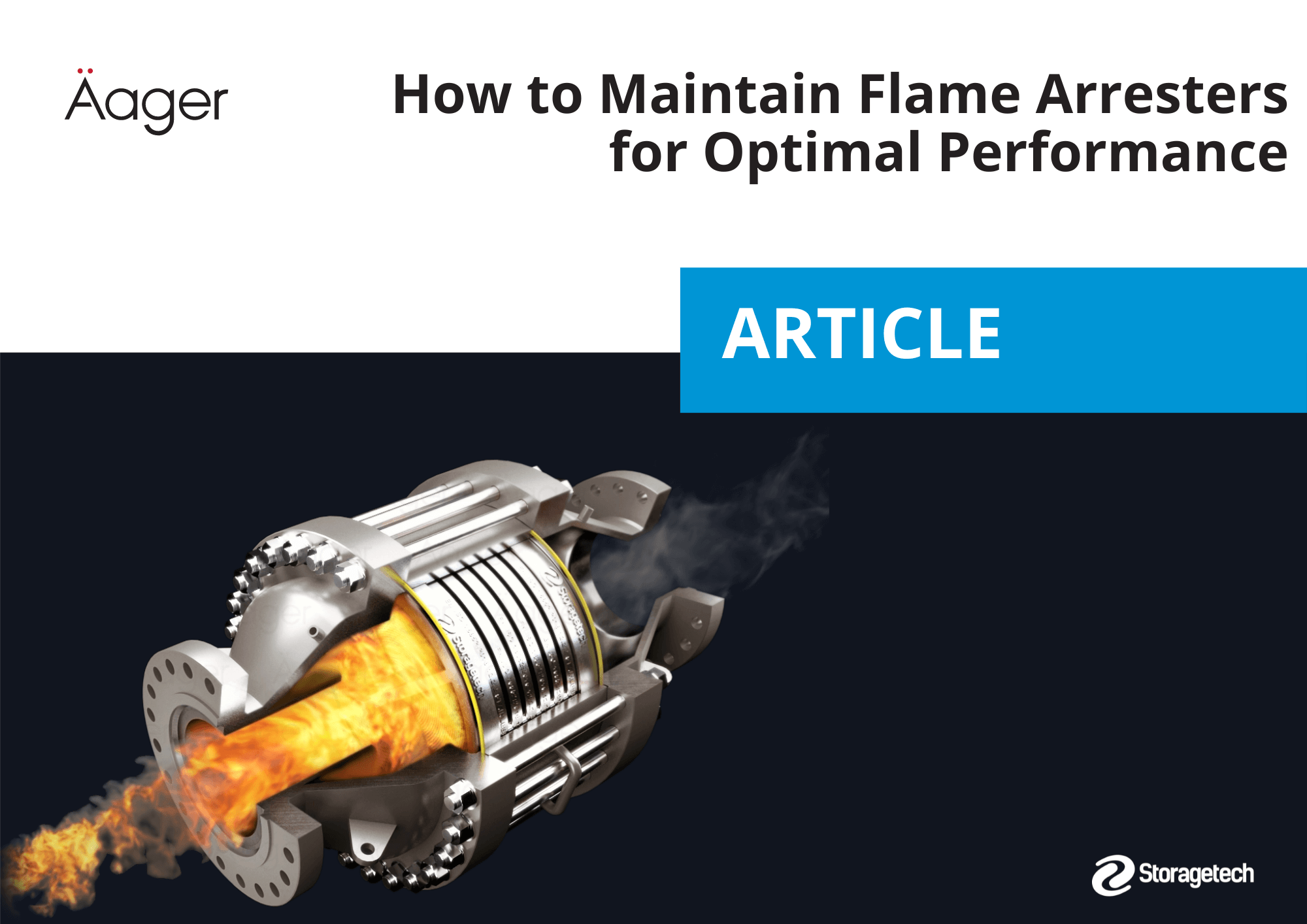

Flame arresters are essential safety devices designed to prevent the spread of flames in flammable gas or vapor mixtures. To ensure they function correctly and provide the necessary protection, regular maintenance is crucial. This guide provides a comprehensive overview of how to maintain flame arresters for optimal performance.

