Overview

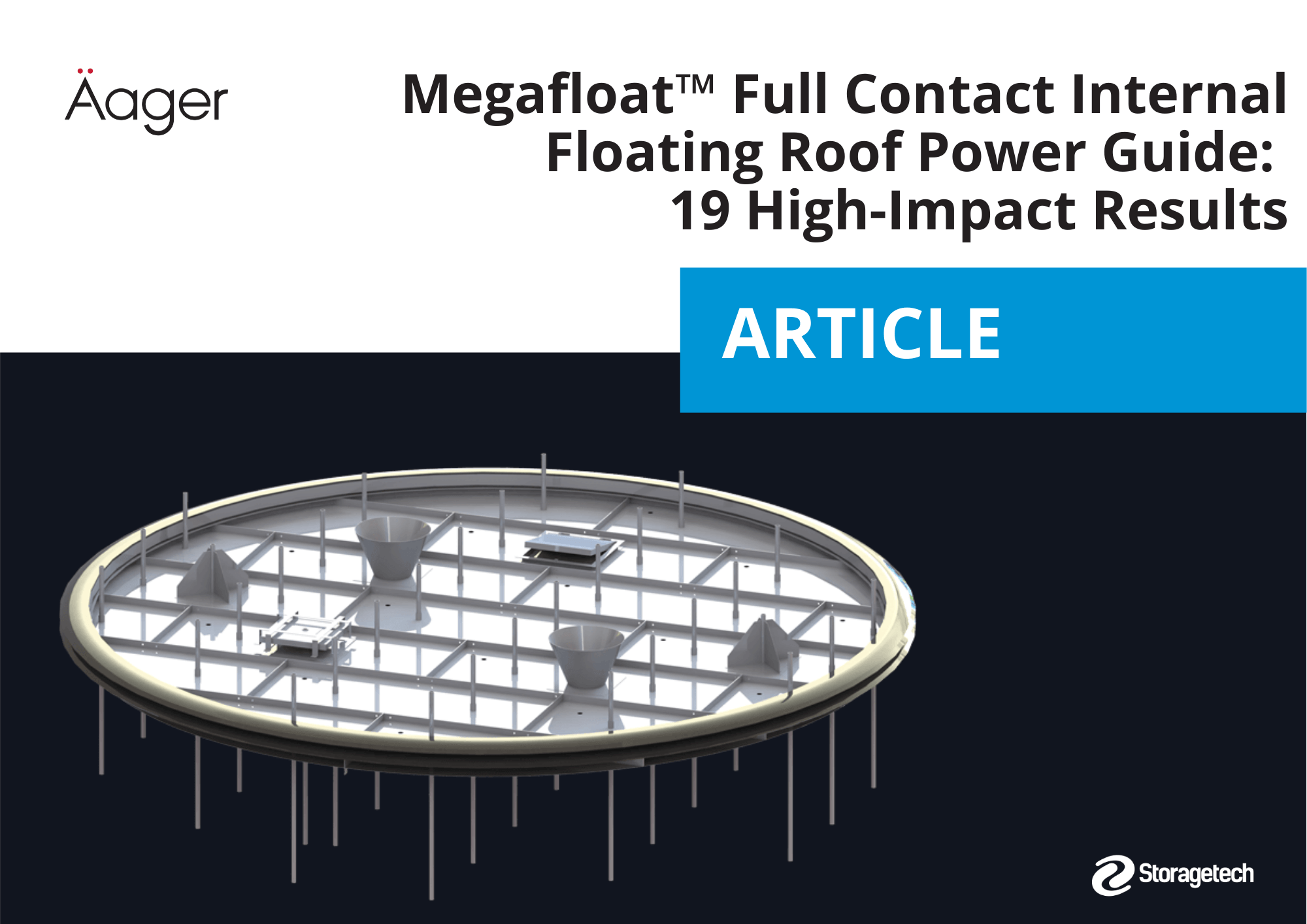

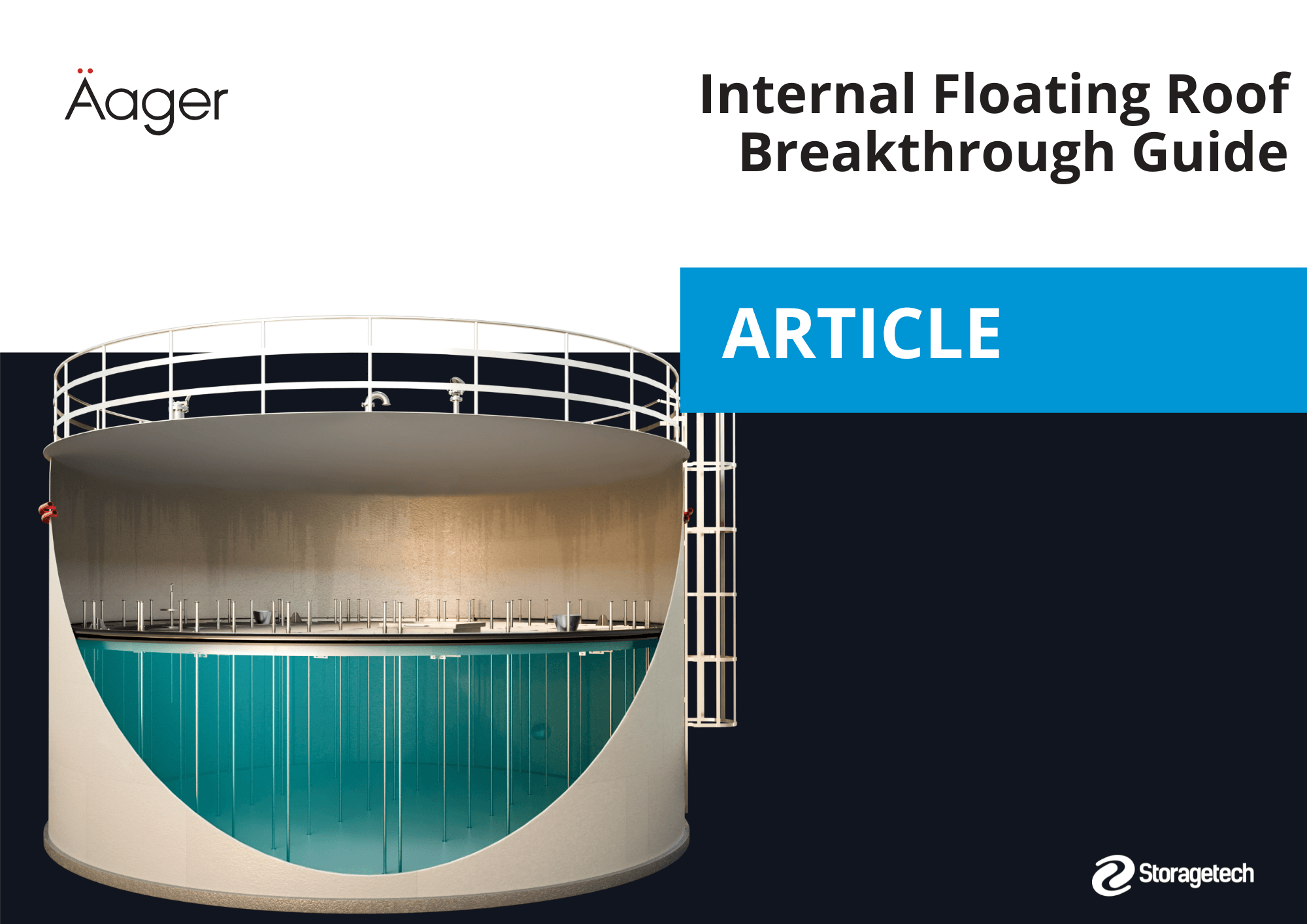

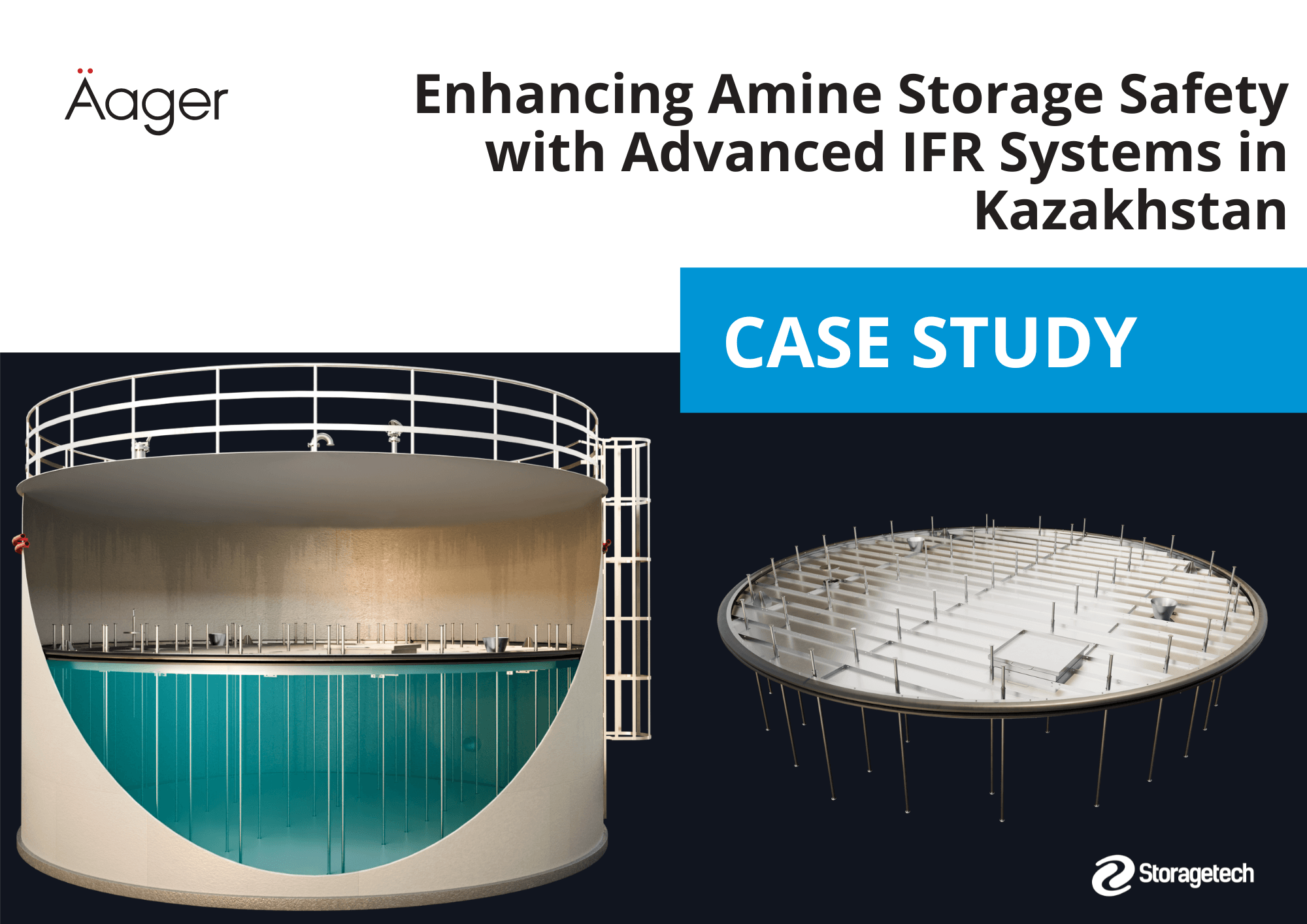

