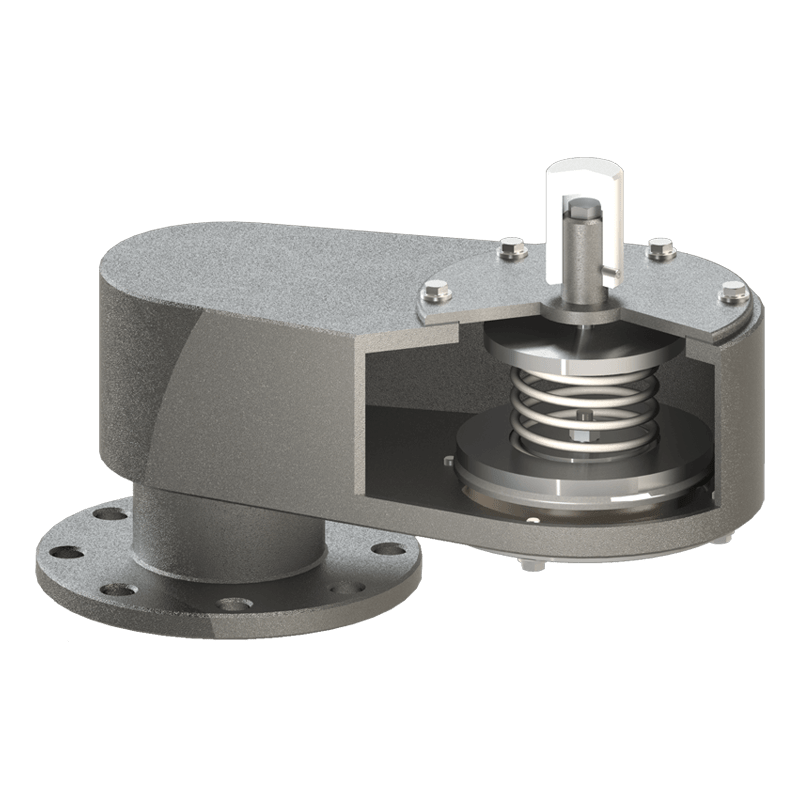

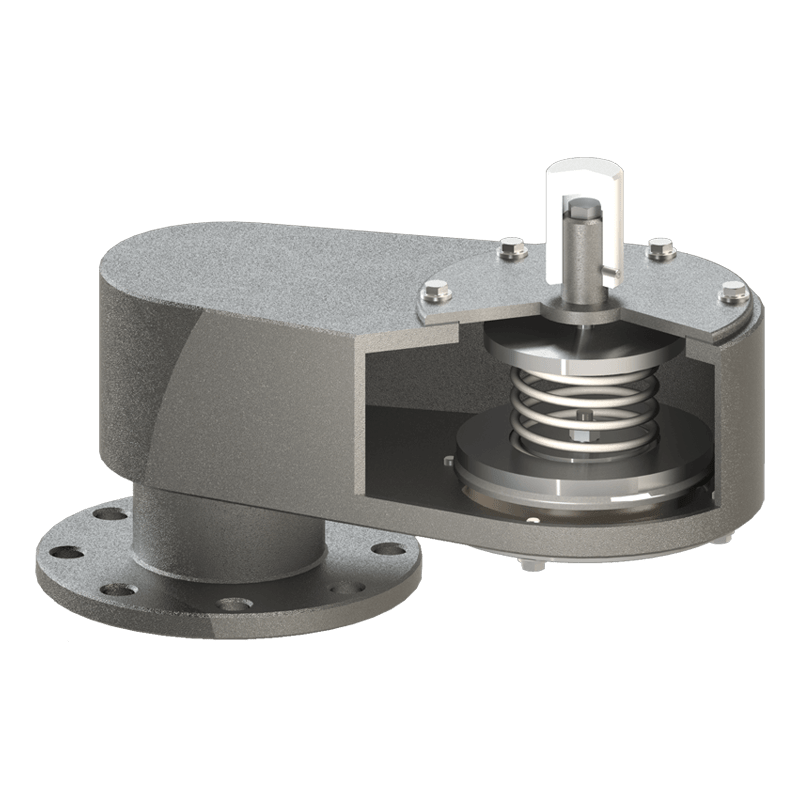

Model No: 193

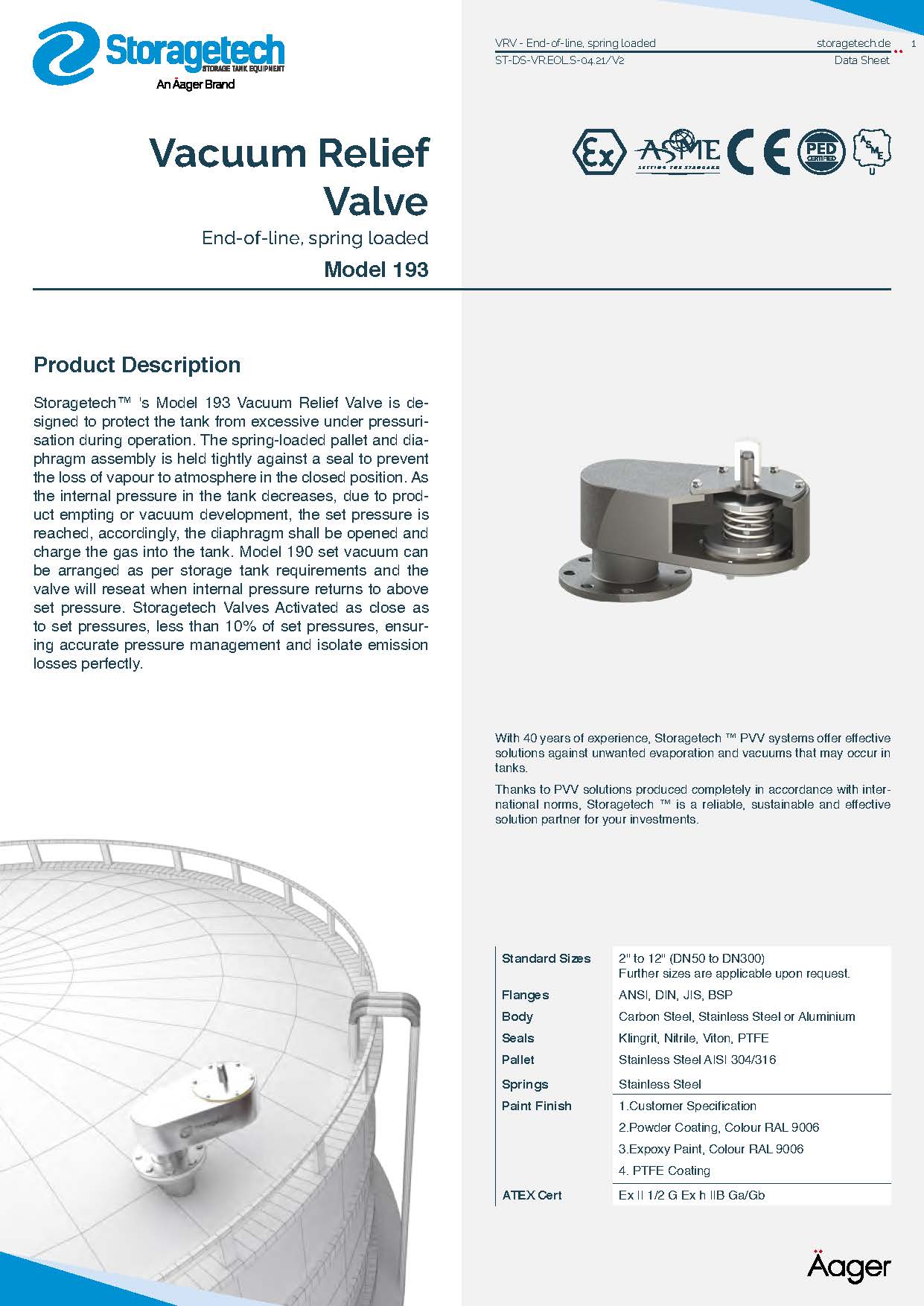

Storagetech’s Model 193 Vacuum Relief Valve ensures that the pressure in the bulk storage tank does not fall below the safe operating range needed to prevent implosion damage. It is fitted on a tank roof flange or pipe that connects to the vapour space of a storage tank.

In the closed position, the spring-loaded pallet and diaphragm assembly is held tightly against a seal to prevent the loss of vapour to the atmosphere. As the internal pressure in the tank reduces, due to emptying, the balance between the tank pressure and the external atmospheric pressure changes, and when the set pressure of the unit is reached, the diaphragm will open to admit air and rebalance the internal pressure. The opening set-point is selectable from a range between +61 mbar and +1000 mbar (+24 inch W.C. and 400 inch W.C.)

| Vacuum | Spring-loaded +61 mbar and +1000 mbar (+24 inch W.C. and 400 inch W.C.) |

| Ambient temp | -20°C to +60°C |

| Standard sizes | 2” to 12” 50 to 300mm |

| Flanges | API Class 150 RF, DIN PN16 |

| Body | Carbon steel, stainless steel, or aluminium |

| Seals | Nitrile, Teflon, and Klingrit |

| Pallet | Stainless steel AISI 304 |

| Springs | Stainless steel |

| Paint finish | 1-) Powder Coating, Colour RAL 9006 2-) Epoxy Paint, Colour RAL 9006 3-) Customer Specification |

| ATEX cert | Ex II 1/2 G c IIB |

The integrity of the seal is tested for leakage in accordance with API Standard 2521 – Use of Pressure-Vacuum Vent Valves for Atmospheric Loss.

The size of the vent should be calculated in accordance with API Standard 2000 (ISO 28300) – Venting Atmospheric and Low-Pressure Storage Tanks or other international standards.

Data sheet, Pressure Relief, Vacuum Relief, and Pressure-Vacuum Relief Valves

The vent will close when the tank returns to a positive pressure. A mesh filter screen over the air inlet port prevents the ingress of atmosphere-borne debris.

Several features are inherent in the valve design to ensure a smooth, positive and effective operation. The body is self-draining and drip rings prevent condensate from settling on seating surfaces. A diaphragm and seal manufactured from Teflon reduce the possibility of ice formation and sticky residues hindering the valve from opening, while the pallet assembly moves freely on guide posts.

Deflagration vs Detonation

Learn the key differences between deflagration and detonation.

Combustion Process

Explore the science behind combustion and its applications.

Explosion Groups

Discover the different types of explosions and our products.

Request a Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon