Flame arresters are critical safety devices used to prevent the propagation of flames through flammable gas or vapor mixtures. Their application spans various industries, including chemical processing, oil and gas, pharmaceuticals, water treatment, and food and beverage. This detailed article explores the science behind flame arresters, their working principles, and their importance in ensuring safety in industrial processes.

Basic Principles of Flame Arresters — How Flame Arresters Work

Flame Propagation

Flames propagate through the combustion of flammable gases or vapors mixed with air. This combustion process involves a complex chain reaction where heat from the flame front ignites the adjacent gas mixture, allowing the flame to travel through the medium.

Quenching Distance

The quenching distance is the minimum gap between two surfaces through which a flame can no longer propagate. Flame arresters utilize materials and structures that create passages smaller than the quenching distance of the gas mixture, effectively stopping the flame.

Types of Flame Arresters

End-of-Line Flame Arresters

End-of-line flame arresters are installed at the end of a pipeline or vent. They are typically used to prevent external flames from entering a storage tank or process vessel.

Example Application: Storage tanks for volatile organic compounds (VOCs) often use end-of-line flame arresters to prevent external ignition sources from causing internal explosions.

Inline Flame Arresters

Inline flame arresters are installed within a pipeline. They prevent flames from traveling through the pipeline, protecting downstream equipment.

Example Application: Gas pipelines in chemical processing plants use inline flame arresters to stop flames from traveling through the system and causing widespread damage.

Detonation Flame Arresters

Detonation flame arresters are designed to stop high-velocity, supersonic flames resulting from detonations. These devices are robust and can withstand the pressure and shock waves generated by detonations.

Example Application: Oil refineries use detonation flame arresters in high-pressure gas lines to prevent catastrophic explosions.

Construction and Materials

Flame arresters are constructed using materials that can withstand high temperatures and corrosive environments. Common materials include:

- Stainless Steel: Used for its corrosion resistance and high-temperature strength.

- Nickel Alloys: Employed in highly corrosive environments or where high-temperature strength is critical.

- Inconel: A high-performance material used in extreme conditions due to its excellent corrosion resistance and ability to withstand high temperatures.

Working Mechanism — How Flame Arresters Work

Heat Absorption and Quenching

The primary mechanism by which flame arresters stop flame propagation is by absorbing heat. Flame arresters consist of numerous narrow passages or elements made from crimped metal ribbons or mesh. When a flame front encounters the flame arrester, the heat from the flame is absorbed by the metal, reducing the temperature of the gas mixture below its ignition point.

Turbulence and Flow Distribution

Flame arresters create turbulence in the gas flow, which helps in dispersing the flame front. This turbulence increases the efficiency of heat transfer from the flame to the arrester elements, enhancing the quenching effect.

Pressure Drop Considerations

While designing flame arresters, it is crucial to balance the quenching efficiency with the pressure drop across the device. A high pressure drop can impact the efficiency of the overall system. Engineers must ensure that the flame arrester provides adequate protection without significantly hindering the process flow.

Detailed Working Examples

Chemical Processing Industry

In the chemical processing industry, flame arresters are vital for protecting storage tanks and pipelines containing flammable chemicals. For instance, a facility storing ethylene employs end-of-line flame arresters on tank vents to prevent external ignition sources from causing explosions. These arresters use stainless steel crimped ribbon elements to absorb heat and quench flames effectively.

Oil and Gas Industry

Oil and gas facilities use inline flame arresters to safeguard pipelines transporting volatile hydrocarbons. In a typical application, an oil refinery installs inline flame arresters in gas pipelines leading to processing units. These arresters, made from nickel alloys, withstand the corrosive environment and high temperatures, ensuring the safety of the entire processing unit.

Pharmaceutical Industry

Pharmaceutical plants often handle flammable solvents. To prevent flames from spreading through solvent recovery systems, these facilities use end-of-line flame arresters. These arresters, constructed from high-grade stainless steel, effectively quench flames and protect the sensitive processing equipment.

Standards and Compliance

Flame arresters must comply with various international standards to ensure their effectiveness and reliability. Key standards include:

- ISO 16852: General requirements and test methods for flame arresters.

- NFPA 69: Standard on explosion prevention systems.

- API 2000: Venting atmospheric and low-pressure storage tanks.

- ATEX: Equipment for explosive atmospheres.

Compliance with these standards ensures that flame arresters are tested and certified to provide the necessary protection in hazardous environments.

