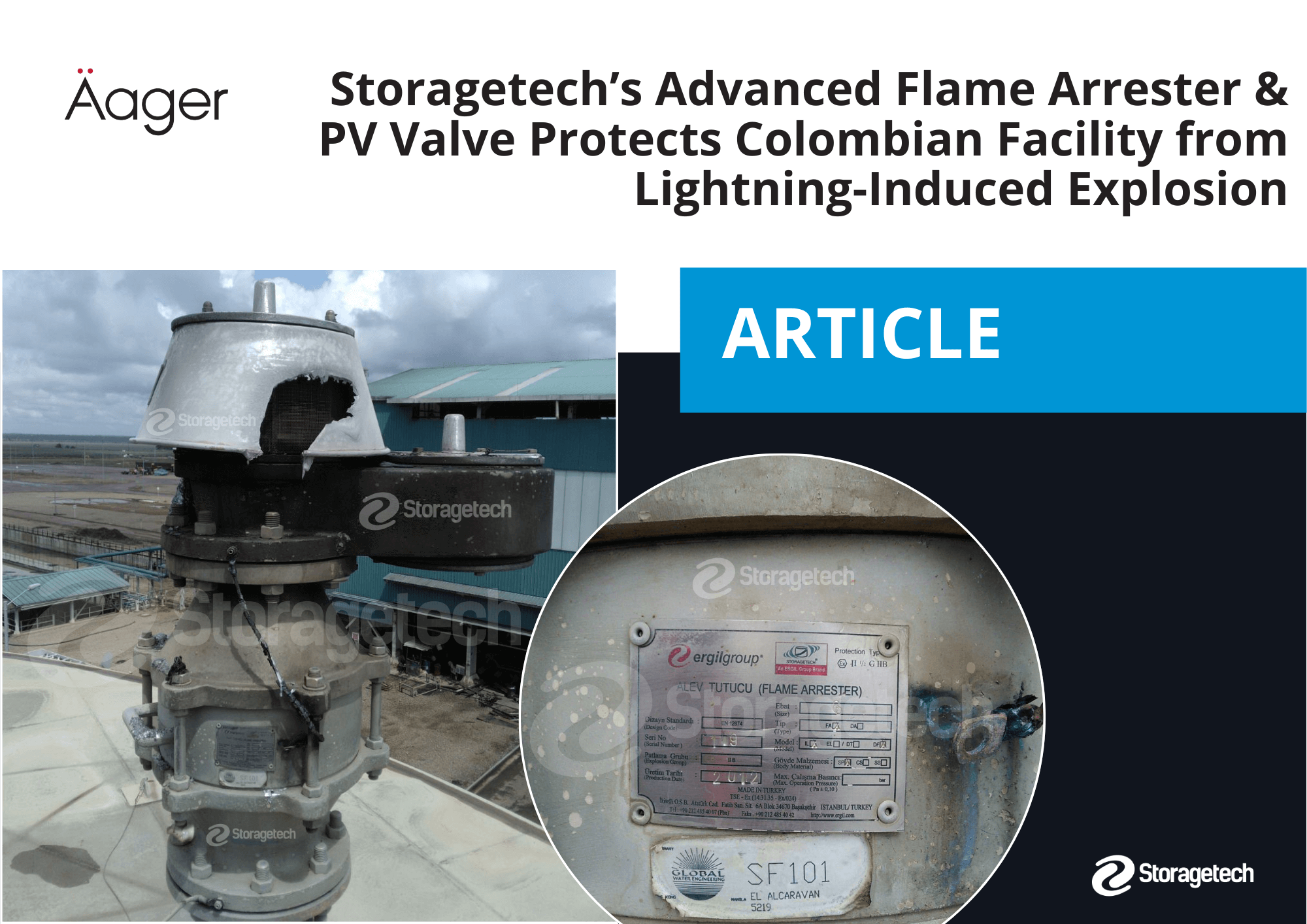

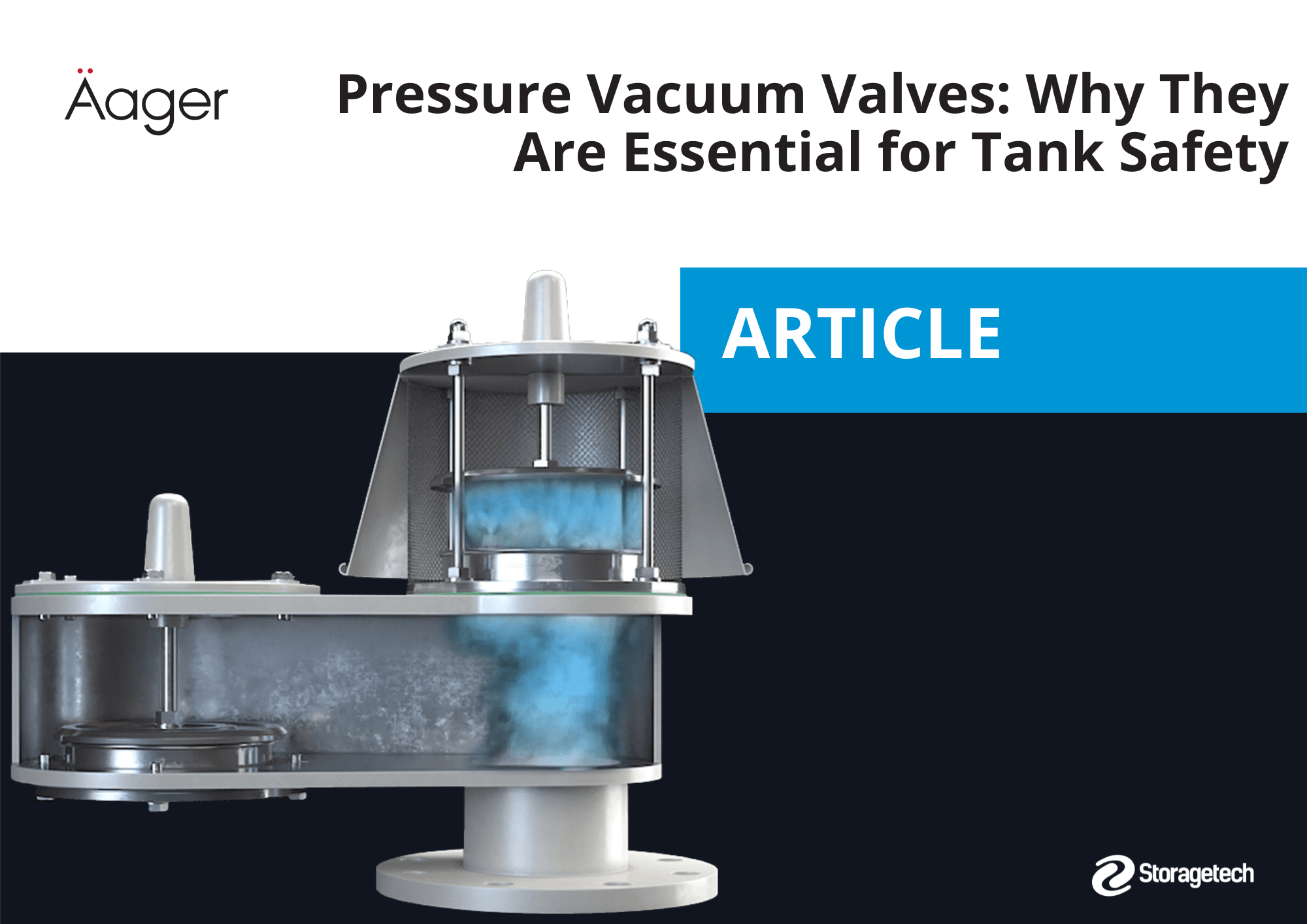

When it comes to handling volatile liquids or chemicals in storage tanks, safety is not something that can be taken lightly. Pressure Vacuum Valves (PV Valves)—often referred to as breather valves—play a pivotal role in maintaining the integrity of tanks used in industries such as oil and gas, petrochemicals, and pharmaceuticals. Below is an in-depth look at how these specialized valves function and why they are indispensable for modern tank safety.

