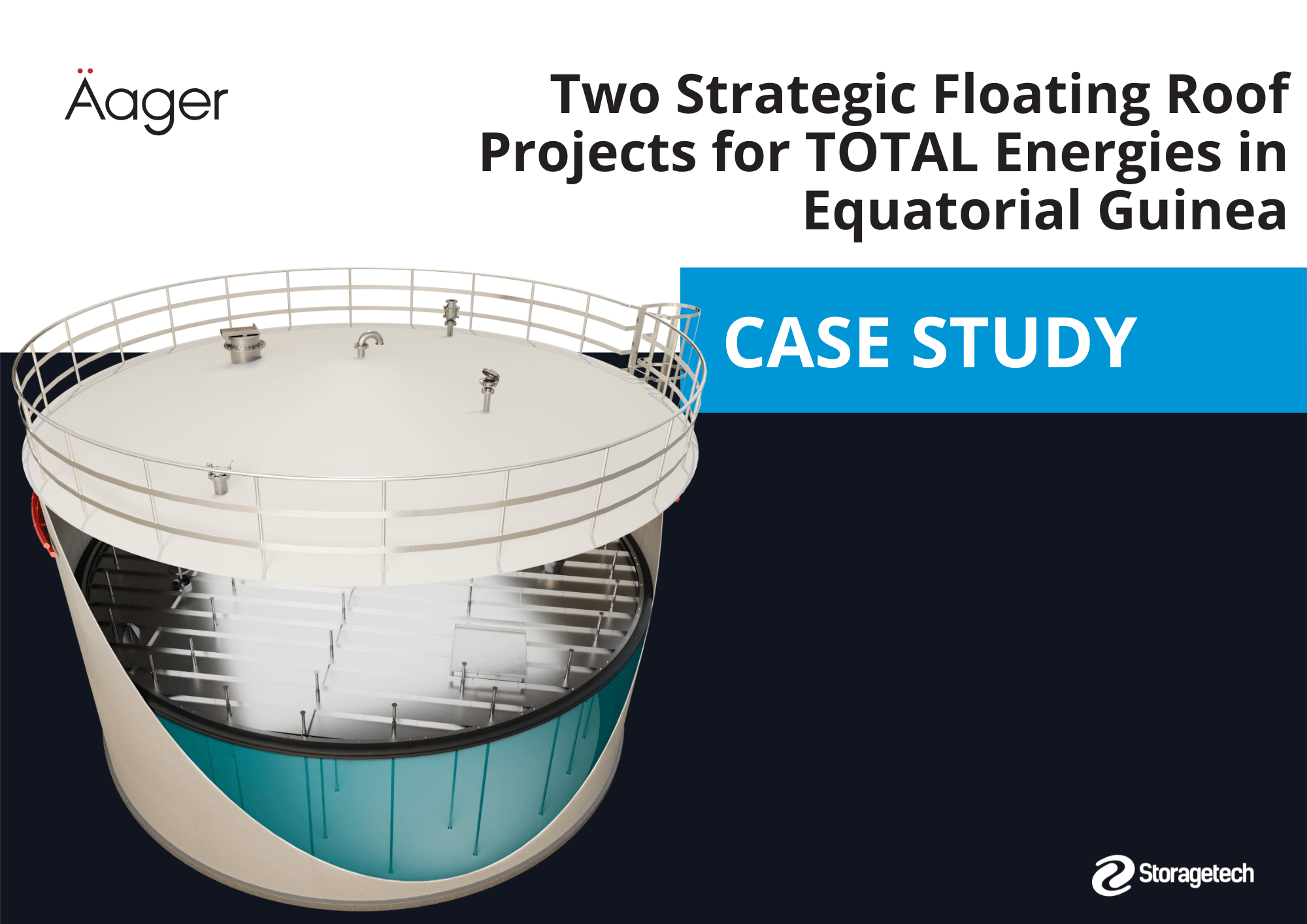

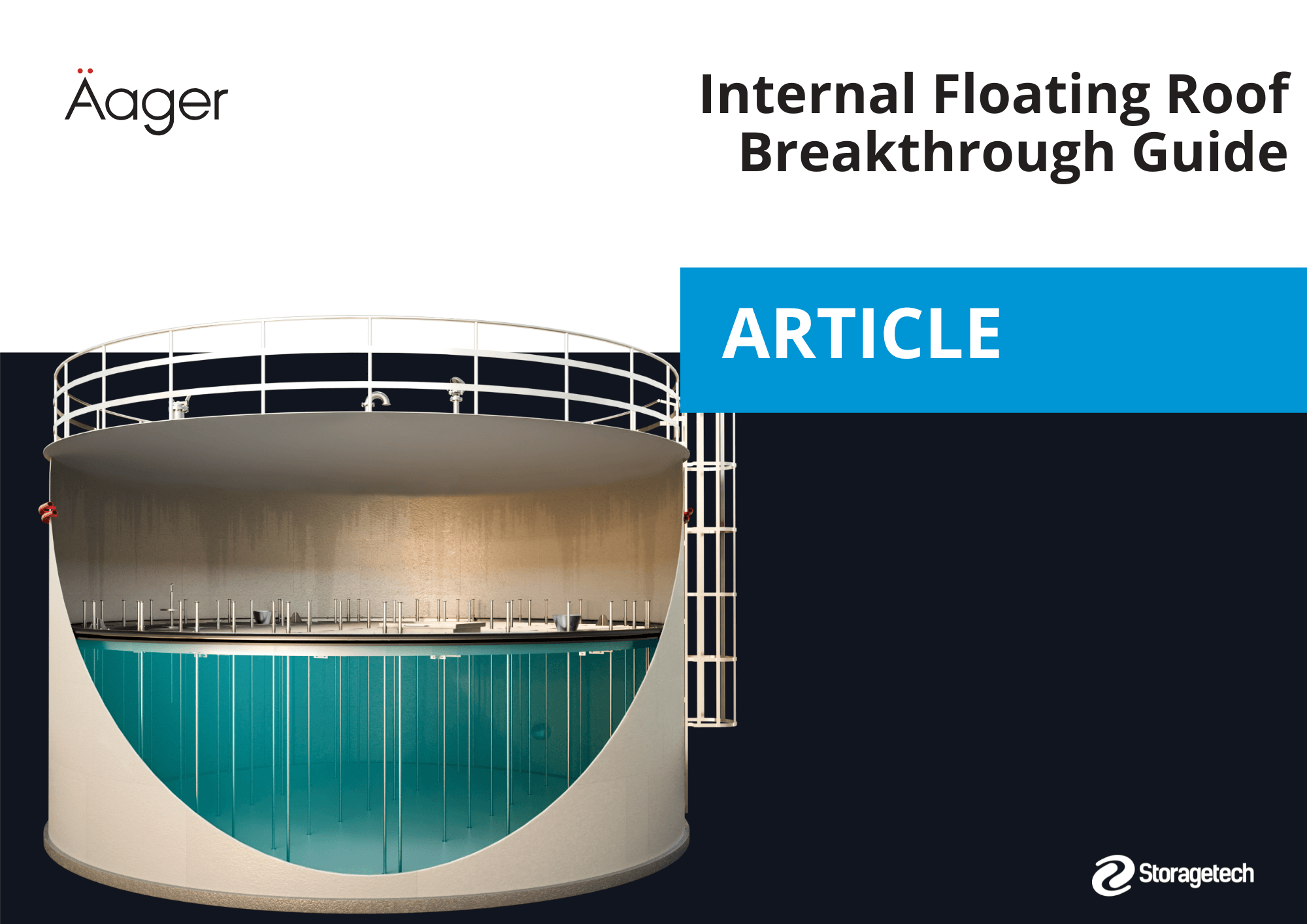

An internal floating roof is one of the most direct ways to cut vaporization losses in an atmospheric storage tank. It sits on the liquid surface inside the tank and “floats” up and down as product level changes. That simple idea delivers big results: fewer vapors in the tank’s vapor space, lower product loss, and better control of emissions and odor.