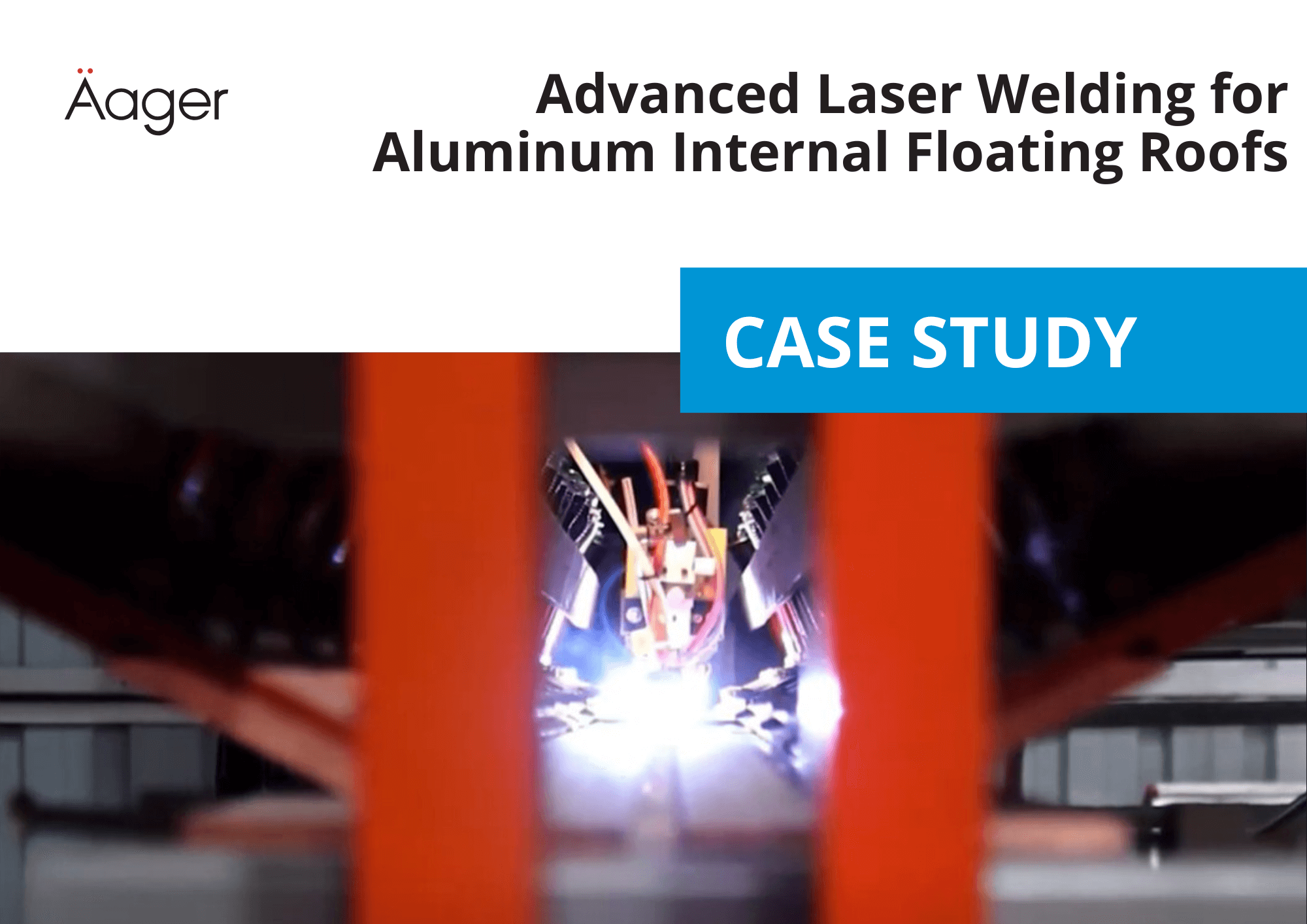

ERGIL’s use of laser welding technology represents a significant leap forward in the production of Aluminum Internal Floating Roofs (IFRs), particularly our Mega Float type roofs. Unlike traditional welding methods, laser welding offers unparalleled precision, durability, and efficiency, ensuring products that meet the highest industry standards for safety and performance.

