Introducing Storagetech’s Floating Suction Unit: Precision-Engineered Excellence for Jet A Aircraft Fuel Storage

Unlock unmatched efficiency and reliability in your aviation fuel storage with StoragetTech’s Floating Suction Unit. Meticulously crafted and rigorously tested, this cutting-edge solution sets the standard for performance, functionality, and safety.

Model No: 700

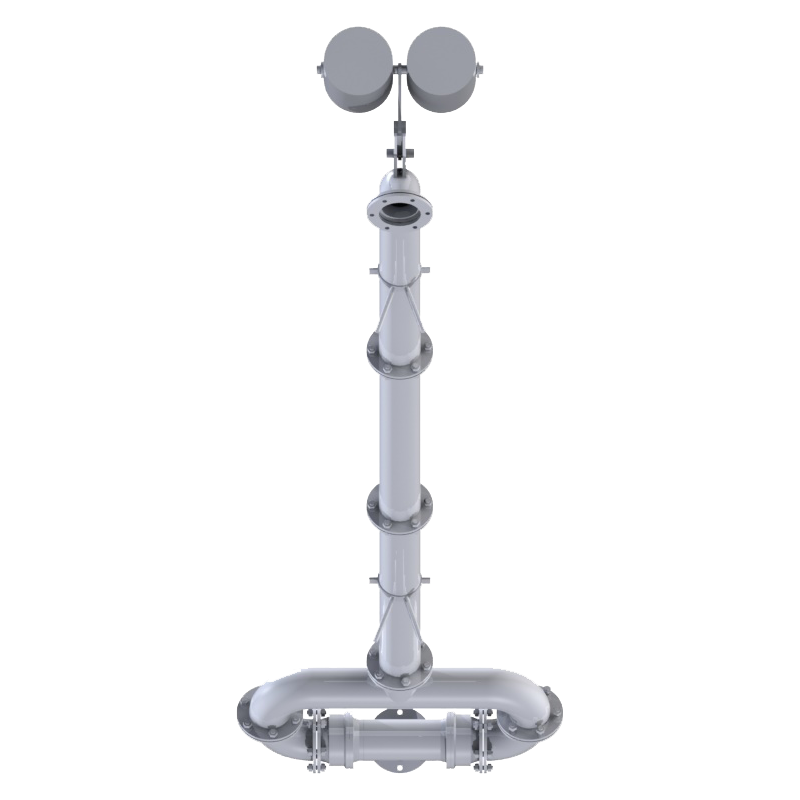

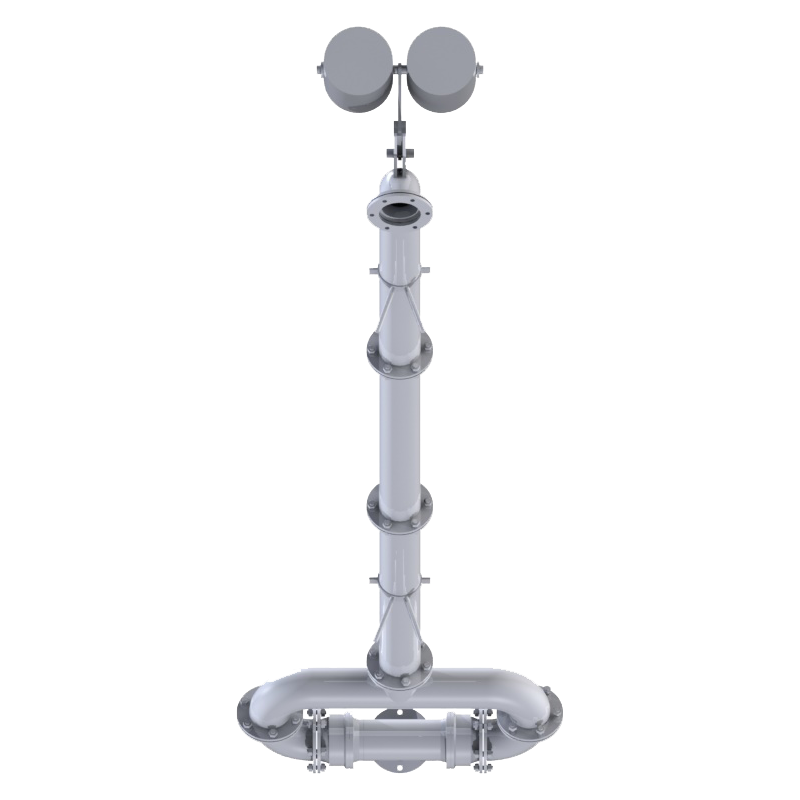

Storagetech’s Floating Suction Unit, Model 700, delivers cleaner products by collecting the fluid closest to the surface. This application is used extensively in aircraft, motor fueling, heating oils, and petrochemicals and has so on an important effect.

Storagetech provides unique and economical solutions including single and double joint suction units for specific applications.

Our Floating Suction Unit is intelligently designed to ensure the efficient extraction of Jet A aircraft fuel. The unit employs a unique swivel joint or flexible joint, providing seamless rotation and avoiding any potential leakage during operation.

Rigorous Pre-shipment Testing:

Prior to leaving our facilities, each Floating Suction Unit undergoes comprehensive testing, guaranteeing its reliability and compliance with the highest industry standards. We take pride in delivering a product that exceeds expectations and ensures peace of mind for our customers.

Adaptable to Customer Needs:

Recognizing the diverse requirements of our customer, we offer the flexibility to choose between a swivel joint or a flexible joint based on customer preferences. This customization ensures that our Floating Suction Units seamlessly integrate into your specific storage system.

Ideal for Jet A Aircraft Fuel and Airport Storage Facilities:

Our Floating Suction Units are purpose-built for Jet A aircraft fuel, making them the preferred choice for airport storage facilities. Their exceptional performance, reliability, and adherence to safety standards make them the go-to solution for the aviation industry.

Compatible with Internal Floating Roofs:

Designed with versatility in mind, our Floating Suction Units can be effortlessly accommodated with internal floating roofs, providing an integrated solution for enhanced storage capabilities.

Materials for Every Occasion:

Tailoring our product to your needs, our Floating Suction Units are primarily crafted from aluminum, stainless steel, and duplex materials. For special occasions, we offer manufacturing in carbon steel, ensuring adaptability to diverse operational requirements.