If you’ve ever heard someone say, “A tank is just a big container,” you already know that’s only half true. Tanks breathe. They heat up. They cool down. And every temperature swing can drive vapor losses. With an internal floating roof, you reduce the free vapor space, limit evaporation, and keep more product where it belongs.

This guide explains how an internal floating roof works, the main design types, how seals matter, and what to look for during selection, installation, and maintenance. It is written in plain English, with practical tips you can use in real projects.

1. Internal Floating Roof Basics

An internal floating roof is installed inside a fixed-roof storage tank. It floats directly on the stored liquid. When the tank is filled, the internal floating roof rises. When the tank is emptied, it lowers. This movement is not powered by motors. It is driven by buoyancy, like a wide, engineered raft.

What an internal floating roof does inside a tank

The main job of an internal floating roof is to reduce the vapor space above the liquid. Less vapor space usually means less evaporation. It also helps stabilize tank breathing behavior during daily temperature swings. In simple terms: it helps keep vapors down and product in.

Key benefits you typically target with an internal floating roof:

-

Reduced evaporation losses (often the primary driver)

-

Lower VOC emissions and odor potential (project-dependent)

-

Improved product quality by limiting exposure to air (for sensitive products)

-

Better safety posture by reducing vapor accumulation (when correctly specified)

-

Operational savings over time, especially on frequently cycled tanks

Where it’s used

An internal floating roof is common in:

-

Refined products (like gasoline blend components, naphtha, Jet fuel, diesel—application and spec dependent)

-

Crude or condensate service (site rules and product volatility matter)

-

Chemical storage where vapor control is required

-

Terminals and tank farms with emissions targets

Not every tank is a good candidate. If the liquid is very viscous, full of solids, or forms heavy sludge, an internal floating roof may need special design features (or may not be suitable). That’s why service conditions matter as much as the tank diameter.

The “why” in one sentence

A well-designed internal floating roof reduces vaporization by minimizing the vapor space and sealing the rim area, which helps cut losses and supports safer, cleaner operation.

2. Types and Designs

Not all internal floating roof systems are the same. The deck style, buoyancy method, materials, and seal design determine how well it performs and how easy it is to maintain.

Pontoon vs. full-contact designs

Two very common styles are:

