Deflagration and Detonation:

A Comprehensive Analysis for Industrial Safety

In the realm of industrial safety, particularly in environments where flammable gases or vapors are present, understanding the phenomena of deflagration and detonation is crucial. These two types of combustion processes represent significant hazards in various industries, including oil and gas, chemical processing, and manufacturing. This analysis aims to provide a detailed explanation of deflagration and detonation, their characteristics, differences, and implications for safety equipment design, particularly flame arresters.

Characteristics and Behavior

Industrial Relevance

| Deflagration | Detonation |

|---|---|

| Deflagrations are more common in industrial settings than detonations. They can occur in: | While less common than deflagrations, detonations pose extreme hazards in industrial settings. They are particularly concerning in: |

| Storage tanks | Large-scale storage facilities |

| Process vessels | Processes involving highly reactive gases |

| Pipelines | Long pipelines |

| Enclosed spaces with flammable atmospheres | |

| While less severe than detonations, deflagrations can still cause significant damage due to pressure effects and thermal exposure. | The potential for a deflagration to transition to a detonation (known as Deflagration to Detonation Transition or DDT) is a significant safety concern in many industrial processes. |

Influencing Factors

Comparing Deflagration and Detonation

Understanding the differences between deflagration and detonation is crucial for proper risk assessment and safety system design.

