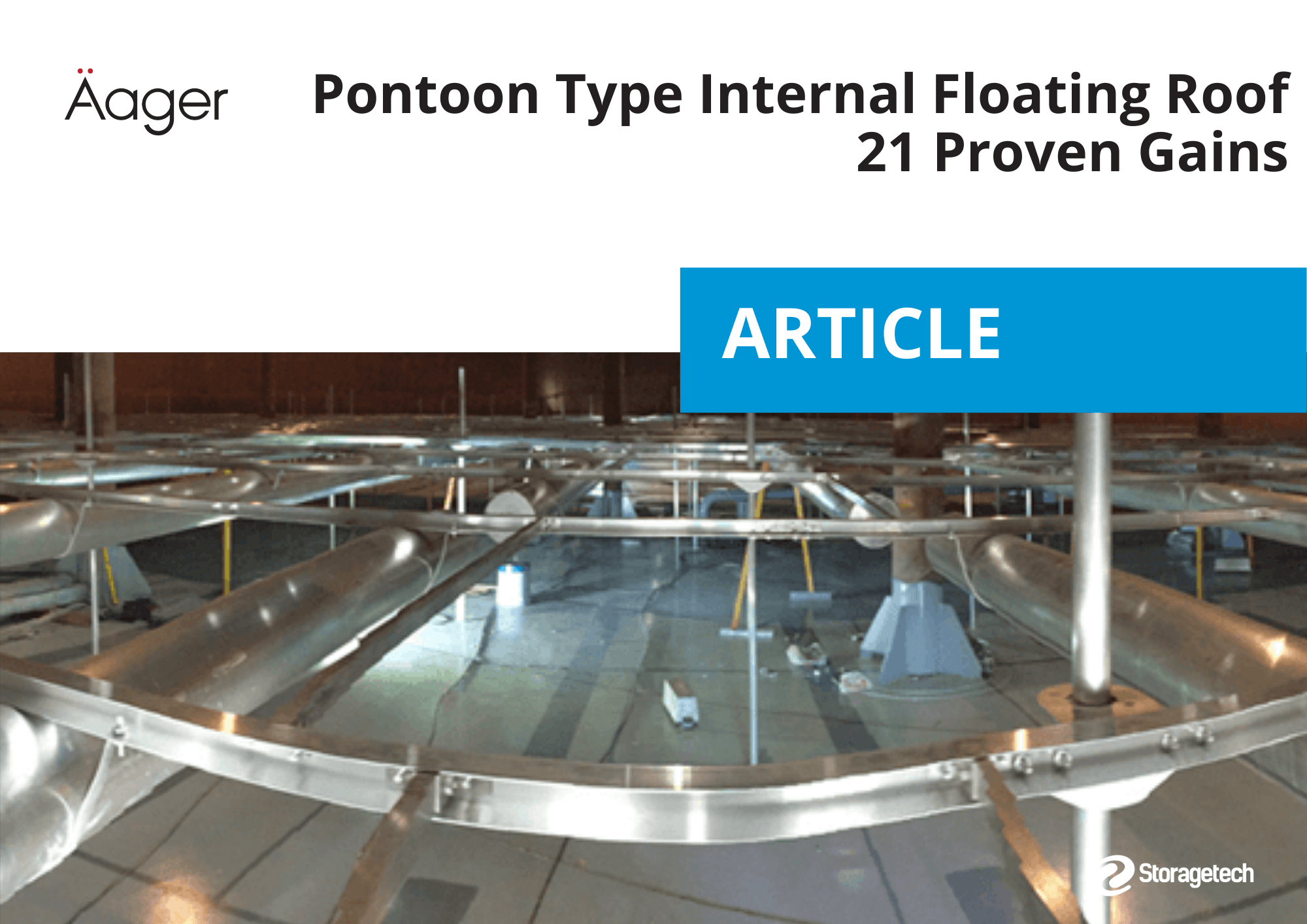

- Image 1: Single Deck Pontoon Type Floating Roof

- Image2: Double Deck Type Floating Roof[Bob. L & Bob. G, n.d, p.155]