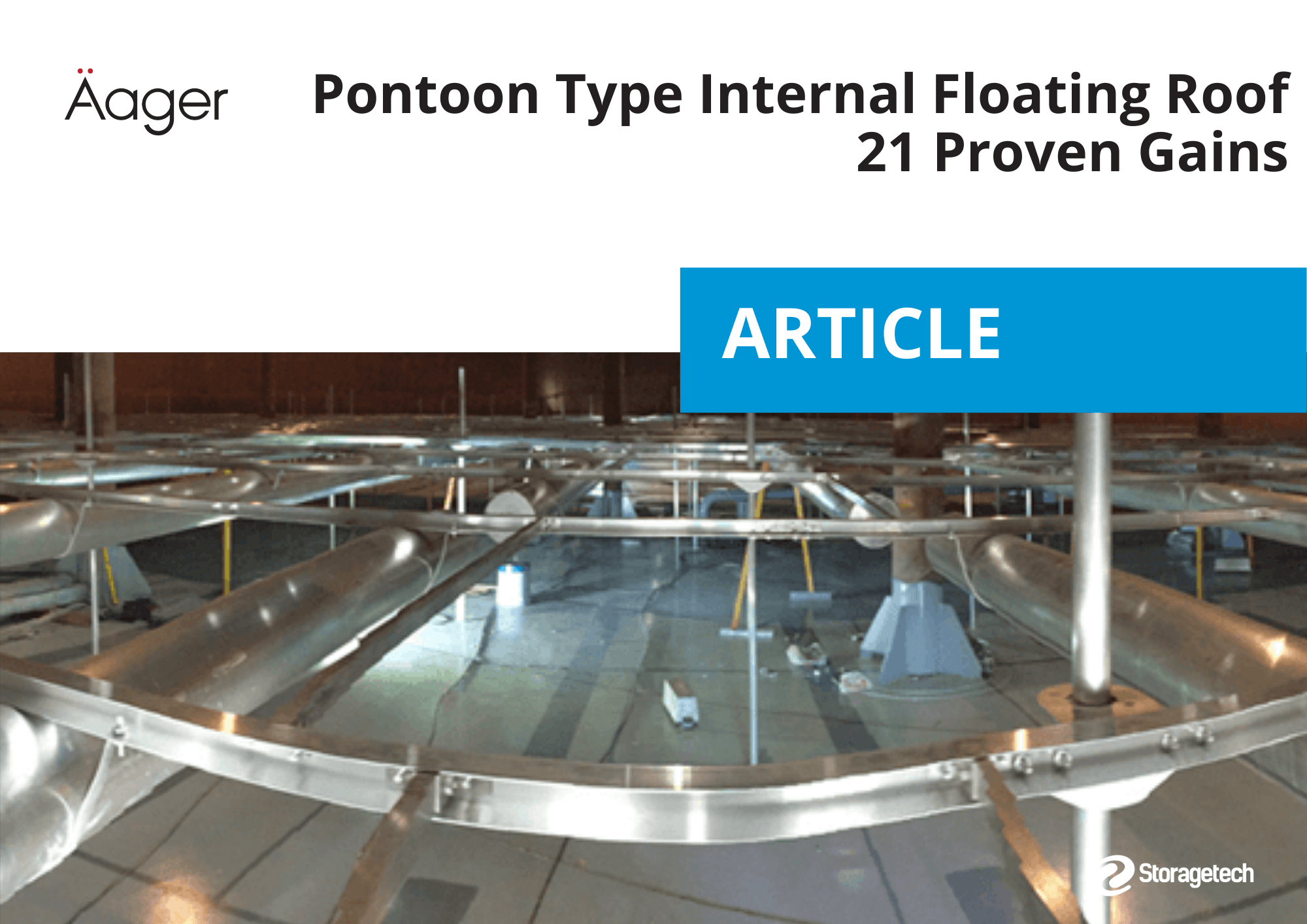

1) Pontoon deck internal floating roof

A pontoon design uses buoyant compartments around the perimeter (and sometimes internal pontoons). The center deck may be lighter. This can be a cost-effective approach, and it can be robust when built well.