Understanding Flame Arresters

Flame arresters work by absorbing the heat of a flame front, reducing the temperature of the gas mixture below its ignition point, and preventing flame propagation. These devices are critical in various industries, including oil and gas, chemical processing, and pharmaceuticals, where the risk of explosion is high.

Importance of Regular Maintenance

Regular maintenance of flame arresters is vital for several reasons:

- Safety: Ensures the device is functioning correctly, preventing catastrophic explosions.

- Compliance: Meets industry regulations and standards.

- Efficiency: Maintains optimal performance, reducing downtime and operational disruptions.

- Longevity: Extends the lifespan of the flame arrester, providing long-term protection.

Maintenance Procedures

1. Visual Inspection

Frequency: Monthly

Steps:

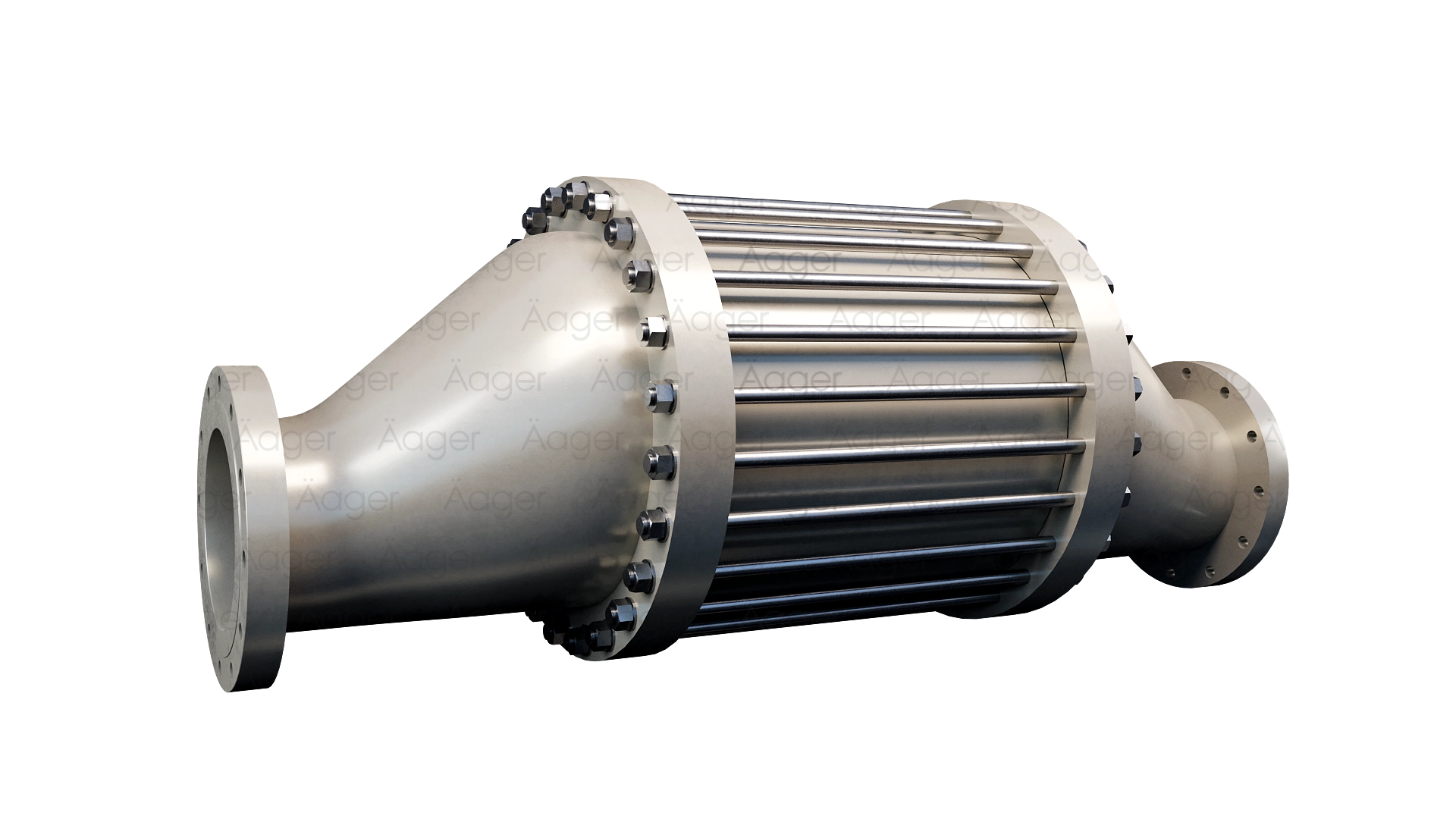

- External Condition: Check the external condition of the flame arrester for signs of corrosion, damage, or wear.

- Connections: Ensure all connections are secure and free from leaks.

- Protective Coating: Inspect the protective coating (if applicable) for any damage.

2. Cleaning

Frequency: Every 3-6 months, depending on the operating environment

Steps:

