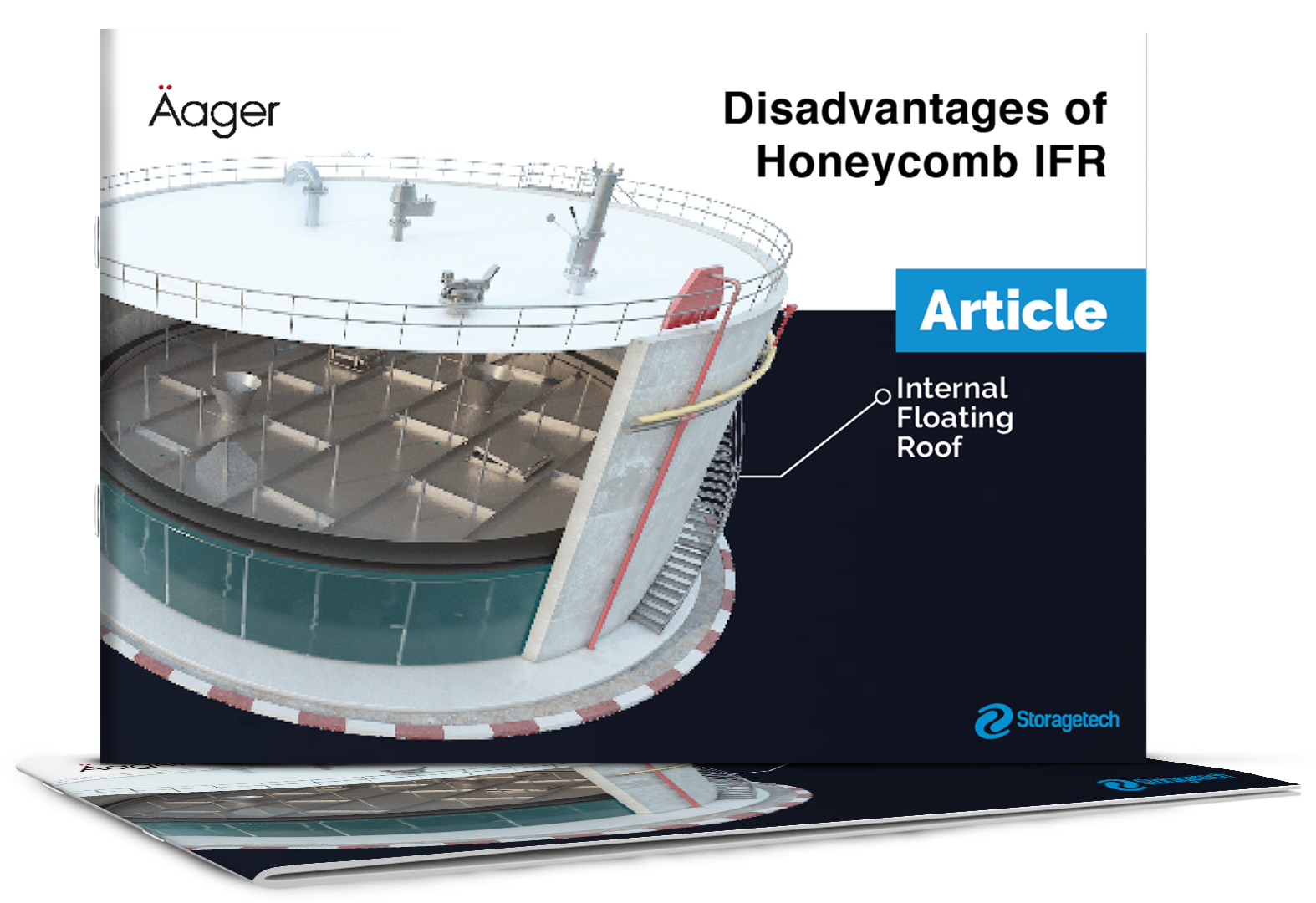

Disadvantages of Honeycomb Internal Floating Roof

While honeycomb sandwich structures offer numerous advantages, including high strength-to-weight ratio, corrosion resistance, and design flexibility, there are also some disadvantages associated with this type of structure, particularly when used in storage tank internal floating roofs. Here are some potential drawbacks:

Fluid Intrusion:

Honeycomb sandwich structures are prone to fluid intrusion. This is a significant concern when used in storage tank internal floating roofs, where contact with stored product, and water can occur. Fluid intrusion may compromise the structural integrity of the honeycomb core over time.

