Deflagration Arrester: The Essential Safety Device Protecting Industrial Systems

In industrial environments where flammable gases and vapors are handled, the risk of explosion is ever-present. A deflagration arrester plays a crucial role in mitigating this danger. It prevents flame fronts from traveling through piping or ventilation systems, protecting storage tanks, fuel terminals, and processing plants from catastrophic explosions.

While flame arresters have long been a staple in global safety systems, the deflagration arrester represents a refined, high-performance solution — particularly valued in the United States, where safety standards are among the most stringent worldwide.

Understanding How a Deflagration Arrester Works

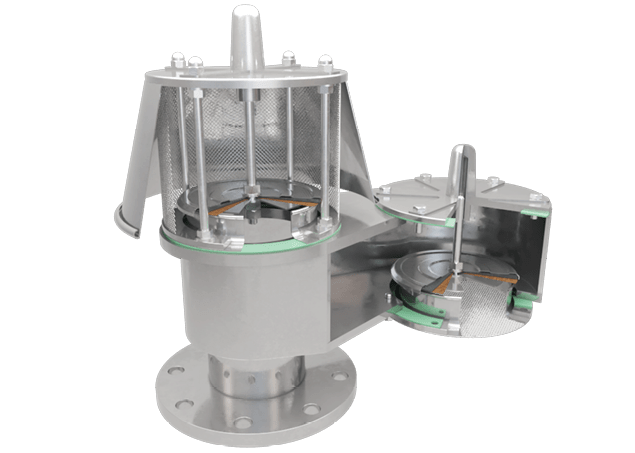

A deflagration arrester functions by quenching a flame before it can propagate. Inside the device lies a precision-engineered metal element — often a crimped ribbon or mesh — designed to dissipate heat and absorb the energy of the flame. As hot gases pass through, the arrester cools them below their ignition temperature, effectively extinguishing the flame front.

In simple terms, it acts as a fire barrier within a pipeline or venting system, preventing flames from traveling back into a potentially explosive mixture.

StorageTech and similar manufacturers design these devices to withstand harsh environments, ensuring minimal pressure drop, corrosion resistance, and compliance with global safety standards.

Applications Across U.S. Industries

In the United States, deflagration arresters are integral to sectors such as:

-

Petrochemical and oil refining: Installed on vapor recovery units, tank vents, and flare systems to prevent flashback.

-

Fuel storage terminals: Used on fixed roof tanks and pipelines where volatile hydrocarbons are stored.

-

Pharmaceutical and chemical plants: Protect process vessels from flame transmission during volatile reactions.

-

Biogas and wastewater treatment: Prevent ignition sources from spreading through gas lines.

-

Marine and aviation fuel systems: Ensure compliance with U.S. Coast Guard and FAA safety regulations.

In each of these environments, deflagration arresters safeguard not only physical assets but also human lives, environmental safety, and operational continuity.

deflagration arrester

The U.S. Regulatory Framework

In the American market, the design and installation of deflagration arresters are guided by several authoritative standards, including:

-

NFPA 67 – Standard for Explosion Protection by Deflagration Venting

-

API 2028 – Flame Arresters for Vents of Tanks Storing Petroleum Products

-

OSHA and EPA regulations for hazardous atmosphere control

-

UL and FM certifications for equipment reliability

Manufacturers supplying to the U.S. must meet these standards to ensure that every product performs reliably under the most demanding conditions. For companies like StorageTech, adherence to these codes not only ensures compliance but builds trust among safety engineers and facility operators.

Deflagration vs. Detonation Arresters

Though often used interchangeably, deflagration and detonation arresters differ in their intended application:

-

A deflagration arrester is designed for subsonic flame propagation, typically occurring in short pipelines or near the ignition source.

-

A detonation arrester, by contrast, can withstand supersonic combustion waves, making it suitable for long pipelines or systems where high-pressure shocks can occur.

Choosing the correct type is critical. Using a deflagration arrester in a detonation scenario could result in failure — which is why engineering evaluation and correct certification are vital.

Design and Maintenance Best Practices

For optimal safety, the following guidelines are widely adopted in the U.S. industry:

-

Proper Sizing and Orientation: The arrester must match the flow rate, gas composition, and system pressure.

-

Regular Inspection: Periodic removal and cleaning are essential to prevent blockage or corrosion buildup.

-

Testing and Certification: Only arresters tested under conditions defined by ISO 16852 or API 2028 should be used.

-

Integration with Venting Systems: In tank applications, the arrester is often paired with pressure/vacuum relief valves for dual safety.

StorageTech’s range of deflagration arresters incorporates modular flame quenching elements and weather-resistant housings, making them suitable for outdoor installations and marine environments.

Technological Advances and Market Trends

Modern deflagration arresters are evolving with smart manufacturing and digital monitoring. U.S. facilities increasingly demand devices that integrate with IoT-enabled safety systems, allowing operators to monitor pressure drops, temperature changes, and maintenance schedules in real time.

The adoption of stainless-steel flame elements, explosion-proof housings, and high-flow geometries has also expanded the lifespan and efficiency of these arresters. As environmental regulations tighten, their role in emission control systems is becoming even more prominent.

Flame Arrester

StorageTech’s Contribution to Global Safety

As a global manufacturer with decades of experience in tank safety equipment, StorageTech provides high-quality deflagration arresters designed to meet NFPA, ATEX, and ISO standards. The company’s engineering focus lies in delivering reliable, low-maintenance, and corrosion-resistant solutions for fuel, chemical, and energy industries.

By aligning its product line with U.S. performance requirements and European quality standards, StorageTech bridges the gap between international markets — offering OEMs, integrators, and operators equipment they can trust in mission-critical environments.

Conclusion

The deflagration arrester stands as one of the most vital safety devices in modern industrial infrastructure. From chemical refineries to fuel storage terminals across the United States, it acts as the silent guardian preventing flames from escalating into explosions.

Through innovation, regulatory compliance, and quality engineering, companies like StorageTech ensure that industrial operations remain safe, efficient, and sustainable.

Whether referred to as a flame trap, flame arrester, or detonation barrier, the underlying goal remains the same — to stop fire before it starts a disaster.