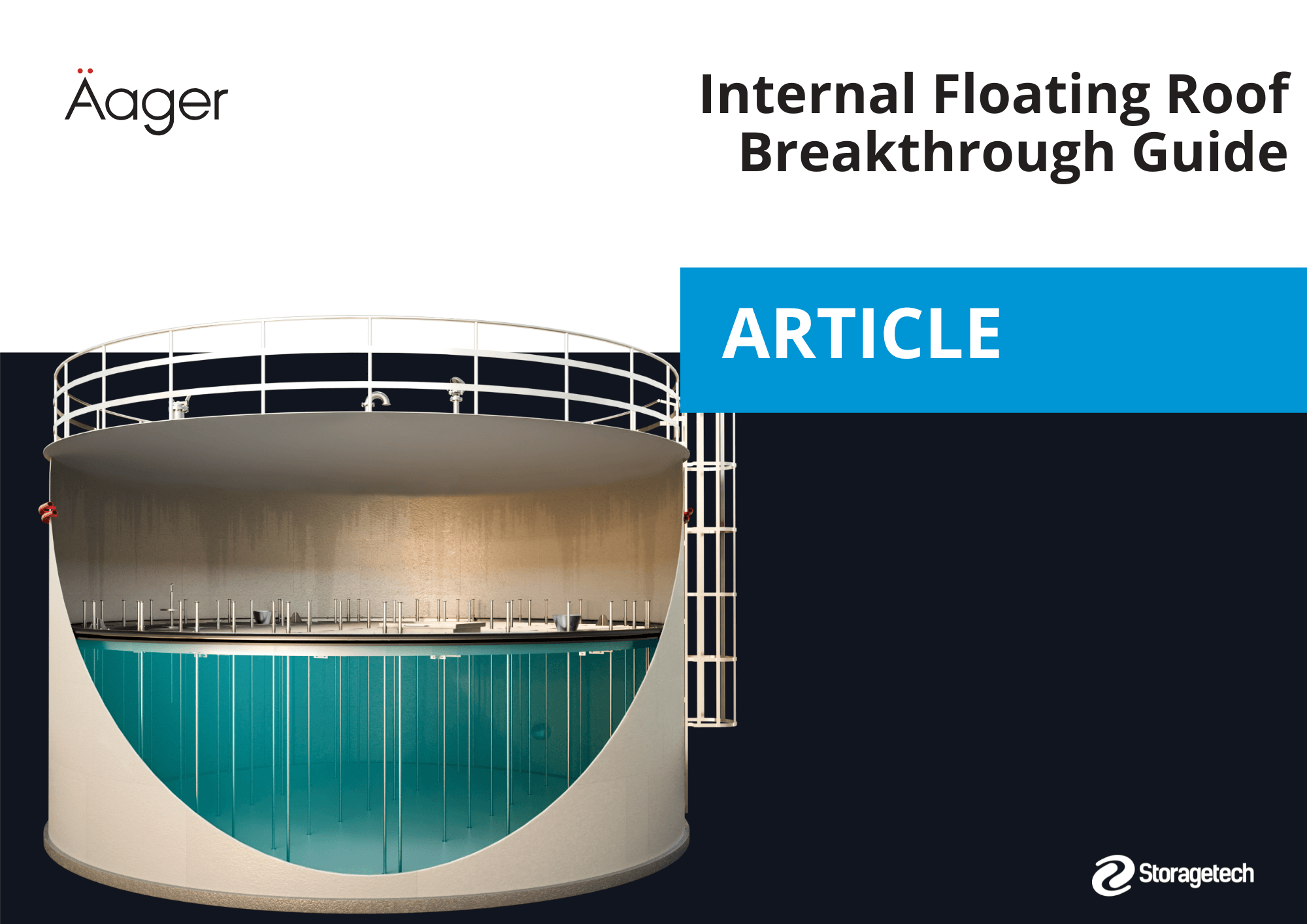

What is the difference between an internal and external floating roof?