Effect of Vapor Intrusion:

In addition to fluid intrusion, the vapor intrusion can also have specific effects on honeycomb type storage tank internal floating roofs:

Vapor Permeability:

Honeycomb structures may have varying degrees of vapor permeability depending on the material used. Vapor intrusion, especially of aggressive or corrosive vapors, may affect the structural components and compromise the integrity of the internal floating roof. Honeycomb panel sealing is highly susceptible to outside effects and even if it is carefully applied, lifetime is very short compared to welded panels.

Material Degradation:

Prolonged exposure to vapors, especially those carrying corrosive elements, can contribute to material degradation. This degradation may impact the mechanical properties of the honeycomb core, potentially leading to structural weaknesses.

Chemical Compatibility:

The chemical compatibility of the honeycomb material with specific vapors becomes crucial. Some vapors may react with the material, affecting its strength and stability over time.

Potential for Corrosion: Vapors containing corrosive elements can contribute to the corrosion of the facesheet and core material. Corrosion weakens the structure and may compromise its ability to withstand loads and environmental conditions.

Compressive Strength Degradation:

Exposure to certain fluids or vapor over an extended period, as demonstrated in the study, may lead to a degradation of the compressive strength of the honeycomb core. This reduction in strength could compromise the overall structural performance of the storage tank internal floating roof.

Recovery Issues:

Even if the specimens are dried after exposure to fluids or vapor, it is suggested that the recovery of the compressive strength of the honeycomb core may not be complete. This incomplete recovery could raise concerns about the long-term durability and reliability of the honeycomb structure, especially in applications where sustained strength is critical.

De-bonding Between Facesheet and Core:

The investigation into de-bonding between the facesheet and core material after soaking indicates another potential issue. De-bonding can lead to a loss of structural cohesion, affecting the overall performance of the honeycomb sandwich structure.

Limited Resistance to Certain Fluids & Vapors:

Depending on the specific fluid & vapor exposure, certain types of honeycomb cores may exhibit reduced resistance. For example, prolonged contact with aggressive chemicals or fluids with high corrosiveness may lead to accelerated degradation, impacting the structural properties of the honeycomb core.

Complexity of Manufacturing and Inspection:

Honeycomb sandwich structures, being complex in their design, require careful manufacturing processes and thorough inspections to ensure the quality and integrity of the final product. Any defects or inconsistencies in the manufacturing process may lead to vulnerabilities in the structure.

Cost Considerations:

The use of composite materials, including honeycomb sandwich structures, may involve higher initial costs compared to traditional materials like aluminum or steel. While the long-term benefits may outweigh the costs, it’s essential to consider budget constraints.

In summary, while honeycomb sandwich structures offer numerous advantages, the potential for fluid intrusion and its impact on structural properties highlights the importance of thorough testing, maintenance, and consideration of alternative materials in applications such as storage tank internal floating roofs. Engineers and designers need to carefully weigh the benefits against the potential drawbacks to determine the suitability of honeycomb structures for specific applications.