What Exactly Are Pressure Vacuum Valves?

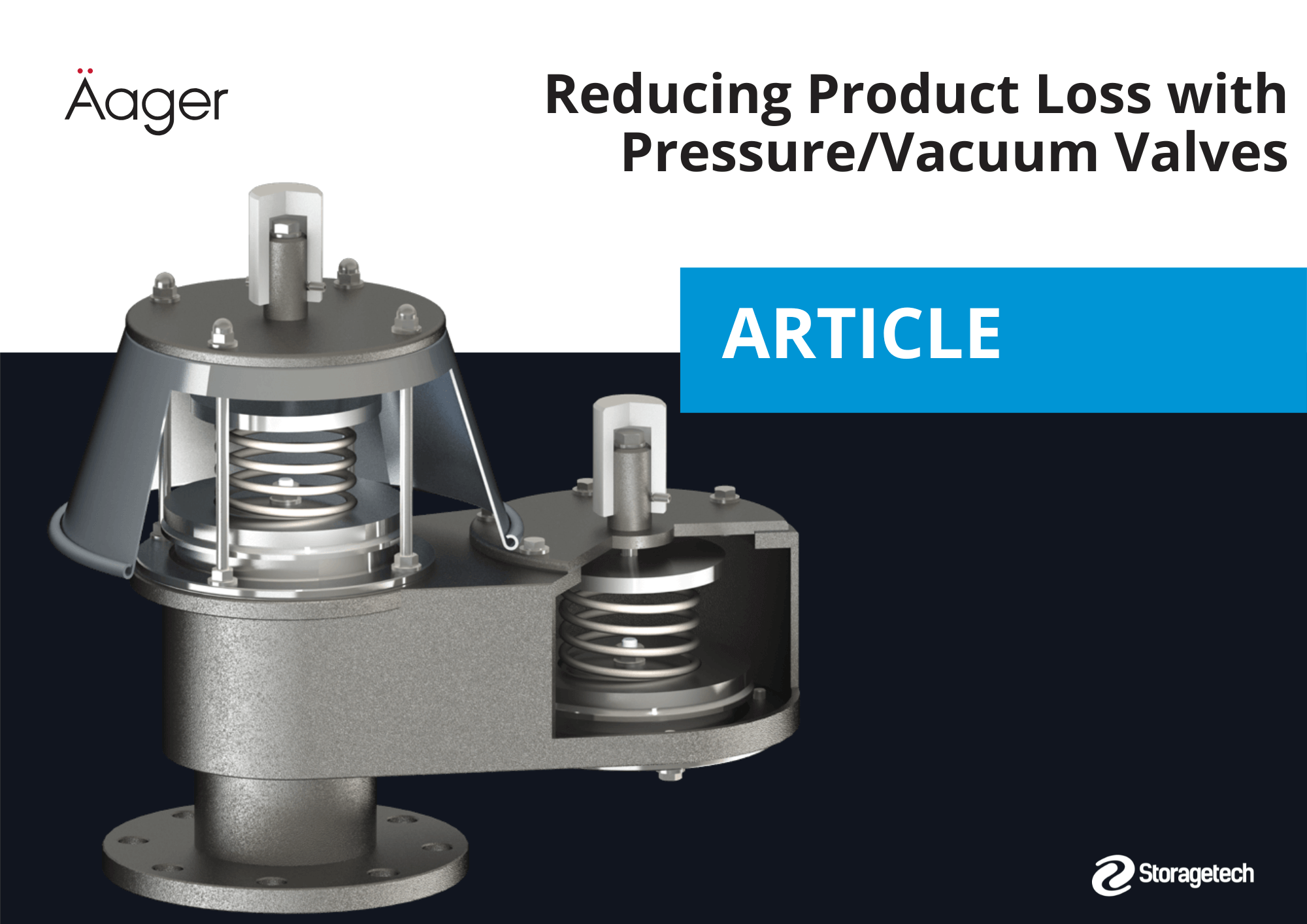

A Pressure Vacuum Valve is a type of venting device engineered to protect storage tanks from two extreme conditions: overpressure and excessive vacuum. Storage tanks routinely experience variations in internal pressure due to temperature fluctuations, product filling or withdrawal, and external environmental changes. If a tank’s internal pressure rises too high or falls too low, structural damage can occur—leading to leaks, ruptures, or even catastrophic failure.

Key Features of Pressure Vacuum Valves include:

- Set Points: Each valve has pre-determined pressure and vacuum settings at which it will open to allow air or vapor to flow in or out.

- Self-Closing Mechanism: When the internal pressure normalizes, the valve reseals automatically to minimize vapor loss or air ingress.

- In-Line or End-of-Line Configurations: These valves can be installed directly on the tank roof (end-of-line) or in piping systems (in-line), depending on operational needs.

Why Are They Critical for Tank Safety?

- Prevention of Structural Damage

Overpressure can lead to a bulging or burst tank, while a vacuum condition can cause the walls of the vessel to implode. By maintaining a balanced internal atmosphere, PV Valves ensure that tanks stay within safe pressure limits. - Product Loss Reduction

Tanks often store expensive or hazardous materials. Without adequate venting controls, vapor can escape, causing both economic loss and an environmental burden. PV Valves reduce unnecessary emissions and preserve valuable product. - Regulatory Compliance and Environmental Protection

Many regions have strict regulations for controlling emissions from storage facilities. Properly maintained PV Valves help facilities meet environmental standards by preventing volatile organic compounds (VOCs) from leaking into the atmosphere. - Operational Efficiency

Tanks that repeatedly experience pressure-related stress are more prone to wear and tear. By minimizing fluctuations, operators can avoid frequent maintenance issues and ensure a longer service life for their equipment.