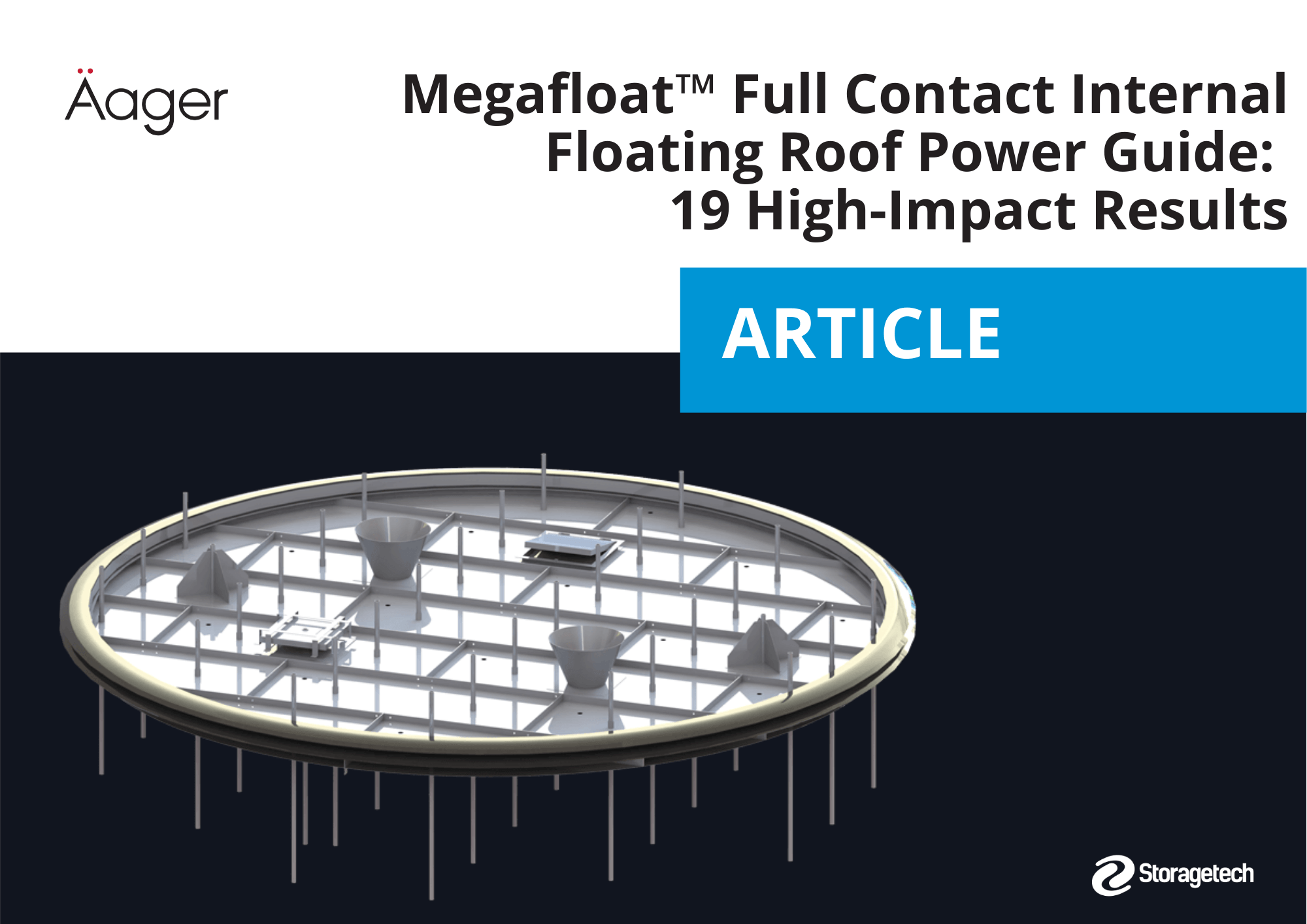

2) Full-contact internal floating roof

A full-contact design aims to minimize vapor space even further by keeping the deck closely in contact with the liquid surface (depending on design). This may improve vapor control, but it can be more sensitive to product compatibility, surface contaminants, and installation quality.

How to decide:

-

If you need stronger vapor control, a full-contact style may be preferred.

-

If you need ruggedness and simpler construction, a pontoon style can be effective.

-

If you expect sludge, wax, or debris, you must evaluate how the deck will behave over time. A poor match leads to stuck movement, seal damage, and costly downtime.

Aluminum vs. steel materials

Many internal floating roof systems are aluminum because it is lightweight and corrosion resistant in many tank environments. Lightweight matters because it improves buoyancy margins and reduces stress on accessories.