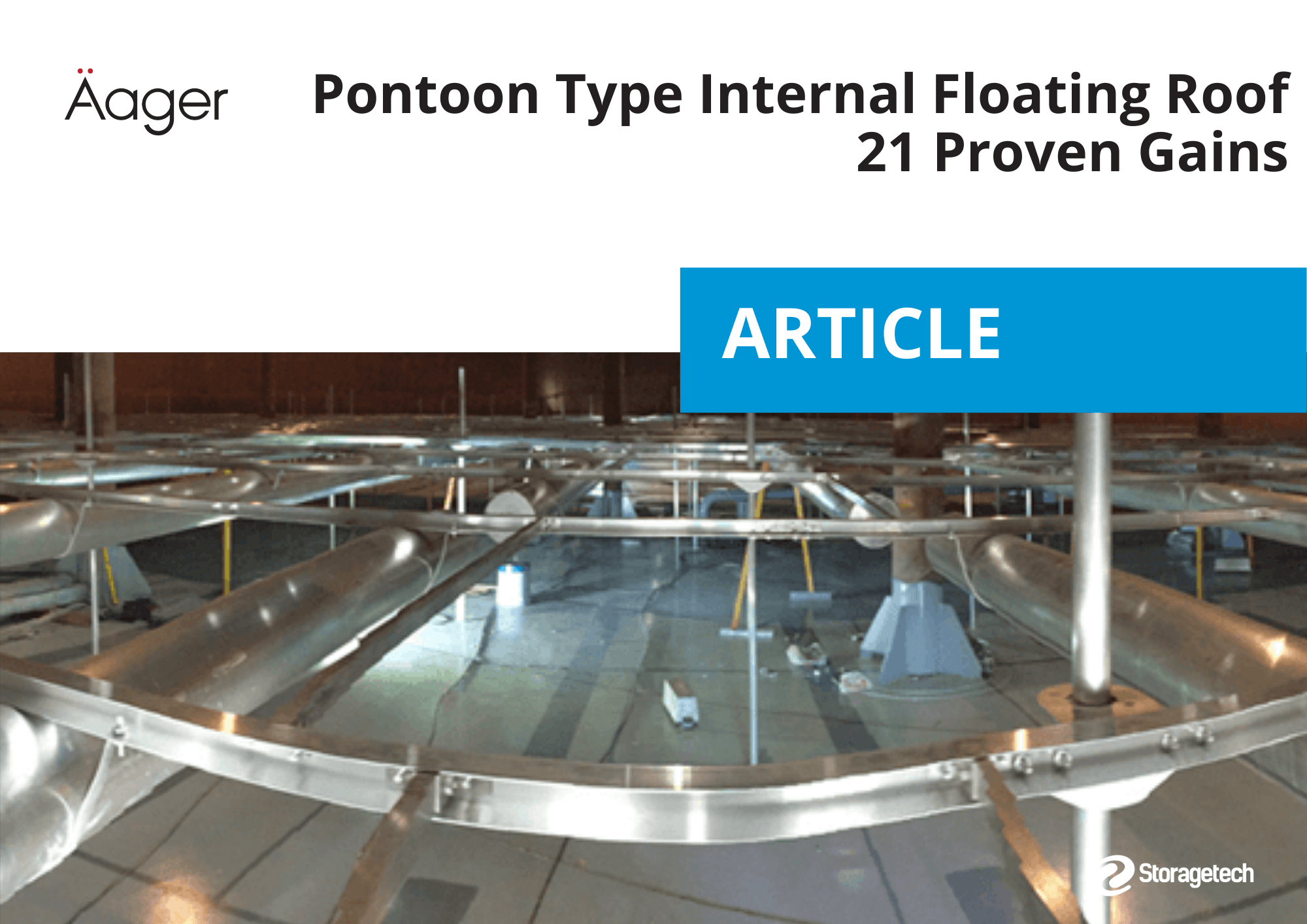

Alternatives to honeycomb full-contact internal floating roof:

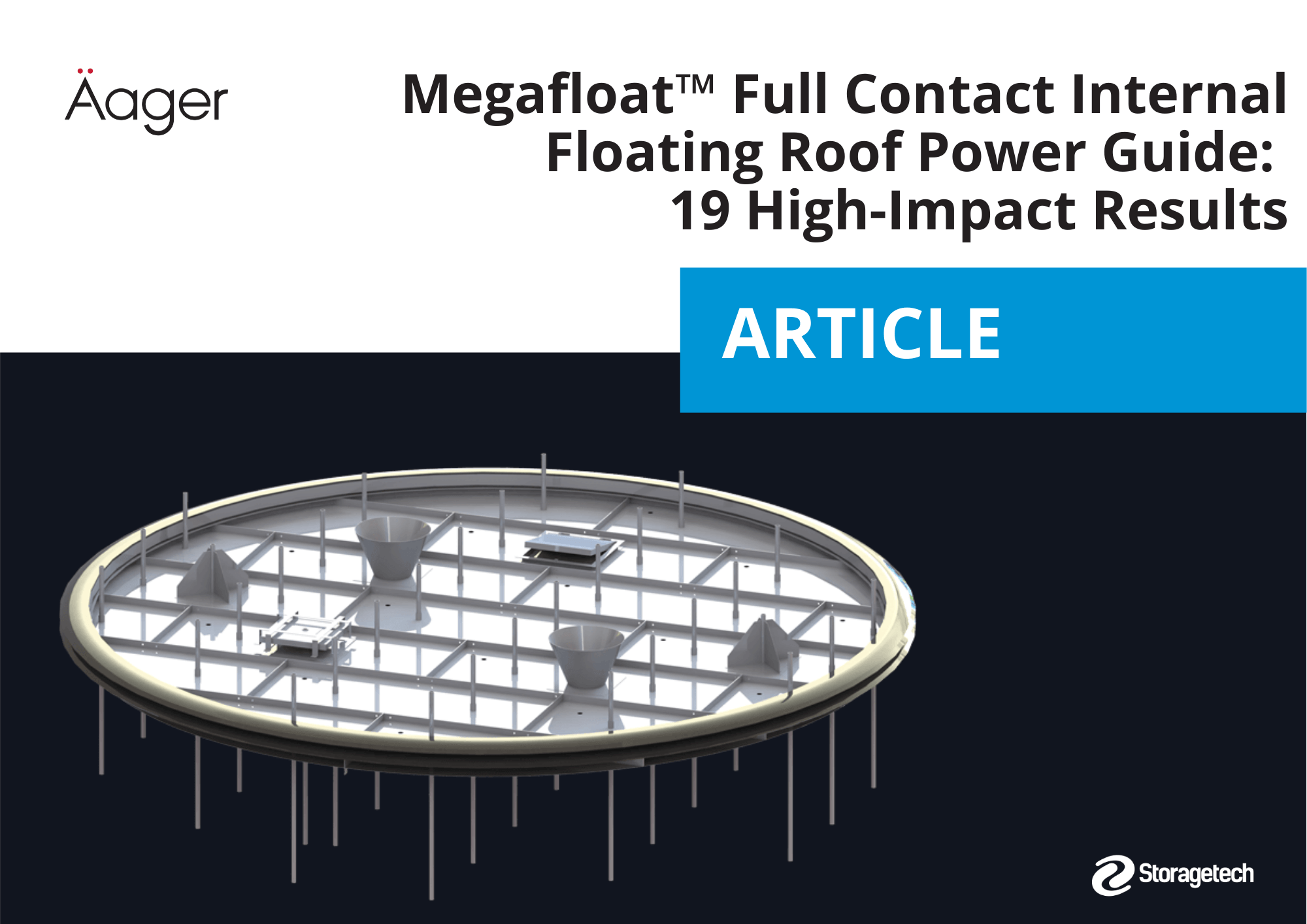

Megafloat welded box type.

GRP composite type

Closed-cell polyurethane sandwich panel type.