The internal floating roof (IFR) storage tank has a type of fixed roof on top, whereas the external floating roof has an open top.The purpose of both types is the same: to reduce vapor losses, however the application area is usually different. Traditionally, EFR is preferred mostly with large crude oil storage tanks.

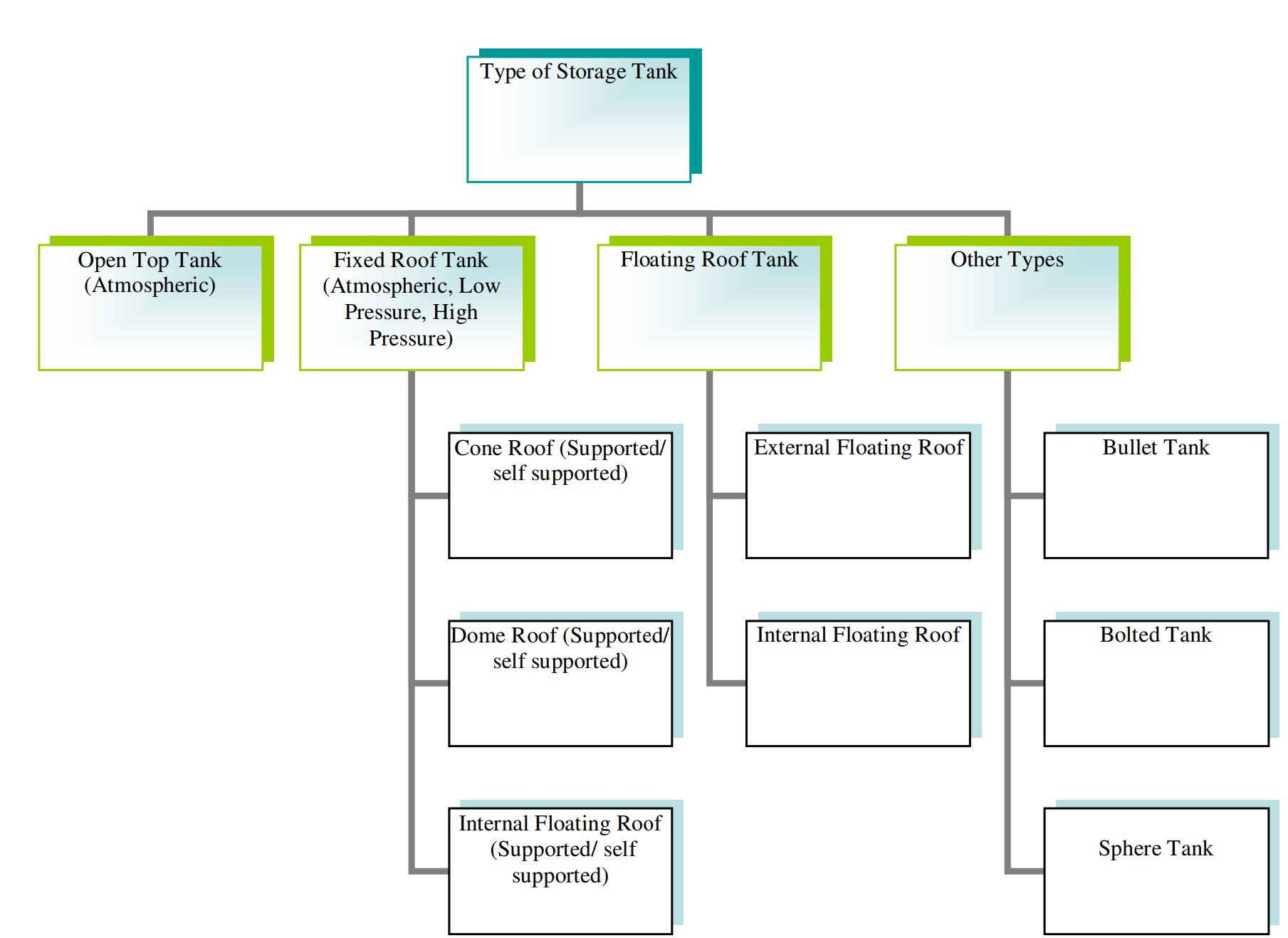

Chart 1: Illustrates various types of storage tanks.