Steel (carbon steel or stainless steel, depending on service) can be used when:

-

The stored product and vapor space conditions demand it

-

The project specifications require particular materials

-

Mechanical robustness is prioritized over weight

-

Fire or temperature considerations push the selection (site rules vary)

Material selection should be based on:

-

Stored liquid properties

-

Vapor space chemistry (including potential corrosives)

-

Tank internal coating system (if any)

-

Compatibility with seals and gaskets

-

Local experience and inspection access

Typical accessories you should plan for

A complete internal floating roof package is not just the deck. It typically includes:

-

Primary rim seal (the first sealing barrier)

-

Secondary rim seal (extra sealing for improved control)

-

Deck legs (to support the roof at low liquid levels)

-

Gauge pole / well (for manual gauging, if required)

-

Support columns interface (for fixed roof columns, if present)

-

Anti-rotation devices (to prevent deck spinning)

-

Vents and bleeder vents (to manage trapped vapors)

-

Drains or liquid traps (depending on design and site practice)

-

Access and maintenance hardware (bolting, hatches, etc.)

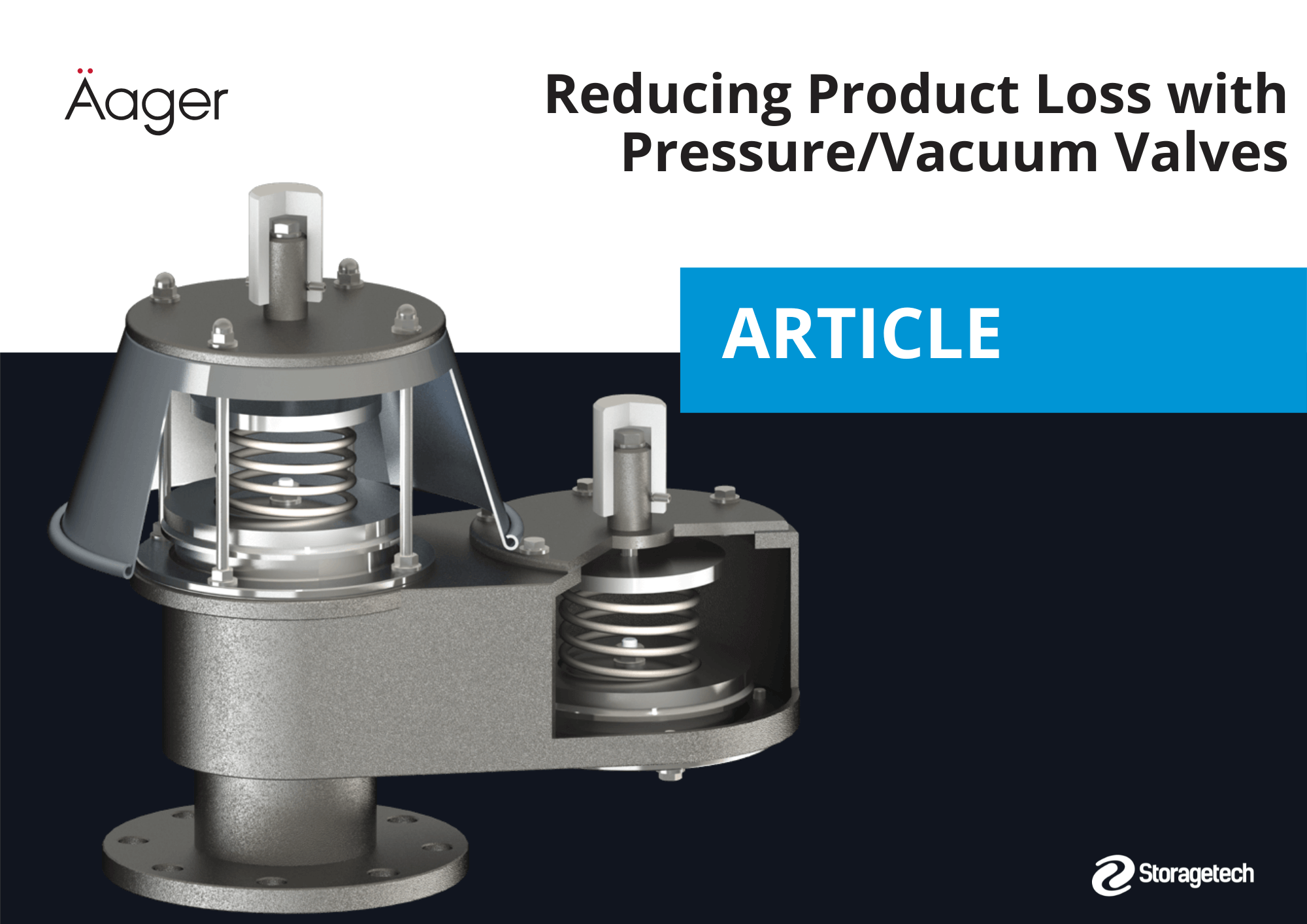

Seal system overview (why seals matter so much)

Most performance wins from an internal floating roof come from seals. Even a strong deck cannot help much if the rim seal is poorly designed or poorly installed.

A practical seal approach often includes:

-

Primary seal: The main vapor barrier at the rim.

-

Secondary seal: Backup barrier that improves tightness and helps reduce leakage.

In real projects, seal selection is where experience matters. The best-looking drawings won’t help if the seal material is not compatible with the stored product or if the rim geometry is not right.

3. Performance, Safety, and Compliance

An internal floating roof is usually justified on performance, safety, and compliance. These three topics overlap, but they are not identical. Good projects treat all three seriously.

Vapor loss and emissions: how reductions happen

Evaporation losses generally come from:

-

The vapor space above the product

-

The tank “breathing” due to temperature and pressure changes

-

Rim seal gaps and fitting losses

An internal floating roof reduces losses by:

-

Reducing the effective vapor space

-

Limiting liquid surface exposure to air/vapor circulation

-

Sealing the rim area where vapor leakage can occur

However, an internal floating roof is not “set and forget.” If seals degrade, if fittings leak, or if the deck is misaligned, performance drops quickly. That’s why inspection and maintenance are part of the value story.