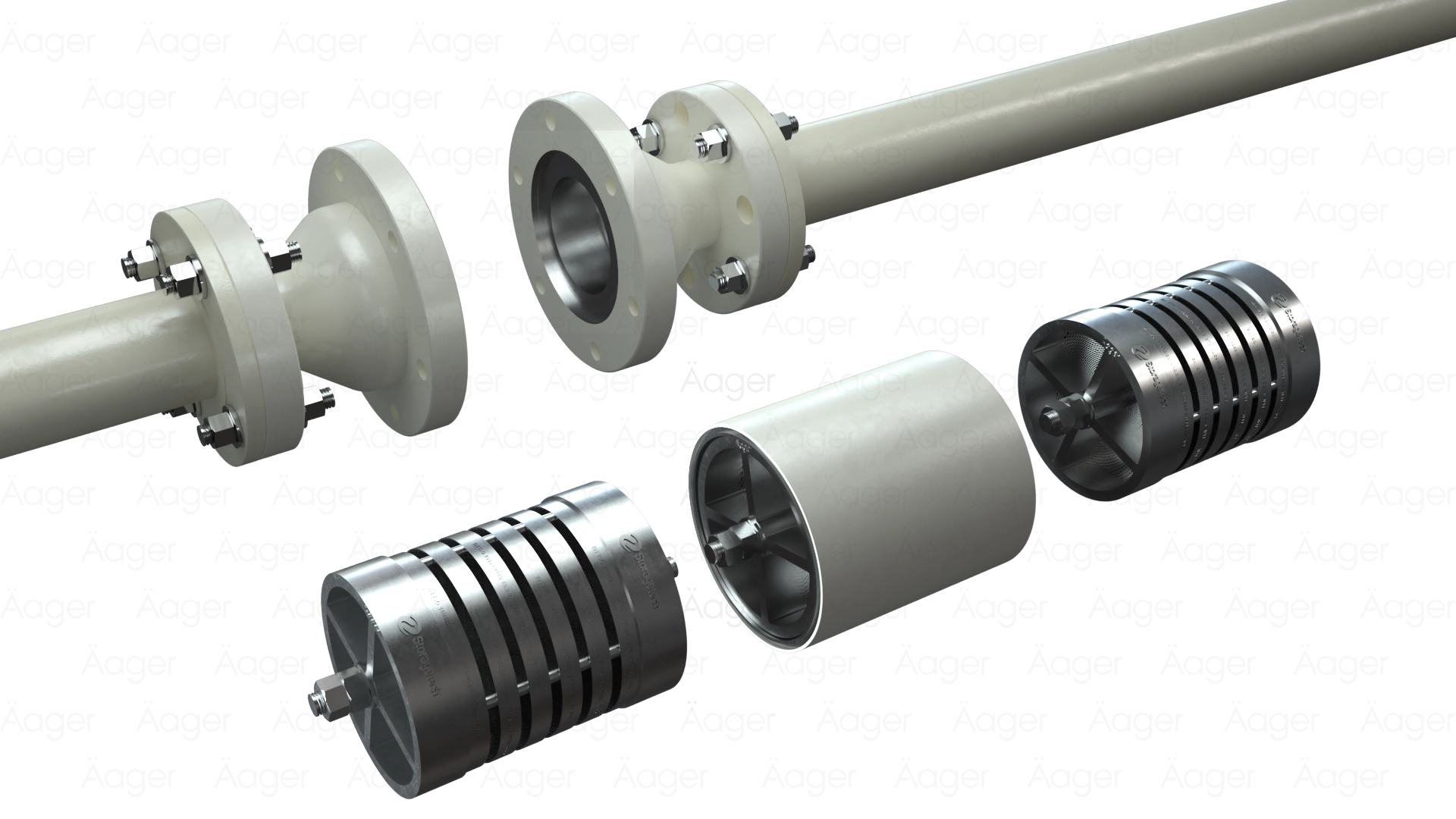

- Disassembly: Carefully disassemble the flame arrester according to the manufacturer’s instructions.

- Cleaning Methods:

- Mechanical Cleaning: Use brushes or compressed air to remove debris and particulate matter from the flame element.

- Chemical Cleaning: If necessary, use approved solvents to dissolve stubborn deposits. Ensure all chemical residues are thoroughly removed.

- Reassembly: Reassemble the flame arrester, ensuring all parts are correctly aligned and securely fastened.

3. Functional Testing

Frequency: Annually or as specified by the manufacturer

Steps:

- Flow Test: Conduct a flow test to ensure the flame arrester allows the correct amount of gas or vapor to pass through.

- Pressure Drop Test: Measure the pressure drop across the flame arrester to ensure it is within acceptable limits.

- Ignition Test: Perform an ignition test (if safe and practical) to verify the flame arrester’s ability to extinguish a flame front.