The Challenge

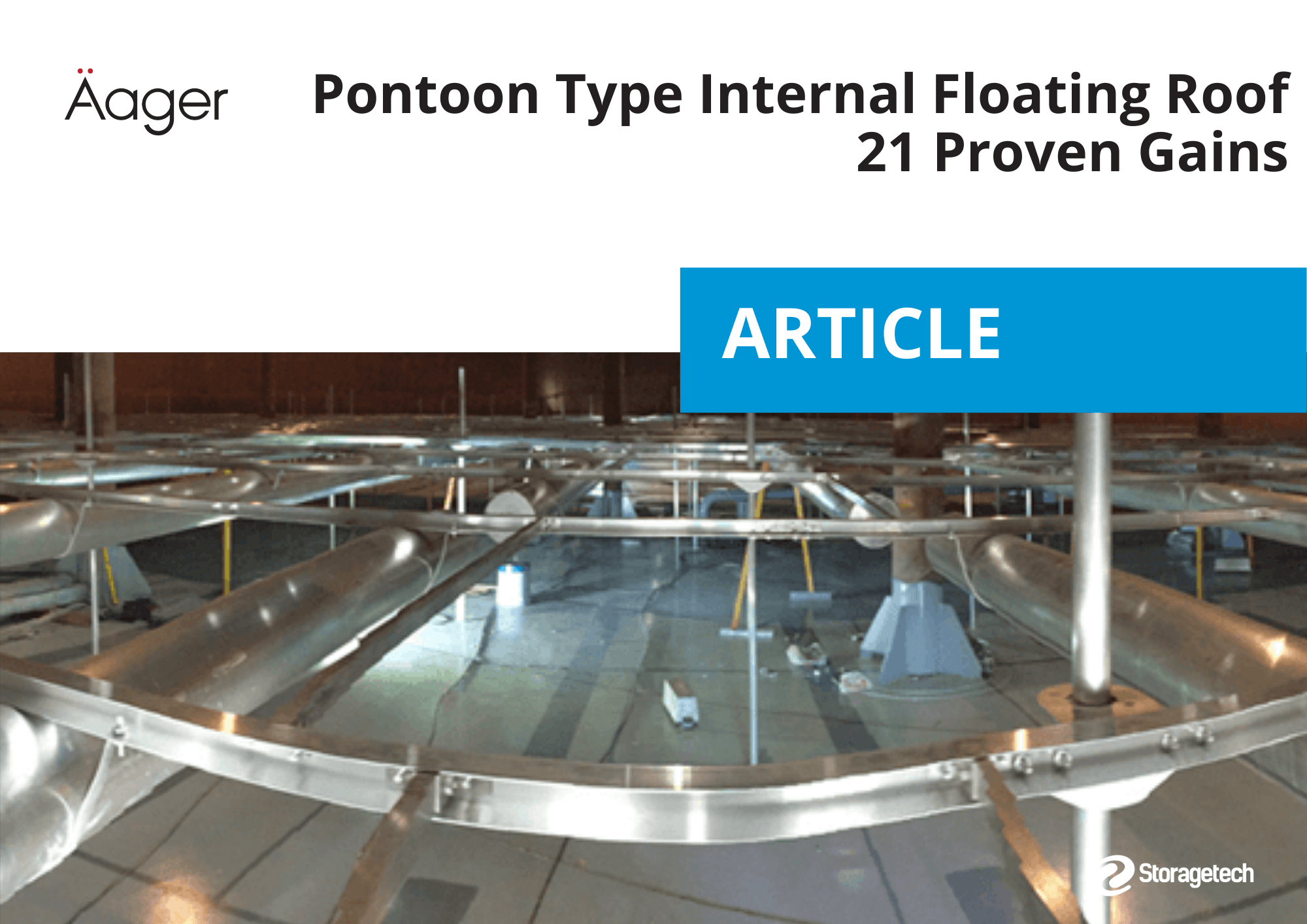

Aluminum IFRs are critical in reducing evaporation losses and minimizing emissions of volatile organic compounds (VOCs) in storage tanks. The manufacturing process requires precision to maintain the lightweight nature of aluminum while ensuring robust structural integrity. Traditional welding techniques often lead to issues such as material distortion, weld inconsistencies, and increased risk of leaks and corrosion.

Our Solution

ERGIL integrated advanced laser welding technology into the production of its Mega Float Aluminum internal floating roofs to address these challenges. Laser welding offers:

- Seamless Precision: Tight, consistent welds that minimize material waste and ensure secure joints.

- Reduced Distortion: A minimal heat-affected zone preserves the structural integrity of the aluminum.

- Increased Durability: High-strength welds withstand harsh environmental and operational conditions.

- Efficiency: Faster processing times and reduced production costs.

Application in Mega Float Roofs

The Mega Float type IFRs benefit significantly from laser welding. The process creates seamless, corrosion-resistant welds that provide enhanced durability and leak protection. These features are vital in safeguarding against VOC emissions, ensuring compliance with stringent environmental standards.

Key Benefits

- Improved Durability: Welds resist corrosion and extend product life even under extreme conditions.

- Enhanced Safety: Reduced risk of leaks ensures safe operation.

- Sustainability: Minimizes material waste and supports environmental compliance.

- Cost Efficiency: Faster production times lower overall manufacturing costs.

Conclusion

ERGIL’s adoption of laser welding for Aluminum IFRs highlights our commitment to innovation and quality. The seamless integration of advanced technology ensures that our Mega Float roofs deliver unmatched performance and longevity, making them the ideal choice for storage solutions that prioritize safety, efficiency, and environmental responsibility.

Results

Since implementing laser welding, ERGIL has:

- Reduced production times by 30%.

- Enhanced product reliability, with a significant decrease in maintenance requirements.

- Met and exceeded industry standards for VOC containment.

Contact Us

To learn more about ERGIL’s laser-welded Aluminum Internal Floating Roofs and how they can optimize your operations, visit https://ergil.com/