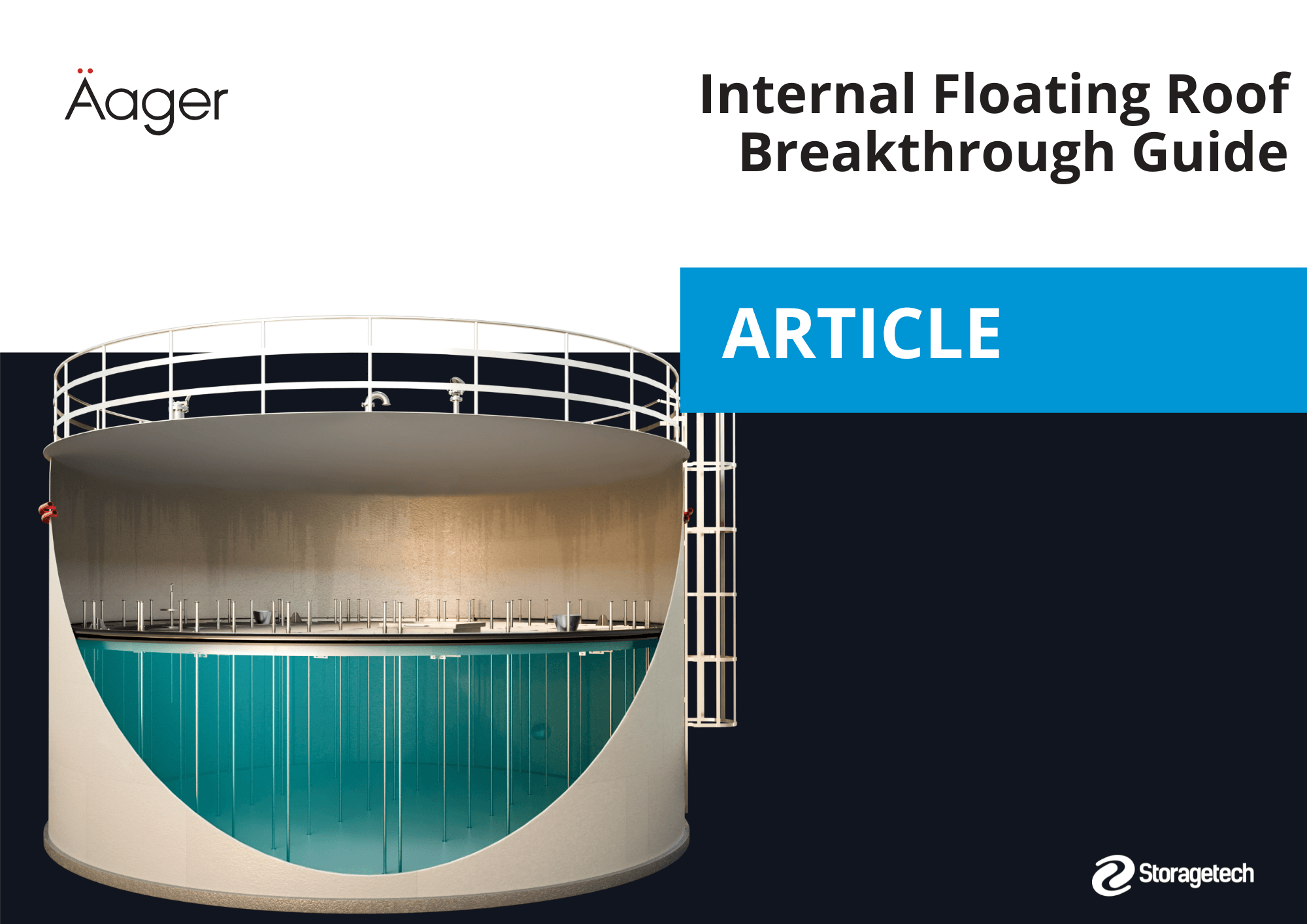

Assessing the Suitability of Honeycomb Sandwich Structures in Storage Tank Internal Floating Roofs

Honeycomb sandwich structures are celebrated for their high strength-to-weight ratio, corrosion resistance, and design flexibility. However, their application in storage tank internal floating roofs presents unique challenges. This article explores the potential drawbacks of using honeycomb structures in such settings, examining fluid and vapor intrusion, material degradation, and other critical factors.

The Drawbacks of Honeycomb Structures in Storage Tanks

Fluid Intrusion Risks

Honeycomb sandwich structures are susceptible to fluid intrusion, particularly when in contact with stored products or water in storage tank roofs.

This intrusion can compromise the structural integrity of the honeycomb core over time, leading to potential failures.

Vapor Intrusion and Its Effects

Honeycomb structures’ varying vapor permeability can be problematic, especially when exposed to aggressive or corrosive vapors.

Such exposure may weaken the structural components, shortening the lifespan of the internal floating roof.

Material Degradation Concerns

Prolonged exposure to corrosive vapors can degrade the honeycomb material, affecting its mechanical properties and leading to structural weaknesses.

Chemical Compatibility Issues

The interaction of certain vapors with the honeycomb material can adversely affect its strength and stability over time.

Corrosion Potential

Facesheet and core materials are at risk of corrosion from vapors containing corrosive elements, which can significantly weaken the structure.

Compressive Strength Degradation

Extended exposure to fluids or vapors may degrade the compressive strength of the honeycomb core, compromising the roof’s structural performance.

Incomplete Recovery Post Exposure

Even after drying, the honeycomb core may not fully recover its compressive strength, raising long-term durability concerns.

De-bonding Risks

Potential de-bonding between the facesheet and core material can lead to structural cohesion loss, affecting overall performance.

Limited Resistance to Certain Fluids and Vapors

Honeycomb cores may exhibit reduced resistance to aggressive chemicals, leading to accelerated degradation.

Manufacturing and Inspection Complexity

The intricate design of honeycomb structures demands precise manufacturing and thorough inspections, with any deviations posing risks to structural integrity.

Cost Considerations

Despite their long-term benefits, honeycomb sandwich structures may incur higher initial costs compared to traditional materials like aluminum or steel.