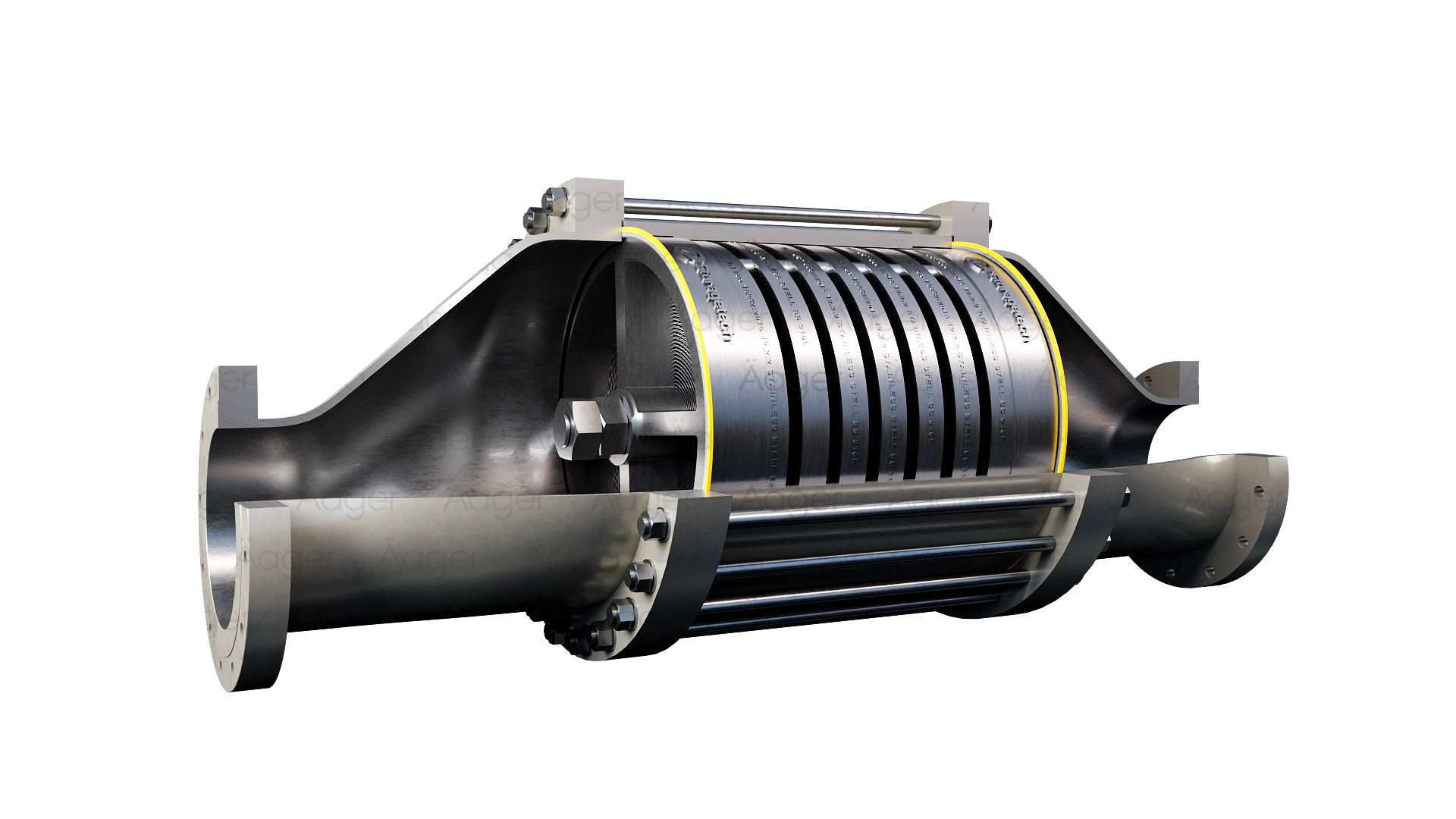

4. Detailed Internal Inspection

Frequency: Every 2-3 years or as specified by the manufacturer

Steps:

- Element Inspection: Remove the flame element and inspect for any signs of warping, corrosion, or clogging.

- Housing Inspection: Check the internal housing for signs of wear, corrosion, or damage.

- Replacement: Replace any worn or damaged parts with manufacturer-approved components.

Best Practices for Maintenance

1. Follow Manufacturer Guidelines

Always adhere to the maintenance schedule and procedures outlined in the manufacturer’s manual. This ensures compliance with industry standards and preserves the warranty.

2. Use Proper Tools and Equipment

Ensure all maintenance is performed using the correct tools and equipment. This prevents damage to the flame arrester and ensures safe operation.

3. Maintain Records

Keep detailed records of all maintenance activities, including inspections, cleaning, and testing. This helps track the performance of the flame arrester and identify any recurring issues.

4. Train Personnel

Ensure all personnel involved in the maintenance of flame arresters are adequately trained and understand the importance of following proper procedures.

Troubleshooting Common Issues

1. Clogging

Symptoms: Reduced flow rate, increased pressure drop

Solution: Regular cleaning and inspection to remove debris and particulate matter. Consider installing a pre-filter to reduce the ingress of particulates.

2. Corrosion

Symptoms: Visible signs of rust or pitting, compromised structural integrity

Solution: Use flame arresters made from corrosion-resistant materials like stainless steel or apply a protective coating. Regularly inspect and replace corroded parts.

3. Mechanical Damage

Symptoms: Dents, cracks, or warping of the flame element or housing

Solution: Inspect for damage during routine maintenance. Replace damaged components immediately to maintain safety and performance.

Storagetech’s Flame Arrester Maintenance Services

Storagetech offers comprehensive maintenance services for flame arresters, ensuring they operate at peak performance. Our services include:

- Routine Inspections: Regular visual and functional inspections to identify potential issues early.

- Cleaning and Repair: Professional cleaning and repair services to maintain optimal performance.

- Testing and Certification: Detailed testing and certification to ensure compliance with industry standards.

For more information on Storagetech’s flame arrester maintenance services, visit Storagetech Flame Arresters.

Maintaining flame arresters is crucial for ensuring safety and operational efficiency in industries handling flammable gases and vapors. By following a regular maintenance schedule, using the correct tools and techniques, and adhering to manufacturer guidelines, you can ensure your flame arresters provide reliable protection. For expert maintenance services, consider partnering with Storagetech, a leader in industrial safety solutions.

Kutay EMİCİ

Assistant Sales Engineer