Benefits Beyond Safety

Although tank protection remains the primary objective, PV Valves also offer a range of secondary advantages. They help in controlling odors by limiting vapor release to the environment, which is especially crucial for facilities located near populated areas. Moreover, they contribute to more stable product storage conditions—an important factor for substances sensitive to oxygen exposure or moisture ingress.

Best Practices for Selecting and Maintaining PV Valves

- Correct Sizing:

Conduct thorough calculations to determine the required venting capacity. A valve that is too small or too large for a given tank can lead to ineffective pressure control. - Material Compatibility:

The internal parts of the valve should resist corrosion or chemical degradation, especially if the stored product is highly reactive or acidic. - Routine Inspections:

Schedule regular checks for wear, corrosion, and proper set-point function. Even slight malfunctions can escalate quickly in high-risk environments. - Calibration and Testing:

Periodically calibrate the valves to verify that their pressure and vacuum set points remain accurate. Testing can be done in a controlled environment or with specialized on-site equipment. - Spare Parts and Documentation:

Maintain an inventory of critical spare components, and keep detailed maintenance records. This practice helps streamline repairs and ensures that any issues are promptly addressed.

Making Safety a Priority

In an age of increasing environmental awareness and tighter regulations, Pressure Vacuum Valves stand out as a key piece of equipment that goes beyond mere compliance. Their ability to safeguard tank integrity, preserve valuable products, and protect the environment makes them an indispensable tool in any facility handling volatile or hazardous materials. By selecting valves that match the specific operational demands of a plant and by following stringent maintenance protocols, operators can strike a balance between safety, cost efficiency, and regulatory obligations.

Mohammed HASSAN

Technical Coordinator