Converting Existing Storage Tanks from EFR to IFR with Aluminum Dome Roof

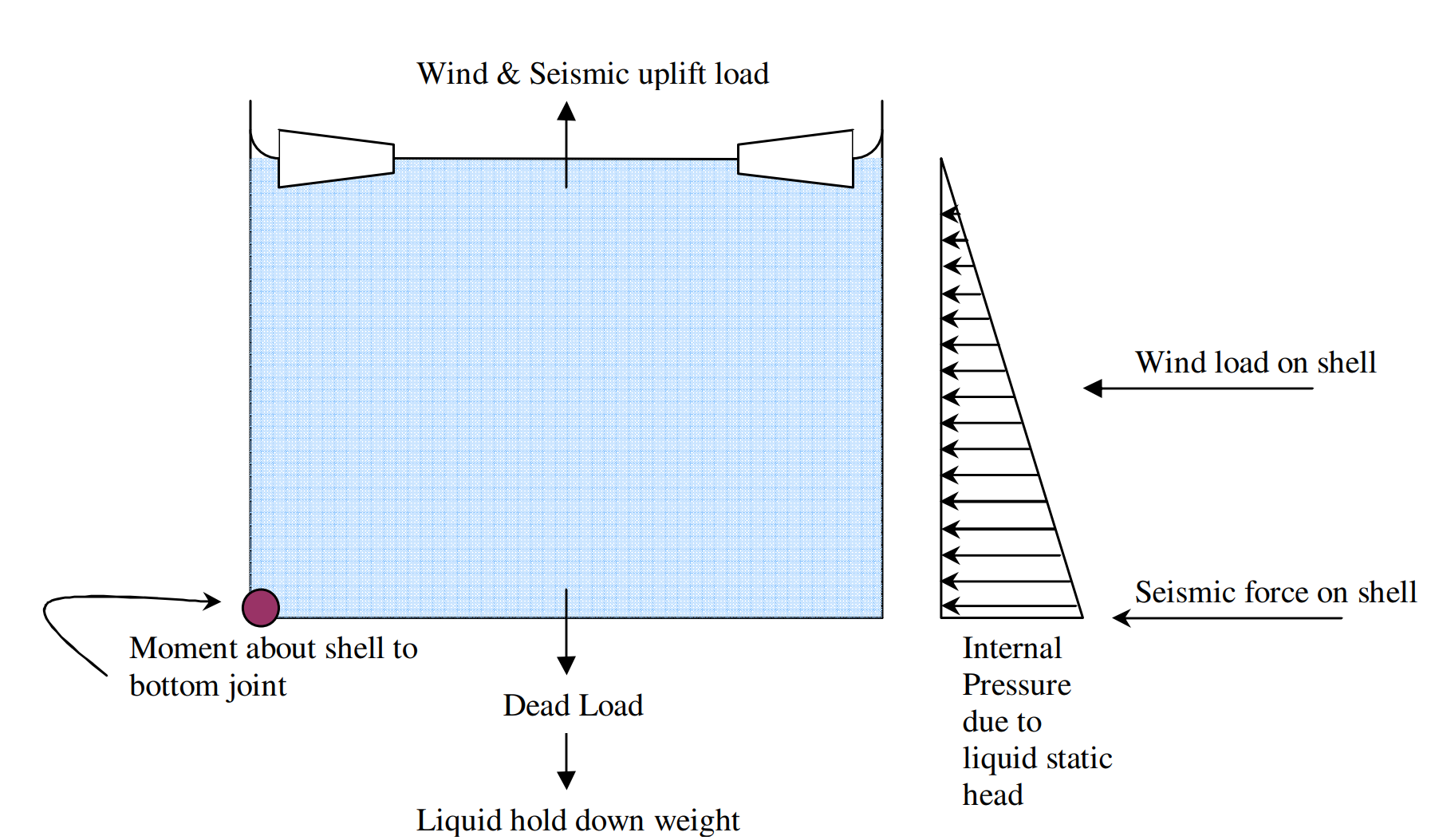

Converting an existing EFR storage tank to IFR with Dome Roof is possible, however it is recommended to reconsider complete design parameters. Aluminum dome roof is a light weight structure and it most of time does not have significant effect on the storage tank load. Internal floating roof does not have any effect on the storage tank, however stored product chemical properties have to be considered in order to avoid any corrosion effect. For example; sulphur content in crude oil determines the aluminum grade.

