Flame arresters are crucial safety devices that prevent the propagation of flames and explosions in various industrial processes. Their design, functionality, and application can significantly impact the safety and efficiency of operations. This comprehensive guide delves into detailed case studies of flame arrester applications across different industries, providing insights into their importance, implementation, and benefits.

Case Study 1: Chemical Processing Industry

Overview

In the chemical processing industry, handling volatile organic compounds (VOCs) and other flammable substances is routine. Flame arresters play a pivotal role in ensuring safety by preventing the spread of flames through piping systems and storage tanks.

Scenario: Protection of Chemical Storage Tanks

Objective: To prevent external flames from igniting volatile organic compounds stored in large chemical tanks. Implementation: End-of-line flame arresters were installed on vent lines of storage tanks containing VOCs. Details:

- Material: Stainless steel for corrosion resistance.

- Design: Crimped metal ribbons to cool and quench the flame.

- Standards: Compliance with ISO 16852 and NFPA 69. Outcome: Successfully prevented flames from entering the tanks during a fire incident nearby, showcasing the importance of flame arresters in protecting volatile chemicals.

Scenario: Safety in Process Piping

Objective: To stop flame propagation in process piping systems transporting flammable gases. Implementation: Inline flame arresters were strategically placed in gas pipelines. Details:

- Material: Nickel-alloy for high-temperature resistance.

- Design: Mesh screens for efficient flame quenching.

- Standards: Adherence to ASME and ATEX standards. Outcome: Flame arresters effectively halted flame spread during a gas leak, preventing a potential explosion.

Case Study 2: Oil and Gas Industry

Overview

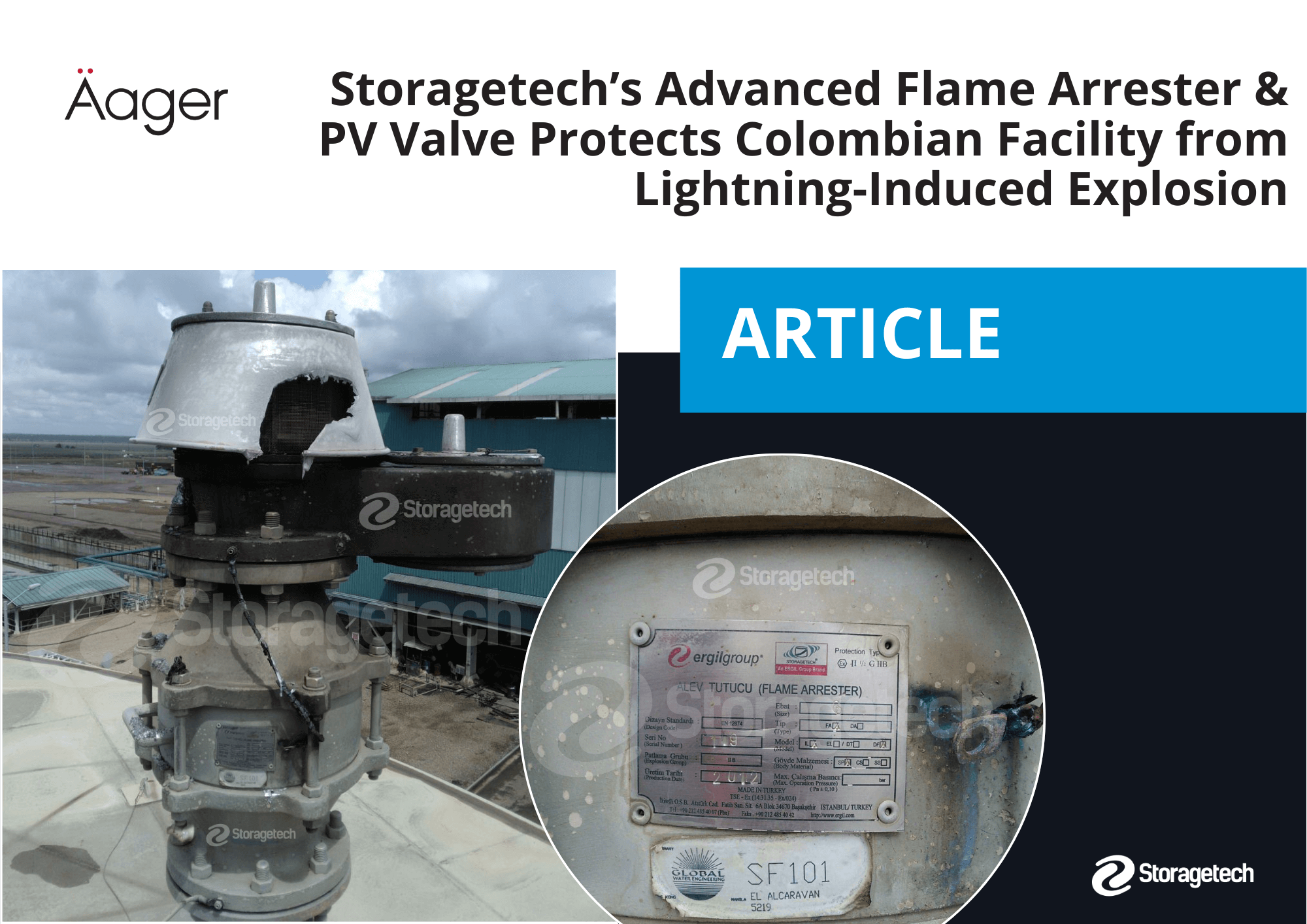

The oil and gas industry deals with highly flammable hydrocarbons, necessitating stringent safety measures. Flame arresters are vital in preventing explosions and ensuring the safe operation of storage tanks and pipelines.