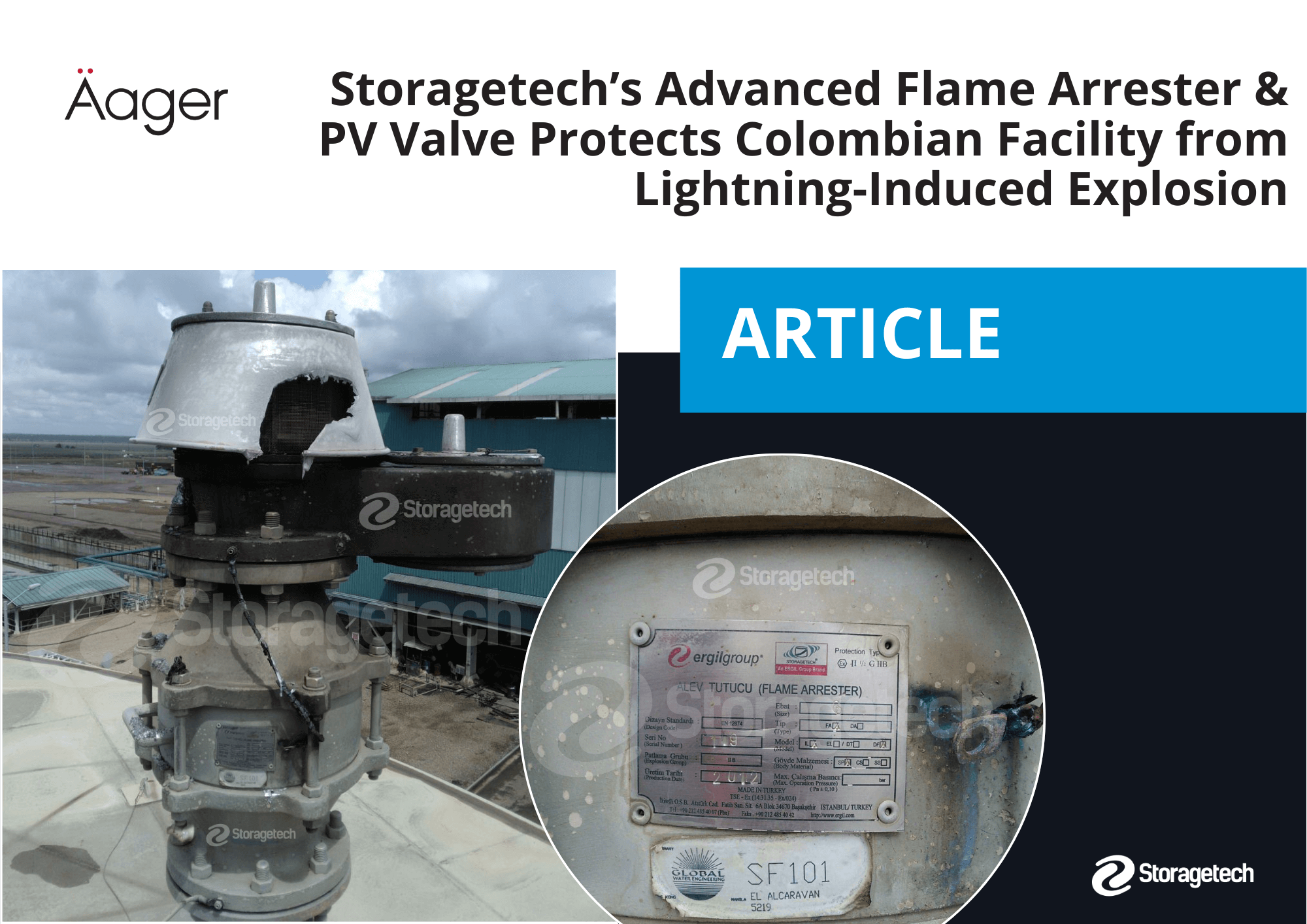

ERGIL’s Expertise in Flame Arresters

ERGIL, with over 40 years of experience, specializes in designing and manufacturing high-quality flame arresters tailored to meet the specific needs of various industries. Our flame arresters are engineered to the highest standards, ensuring safety and reliability in the most demanding conditions.

Product Range:

- End-of-Line Flame Arresters: Ideal for protecting storage tanks and process vessels.

- Inline Flame Arresters: Suitable for gas pipelines and processing units.

- Detonation Flame Arresters: Designed for high-pressure and high-velocity gas systems.

Key Features:

- High-Performance Materials: Stainless steel, nickel alloys, and Inconel.

- Advanced Design: Optimized for minimal pressure drop and maximum quenching efficiency.

- Compliance: Adherence to ISO, NFPA, API, and ATEX standards.

Flame arresters are indispensable safety devices in various industries, providing critical protection against the propagation of flames and explosions. Understanding the science behind their operation, construction, and application helps in selecting the right flame arrester for specific needs. ERGIL’s expertise and comprehensive product range ensure that industrial facilities are equipped with the best possible solutions for flame arresting, enhancing safety and operational efficiency.

For more information about our flame arresters and other safety solutions, visit Storagetech™ Flame Arrestors.

How Flame Arresters Work