Company: Aager

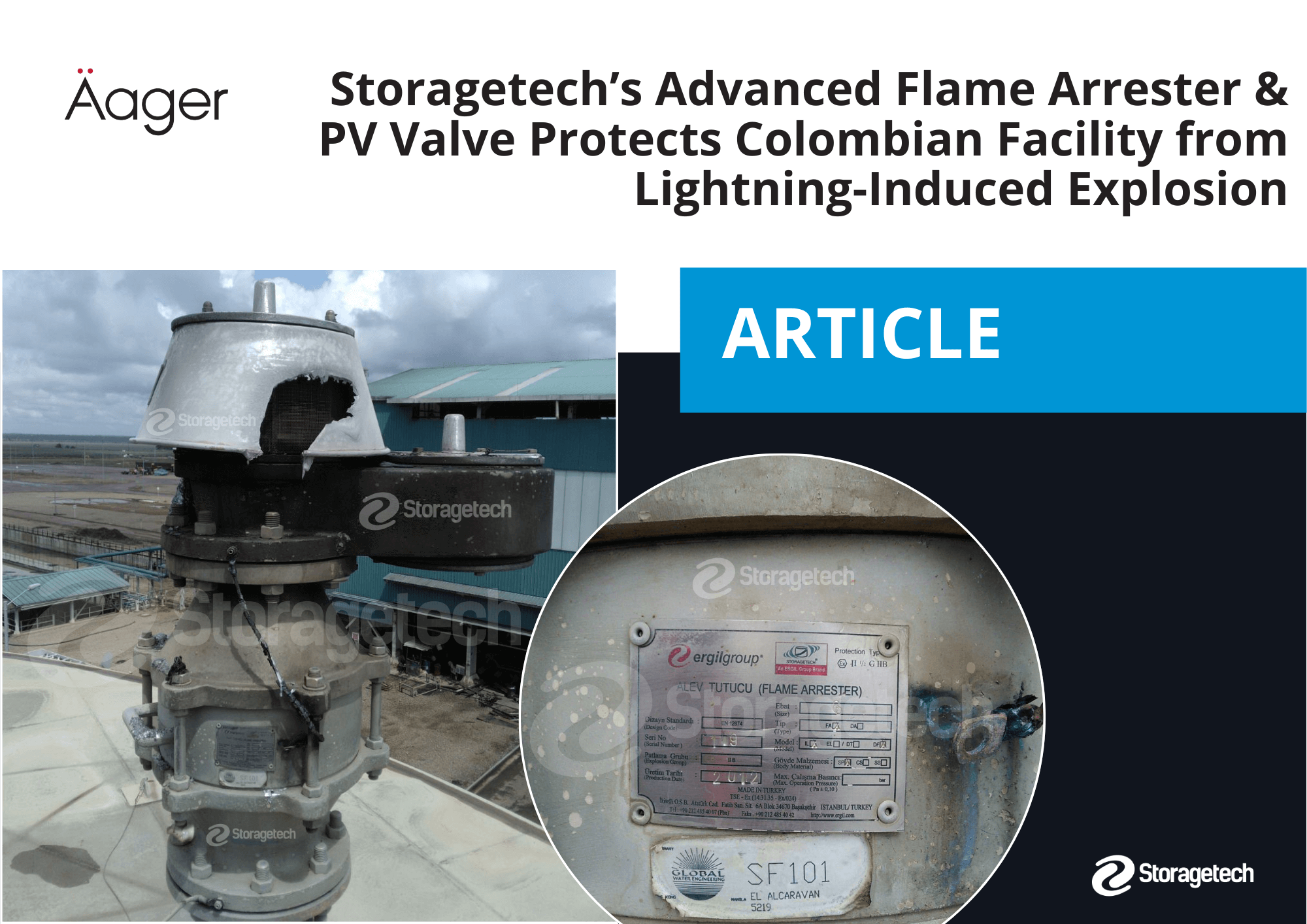

Client Location: Colombia

Product: Combination Flame Arrester + Pressure Vacuum Valve (Model: SF101)

Background

Our client, an industrial facility in Colombia, operates critical storage tanks containing flammable liquids. Ensuring tank safety against overpressure, vacuum conditions, and external ignition sources is paramount to maintaining operational safety and continuity.

As part of their risk management strategy, they selected our SF101 Combination Pressure Vacuum Valve (PVV) with Flame Arrester, a rugged and field-proven solution designed for hazardous environments. Unlike compact integrated units on the market, our combination unit is engineered for superior mechanical strength and layered protection.

The Incident

In October 2017, the facility experienced a severe thunderstorm. During the storm, one of the storage tanks sustained a direct lightning strike to the venting system — a worst-case scenario for storage tank safety.

A lightning strike at the tank vent is a critical risk: it can ignite flammable vapors escaping through the vent, allowing flame propagation directly into the tank’s vapor space, potentially causing catastrophic explosion and facility-wide fire.

Product Response & Performance

Despite the intensity of the lightning strike, the SF101 system performed flawlessly:

- The PVV cap absorbed the initial mechanical and thermal impact of the lightning strike. While the external cap was visibly damaged, it shielded the internal mechanisms.

- The flame arrester element, positioned immediately below the PVV, effectively quenched the flame front. Its robust stainless-steel matrix rapidly cooled the flame, preventing ignition of flammable vapors inside the tank.

- No flame propagation occurred. The tank’s contents remained safely isolated, and no internal damage was reported.

- Only the external vent cap required replacement. The core functional components — including the flame arrester element — remained intact and operational.

Why the Combination Design Was Critical

Unlike compact, integrated PVV/flame arrester designs (such as those offered by competitors), our combination system provides distinct advantages in severe conditions:

1. First Line of Defense: PVV Positioned on Top

- The PVV takes the first impact of external hazards like lightning, protecting the flame arrester below.

- Competitor integrated units lack this physical separation, making them more vulnerable.

2. Mechanical Robustness

- Separate, heavy-duty bodies withstand physical damage better than integrated units with thinner walls.

- Post-incident inspection confirmed the structural integrity of our system.

3. Independent Maintenance

- Damaged parts (like the PVV cap) can be replaced independently, reducing maintenance time and cost.

- Integrated units often require full replacement if any part is compromised.

4. Superior Airflow Management

- Our combination system provides better flow capacity, managing both normal breathing and emergency venting with lower pressure drops.

5. Redundant Safety Layers

- Dual protection: PVV handles tank breathing and surge relief, while the flame arrester ensures flame quenching.

- Integrated units consolidate both functions, risking total failure under extreme stress.

Outcome

✅ No injuries reported

✅ No damage to the tank shell or stored product

✅ Zero environmental impact

✅ Minimal downtime — only cap replacement was needed

✅ Customer operations continued safely

The incident demonstrated the critical importance of investing in robust safety equipment designed for real-world hazards. Our system proved its reliability and effectiveness under extreme circumstances, protecting millions of dollars in infrastructure and assets.

Conclusion

This case is a powerful demonstration of how Ergili Group’s commitment to superior engineering delivers real-world safety benefits. In hazardous environments where lightning strikes are a reality, our combination PVV and Flame Arrester system outperforms integrated solutions, offering:

- Higher mechanical strength

- Redundant protection layers

- Superior maintenance flexibility

Our customer in Colombia avoided a catastrophic event, and their facility continues to operate safely thanks to this robust design.

Supporting Materials

📸 Incident photos showing the damaged cap and intact flame arrester

📩 Customer communication confirming performance and outcomes

🛠 Maintenance report confirming system integrity

Mohammed HASSAN

Technical Coordinator