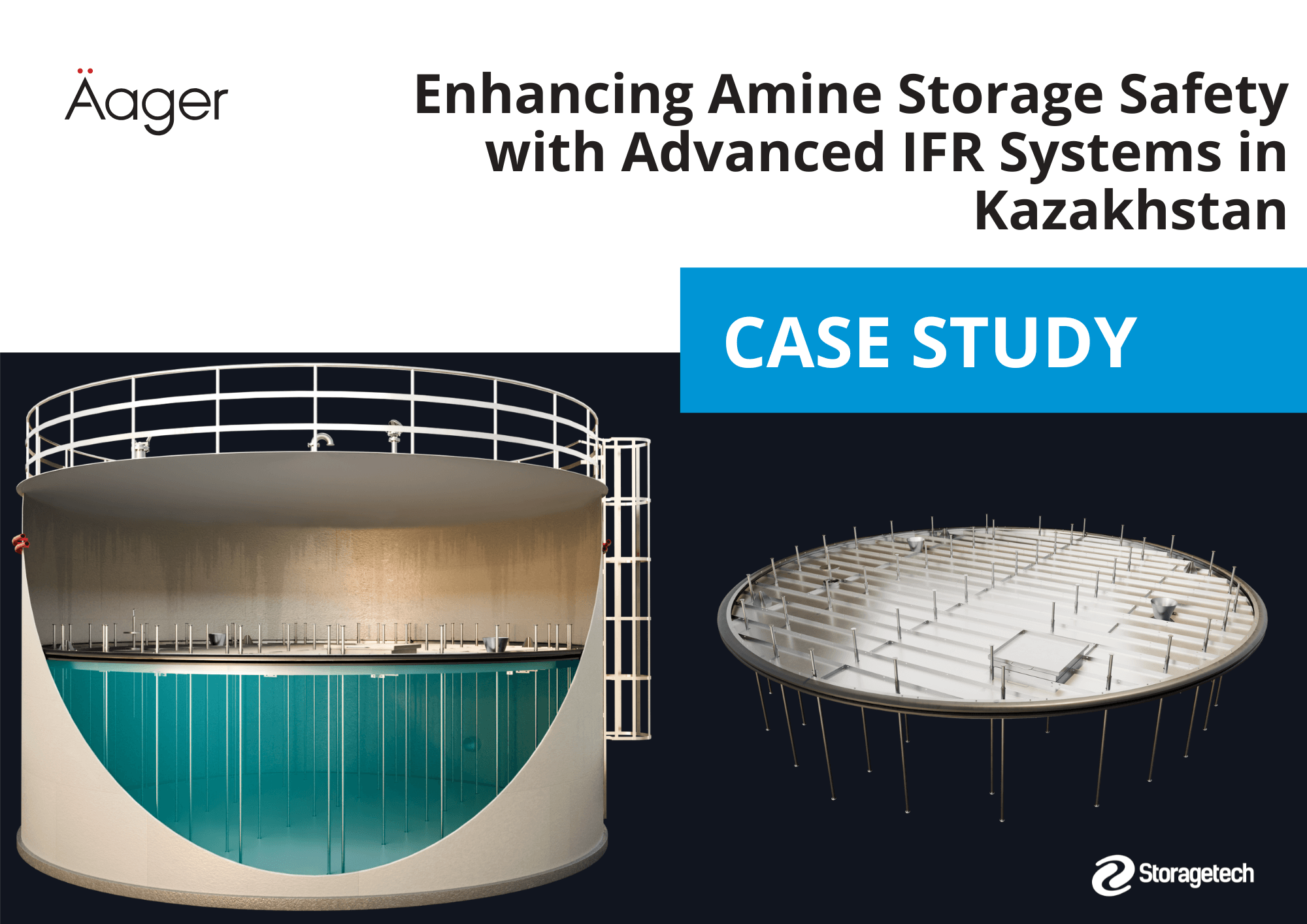

Exploring Alternatives

Given these challenges, exploring alternatives to honeycomb structures is prudent, especially for applications demanding robust long-term performance. Alternatives include:

Megafloat Welded Box Type: Offers robustness and resistance to fluid and vapor intrusion.

GRP Composite Type: Provides corrosion resistance and durability.

Closed-Cell Polyurethane Sandwich Panel Type: Ensures better fluid resistance and structural stability.

While honeycomb sandwich structures bring numerous advantages, their application in storage tank internal floating roofs demands careful consideration. The potential for fluid intrusion, material degradation, and other challenges necessitates a thorough evaluation of their suitability. Engineers and designers must balance these drawbacks with the benefits, ensuring the chosen solution aligns with the specific requirements of storage tank applications. The exploration of alternative materials and structures plays a crucial role in this decision-making process, guiding the industry towards safer and more efficient storage solutions.