Safety fundamentals you must respect

Safety with an internal floating roof is mostly about controlling risk factors that show up over years of operation, not on day one.

Key safety points:

-

Static electricity control: Projects often require bonding/grounding provisions and anti-static practices. Static risk is real during filling and emptying.

-

Vapor management: Trapped vapors under the deck must be handled correctly. Poor venting can lead to unexpected pressure pockets.

-

Drainage behavior: Rainwater is not inside a fixed roof tank, but condensation and product splashing still happen. You need a design that doesn’t trap liquids where they shouldn’t be.

-

Mechanical integrity: Deck legs, fittings, and seal components must survive repeated cycles without loosening or tearing.

If your tank has internal columns, special attention is needed. Column sleeves, wipers, and clearance control can make or break the long-term reliability of the internal floating roof.

Standards and typical specifications

Project specs for an internal floating roof often reference industry norms and local regulations. In practice, the governing standard depends on the tank type, jurisdiction, and owner requirements.

Common themes you’ll see in specifications:

-

Minimum buoyancy and compartment integrity requirements

-

Deflection limits and deck stability expectations

-

Primary and secondary seal requirements

-

Material certification and traceability (where required)

-

Workmanship, testing, and inspection criteria

-

Installation tolerances and tank roundness checks

Always treat compliance as project-specific. An internal floating roof may support compliance goals, but it must be correctly specified, installed, and maintained to deliver defensible results.

Inspection and maintenance (what good looks like)

A practical inspection program for an internal floating roof typically focuses on:

-

Seal condition: cracking, hardening, tears, uneven contact

-

Deck alignment: signs of binding, rubbing, or tilt

-

Fittings: gauge wells, vents, penetrations, and fasteners

-

Evidence of product pooling where it shouldn’t be

-

Corrosion or coating breakdown (if coated)

-

Hardware tightness and wear

A simple rule helps: if you can see daylight through a rim seal path, vapors can move too. That’s not a technical measurement, but it’s often a strong early warning sign.

4. Selection, Sizing, and Lifecycle Value

Choosing the right internal floating roof is more about fit-for-service engineering than choosing a catalog item. The best designs match the tank geometry, product, and operations style.

Decision checklist (use this before you finalize)

Use this checklist to select an internal floating roof that performs in real life:

-

Tank type and geometry

-

Diameter and height

-

Fixed roof style and internal obstructions (columns, nozzles)

-

Roundness and shell tolerances (especially for seal performance)

-

Stored liquid

-

Vapor pressure and volatility

-

Compatibility with seal materials

-

Potential for sludge, wax, solids, or polymer formation

-

Operations

-

Fill/empty frequency (cycling matters)

-

Typical operating level range

-

Presence of mixing, recirculation, or agitation

-

Performance requirements

-

Emissions or product loss target (if defined)

-

Need for primary + secondary seals

-

Any special requirements for fittings and penetrations

-

Inspection and maintenance access

-

Manways and roof access

-

Internal inspection strategy and intervals

-

Spare parts availability for the internal floating roof seals and fittings

Common pitfalls (and how to avoid them)

Most internal floating roof problems come from predictable causes:

-

Wrong seal material for the product: seals swell, shrink, crack, or harden.

-

Poor tank roundness: seals can’t maintain contact, so leakage rises.

-

Weak installation controls: small alignment issues become big wear issues.

-

Ignoring columns and nozzles: clearance and sleeves are not “minor details.”

-

No clear maintenance plan: seals wear out; pretending they don’t is costly.

If you want a simple takeaway: an internal floating roof works best when you treat it like critical rotating equipment—planned inspection, planned spares, and clear operating discipline.

Installation best practices that prevent headaches

Good installation of an internal floating roof typically includes:

-

Pre-install checks on tank geometry and internals

-

Cleanliness control (debris damages seals)

-

Fit-up verification for rim seal compression and contact

-

Functional checks for free movement across the full level range

-

Verification of fittings, vents, and gauge well integrity

-

Documentation: as-built checks, torque logs, and inspection notes

You don’t want surprises after commissioning. A clean, controlled installation is often the difference between “it floats” and “it performs.”

Total cost of ownership: how the value shows up

The lifecycle value of an internal floating roof comes from:

-

Reduced product loss (the obvious one)

-

Lower odor and emissions management burden (often important)

-

Improved product quality in some services

-

Potential reductions in corrosion drivers (service-dependent)

-

Improved operational confidence when the tank is frequently cycled

A realistic approach is to calculate:

-

Product saved per year (based on volatility and operating profile)

-

Maintenance cost per cycle (planned seal replacement, inspection)

-

Downtime risk and contingency costs

A properly selected internal floating roof is not just a compliance item. It is a performance asset—when you manage it like one.

FAQs

1) What is an internal floating roof, in simple terms?

An internal floating roof is a floating deck installed inside a fixed-roof tank. It sits on the liquid surface and moves with the liquid level to reduce evaporation and vapor space.

2) Does an internal floating roof work in every tank?

No. An internal floating roof must match the tank geometry and the stored product. Tanks with heavy sludge, solids, or unusual internals may need special designs or a different solution.

3) What matters more: the deck or the seals?

In many cases, seals matter more. The internal floating roof deck provides the floating platform, but seal performance often drives real vapor loss reduction.

4) Do I always need both primary and secondary seals?

Not always, but many projects prefer both for stronger control. A primary + secondary seal system often improves the performance of an internal floating roof, especially when emissions control is a key goal.

5) What are the most common maintenance issues?

Seal wear, fitting leaks, and deck misalignment are common. Regular inspection and planned spare parts help keep the internal floating roof performing over time.

6) Which standards should I reference?

That depends on the project and jurisdiction. Tank design and roof system requirements are typically defined by the owner’s specification and applicable tank standards. Always align the internal floating roof scope with the governing project documents.

7) Can you share a credible external reference to learn more?

Yes. A practical starting point is the U.S. EPA’s information on air emissions from storage tanks and controls (useful context for why vapor control matters).