Images: 2 Loading Diagram on a Tank Shell

Benefits of IFR with Dome Roof Compare to EFR

-

- Lifespan : Aluminum has a longer lifespan than carbon steel.

- Maintenance cost: Carbon steel roof is corroded after some time, and it has to be painted regularly. To apply shot blasting, and painting on the storage tank roof is costly and requires serious safety measures. Moreover, the EFR sealing system has to be replaced periodically. Due to the regular movement, weather conditions and vapor effect, seals are deformed. This affects the performance of the EFR and increases risk.

- Performance: Combination of IFR with aluminum dome roof performs better than the EFR. The EFR storage tank is in direct contact with the environment and weather conditions; such as heat, rain, and snow affects its performance. Heat increases the emission losses. Rain has to be drained and increase the chance of corrosion. Finally, snow increases the load weight and increases the chance of sinking. Whereas, aluminum geodesic dome roof reduces the sun’s direct heat effect, and minimizes rain and heavy snow effect on the roof.

- Installation cost: Both IFR and aluminum dome roof are prefabricated lightweight structures. They can be easily shipped to the site in a container. You do not need to weld any parts and it can be quickly installed with bolts and nuts. Site installation is easy and does not require heavy lift, on the other hand carbon steel is a heavy structure. It requires a special lifting crew with various types of cranes. Each part has to be welded and tested on site. This is a long and costly process, which requires a lot of qualified manpower with special welding arrangements, however both geodesic aluminum and internal floating roof installation does not require any special equipment and qualified manpower. A single experienced supervisor can help the local team to install both equipment.

- Capacity: External floating roof takes more volume than an internal floating roof, therefore capacity of the same size tank is usually less.

Image 1 Crude Oil Storage Tank External Floating Roof Site Erection

- Installation time: Handling and installation of aluminum dome roof with IFR is much faster than EFR, because of non welded parts and light structure. EFR is difficult to handle and requires welding, which is a slow process.

- Safety: Aluminum dome roof can be installed on the ground and lifted easily without working at height. It does not require any paint, which is toxic and harmful for enviroment, so no need to take special precautions.

- Problems with EFR apparatus: Each EFR needs following apparatus in order to operate safely

- Image 3: EFR overtopped

- Image 4: Pontoon buckling [Tetsuaya, 2007)