Scenario: Crude Oil Storage Safety

Objective: To protect crude oil storage tanks from external ignition sources. Implementation: End-of-line flame arresters were installed on tank vents. Details:

- Material: Marine-grade stainless steel for offshore installations.

- Design: Double-layered crimped ribbons for enhanced safety.

- Standards: API 2000 compliance. Outcome: Prevented external flames from entering storage tanks during a lightning storm, safeguarding the stored crude oil.

Scenario: Flare System Protection

Objective: To stop backflow of flames in flare stacks used for burning off excess hydrocarbons. Implementation: Inline flame arresters were installed in flare stacks. Details:

- Material: High-grade stainless steel to withstand corrosive gases.

- Design: Multi-layer mesh screens for effective flame arresting.

- Standards: Compliance with BS 7244 and API 537. Outcome: Successfully prevented backflow of flames, ensuring safe flare operation during routine maintenance.

Case Study 3: Pharmaceutical Industry

Overview

The pharmaceutical industry uses various flammable solvents and gases in the production of medicines and APIs. Flame arresters are essential for preventing fires and explosions in these processes.

Scenario: Solvent Recovery System Safety

Objective: To prevent flames from entering solvent recovery systems. Implementation: End-of-line flame arresters were installed on vent lines of solvent recovery units. Details:

- Material: Stainless steel for non-reactivity.

- Design: Fine mesh screens for high efficiency.

- Standards: Compliance with ATEX and cGMP standards. Outcome: Successfully prevented flames from igniting solvents during a fire drill, ensuring safe solvent recovery operations.

Scenario: Reactor Vent Safety

Objective: To stop flames from entering chemical reactors during exothermic reactions. Implementation: Inline flame arresters were installed on reactor vents. Details:

- Material: Inconel for high-temperature resistance.

- Design: Dense mesh structure for efficient flame quenching.

- Standards: Adherence to ASME and ISO standards. Outcome: Flame arresters effectively stopped flame entry during an unexpected pressure surge, preventing reactor explosion.

Case Study 4: Water Treatment Facilities

Overview

Water treatment facilities generate flammable gases like methane during wastewater treatment. Flame arresters ensure these gases are handled safely to prevent explosions.

Scenario: Biogas System Safety

Objective: To prevent flames from traveling back into biogas storage tanks. Implementation: End-of-line flame arresters were installed on biogas vent lines. Details:

- Material: Corrosion-resistant stainless steel.

- Design: Crimped ribbons for effective flame arresting.

- Standards: Compliance with EN 12874 and ISO 16852. Outcome: Prevented flames from entering biogas tanks during a routine maintenance operation, ensuring safe biogas handling.

Scenario: Gas Storage and Distribution Safety

Objective: To stop flame propagation in gas storage and distribution lines. Implementation: Inline flame arresters were installed in gas pipelines. Details:

- Material: Marine-grade stainless steel for outdoor installations.

- Design: Multi-layer mesh screens for high efficiency.

- Standards: Adherence to ATEX and NFPA standards. Outcome: Successfully prevented flames from traveling through pipelines during a gas leak, ensuring safe gas distribution.

Case Study 5: Food and Beverage Industry

Overview

The food and beverage industry involves processes that produce flammable gases, such as ethanol vapor during fermentation and distillation. Flame arresters ensure these processes are safe from ignition sources.

Scenario: Fermentation Process Safety

Objective: To prevent external flames from igniting ethanol vapors during fermentation. Implementation: End-of-line flame arresters were installed on fermentation tanks. Details:

- Material: Food-grade stainless steel.

- Design: Fine mesh screens for efficient flame quenching.

- Standards: Compliance with NFPA 30 and ATEX. Outcome: Prevented external flames from entering fermentation tanks during a fire drill, ensuring safe fermentation operations.

Scenario: Distillation Column Safety

Objective: To stop flames from entering distillation columns during the production of spirits. Implementation: Inline flame arresters were installed on distillation vents. Details:

- Material: High-grade stainless steel for non-reactivity.

- Design: Multi-layer mesh screens for effective flame arresting.

- Standards: Adherence to ASME and ISO standards. Outcome: Successfully stopped flames from entering distillation columns during an unexpected pressure surge, preventing potential explosions.

Flame arresters are indispensable safety devices across various industries, providing critical protection against the propagation of flames and explosions. These case studies highlight the importance of flame arresters in different sectors, showcasing their effectiveness in enhancing safety and ensuring smooth operations. ERGIL, with its extensive experience and expertise, offers a wide range of high-quality flame arresters designed to meet the diverse needs of industries worldwide. Whether in chemical processing, oil and gas, pharmaceuticals, water treatment, or food and beverage, flame arresters play a vital role in ensuring safe and efficient operations.