| Characteristic | Deflagration | Detonation |

|---|---|---|

| Flame Speed | Subsonic (<100 m/s) | Supersonic (1500-2000 m/s) |

| Pressure Rise | Moderate (<8 bar) | Extreme (>20 bar) |

| Reaction Zone | Thick | Very thin |

| Driving Mechanism | Heat transfer | Shock compression |

| Pressure Profile | Gradual rise | Sharp spike |

| Flame Front Structure | Smooth | Cellular structure |

| Risk of Occurrence | Higher | Lower, but more severe |

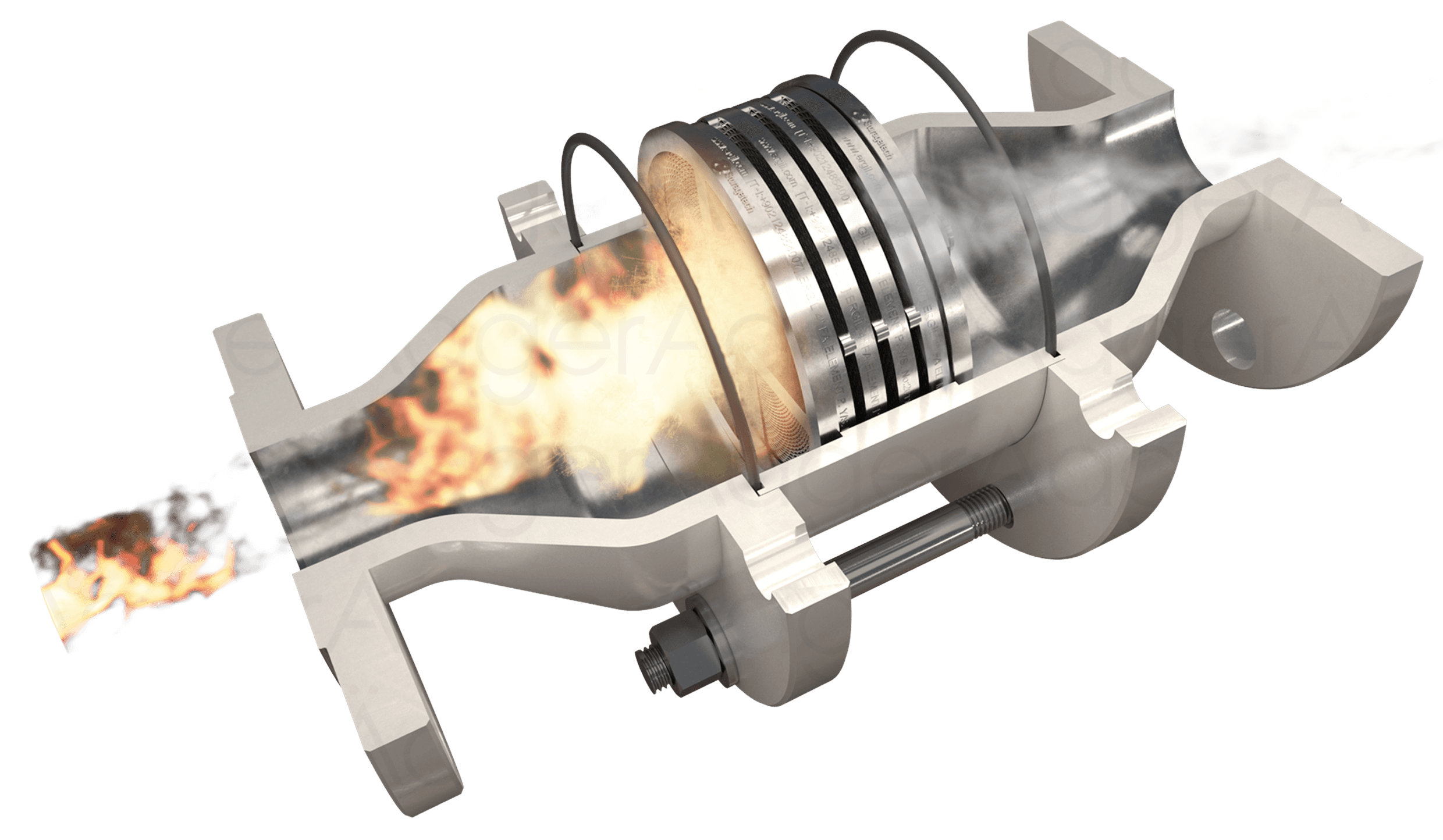

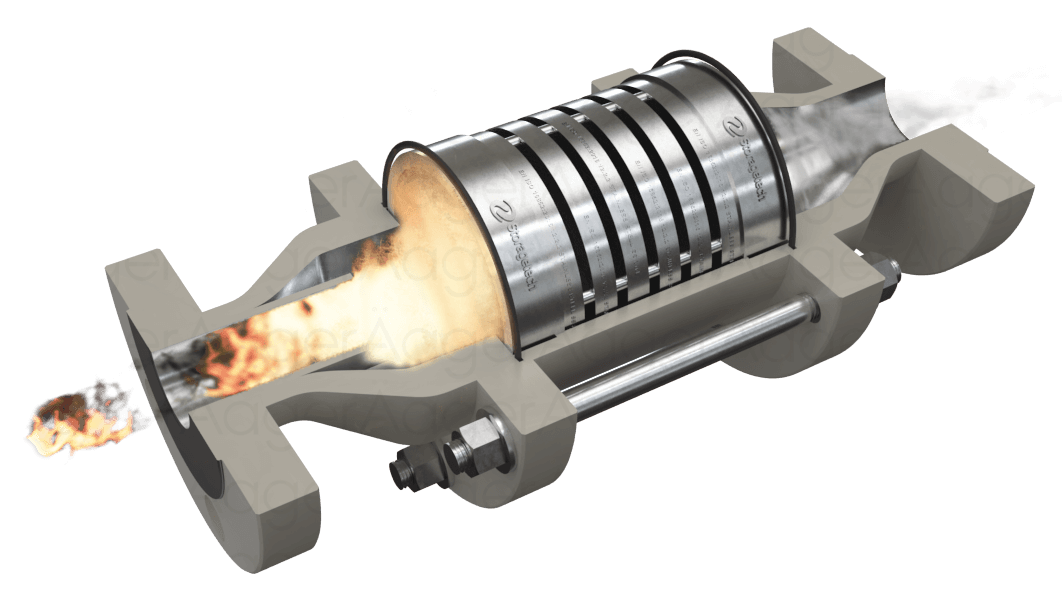

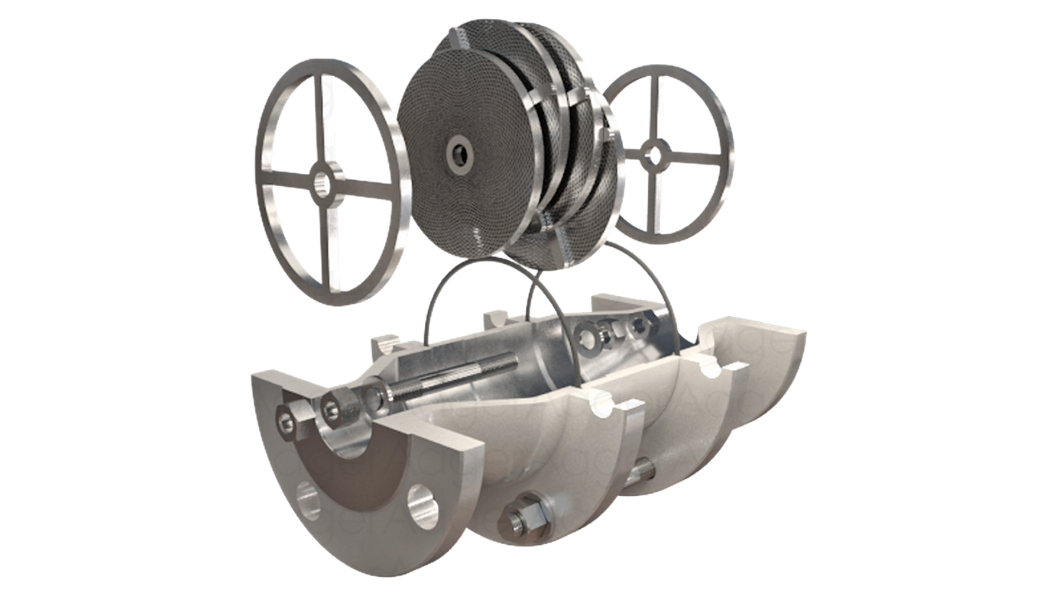

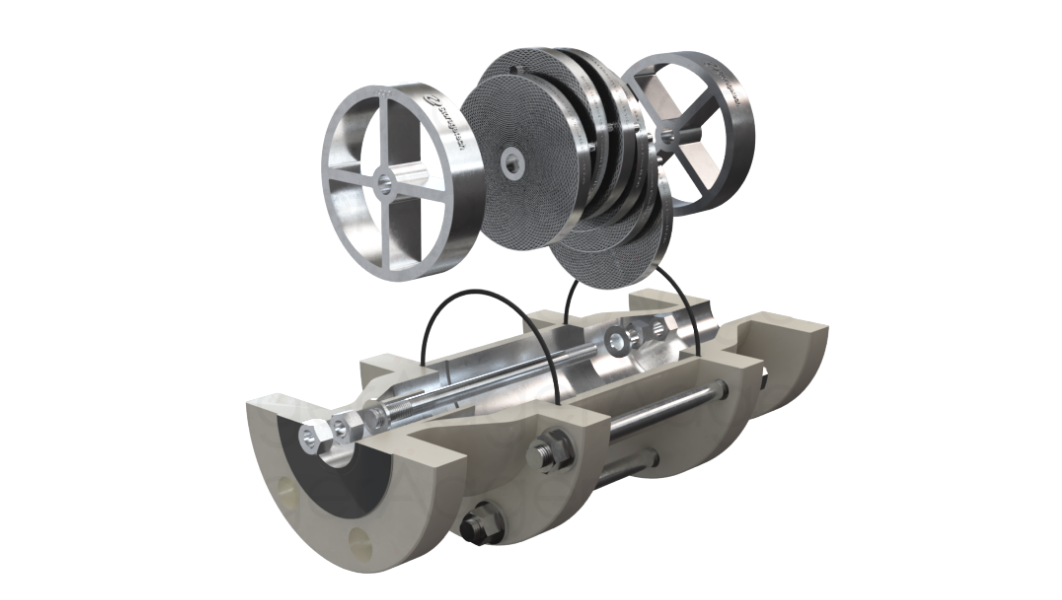

Flame Arrester Design Considerations

The distinct characteristics of deflagration and detonation have significant implications for the design of safety equipment, particularly flame arresters.

Testing

Flame arresters must undergo rigorous testing to ensure their effectiveness:

| Deflagration Testing | Detonation Testing |

|---|---|

| Involves igniting flammable mixtures at various concentrations | Requires specialized test rigs capable of generating stable detonations |

| Tests performed with and without pre-compression | Tests conducted at various pressures and with different gas mixtures |

| Multiple ignition locations to simulate worst-case scenarios | Arresters must demonstrate ability to quench high-speed flames and withstand pressure spikes |

Certification

Prevention and Mitigation Strategies

Understanding the fundamental differences between deflagration and detonation is crucial for designing effective safety systems in industrial environments. While deflagrations are more common, the potential for detonation, especially in confined spaces or long pipelines, must always be considered. Proper selection, installation, and maintenance of flame arresters, along with comprehensive safety protocols, are essential for mitigating these risks.

As technology advances, ongoing research continues to improve our understanding of these phenomena and enhance the effectiveness of safety equipment. Industries dealing with flammable gases and vapors must stay abreast of these developments to ensure the highest levels of safety in their operations.