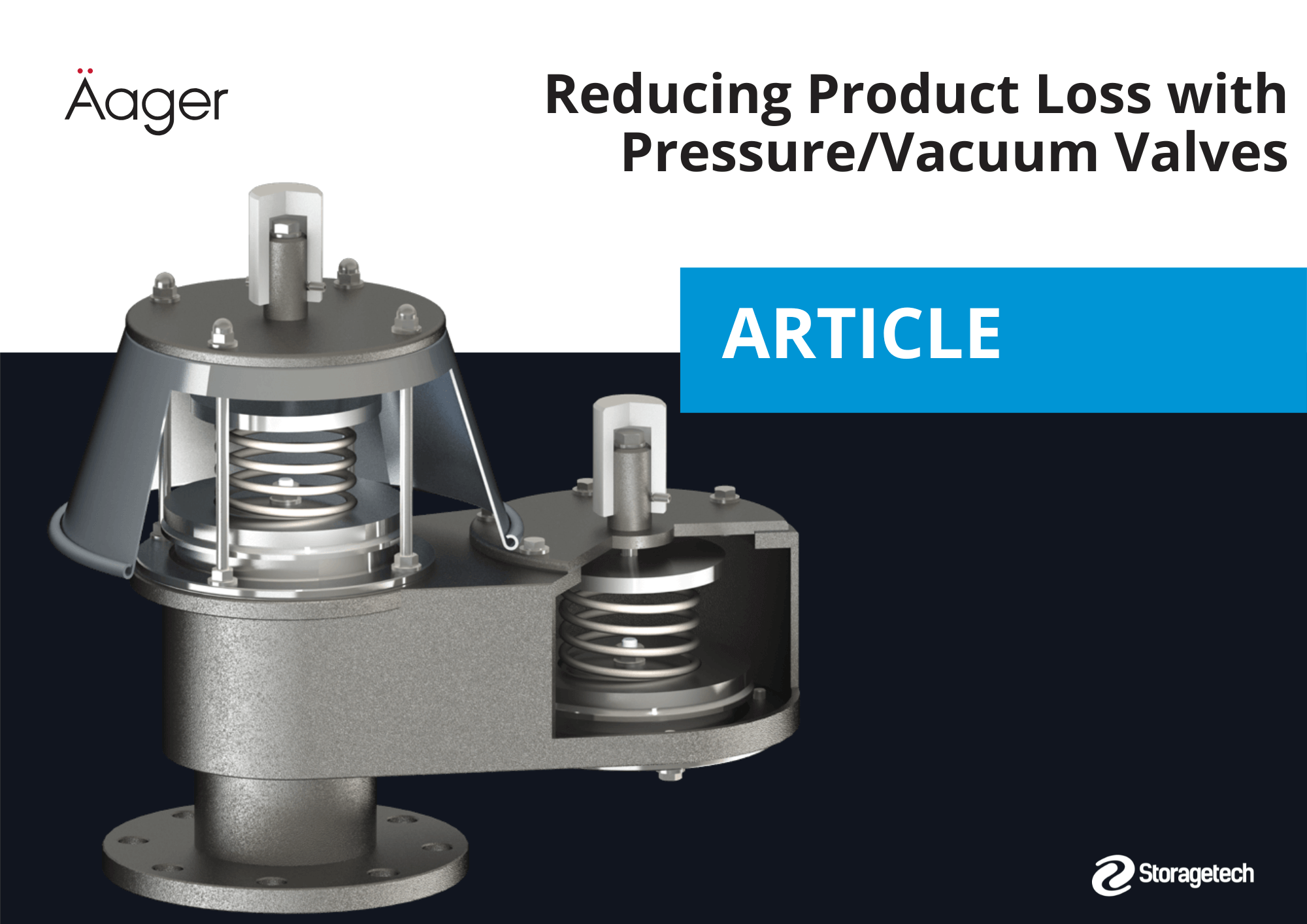

- Mechanical or non mechanical foam seals: Costly and has to be replaced preiodically.

- Water drain system: Failure of drain system can cause EFR to collapse due to the load. Flexi pipe drain systems are often stuck and do not let EFR to move. Swivel joint type drains leakages can also contaminate the stored product.

- Image 5: Flexible drainage system

- Rolling stairs: Stairs have to be maintained regularly in order to avoid getting stuck, otherwise it forces EFR to move in the opposite direction.

- Level indicator gauge pole cover: They are costly and require qualified technicians to install. Since it is directly in touch with the UV and weather conditions, it has to be replaced periodically.

- Ladder pole cover: Ladder pole covers change shape like are costly and require qualified technicians to install. Since it is directly in touch with the UV and weather conditions, it has to be replaced periodically.

- Leg Boots: Each EFR has multiple legs. Leg booths are costly and require qualified technicians to install. Since it is directly in touch with the UV and weather conditions, it has to be replaced periodically.

- Rim seal fire fighting system: Majority of the fires in external floating roof tanks start in the seal area between the floating roof and the shell, known as rim seal.

- Bleeder Vent: EFR breather valves usually do not function well as opposed to close top tanks. Tradinitally EFR vent is a simple mechanism made of carbon steel, and therefore fabricators manufacture them instead of sourcing from reliable breather valve manufacturers.