Additional Accessories Available:

To further enhance your storage system, we provide optional accessories such as level indicators and stored product test accessories. These additions contribute to an advanced and comprehensive solution for your aviation fuel storage needs.

Experience the epitome of innovation in aviation fuel storage. Choose StorageTech’s Floating Suction Unit for unparalleled performance, reliability, and adaptability.

- It gets rich and clean content in the top layer of fuel.

- Heavy metals such as water and dirt in the tank collapse down due to their density.

- These are undesirable substances and are generally eliminated by drainage.

- The floating suction arm engages at this point and remains in the floating position thanks to the pontoon and is positioned on the top surface of the tank and provides suction from this point.

- Generally it consists of 3 main parts. Floating panttons, suction tubes and swievel joints or pivot masters that connect them.

- Connection options are made according to customer requirements and requirements as pivot master if required on the axis of the nozzle and swievel joint if misalignment is required.

- It can be designed as single-arm or multi-arm according to the diameter and liquid operation height of the tank.

- The height of the suction opening can be displayed.

- Fuel height can be measured.

- Internal & External floating roof can be integrated.

- It is possible to design with special support to prevent conflicts according to the internals.

- It can be manufactured with any kind of material. (CS, SS, AL, Duplex, Hastelloy, etc.)

- Connection joints are klinger, nitrile, viton, teflon, rubber, etc.

- The design is carried out through the existing manhole.

- All stress, performance and flow analyzes are performed.

- The plugs made of polyamide or teflon.

- Special designs can be realized upon request.

- Sealing and movement tests are carried out in our factory.

- Can be manufactured from ½” to 40″.

- Low maintenance.

- Suitable for most aggressive products as 100% aromatics.

- It can work in the range of -50 degrees to 200 degrees.

- Connection flanges are carried out in accordance with all standard flanges according to customer specifications.

- Filtration unit can be installed in the suction port for higher performance.

- Anti vortex device is available.

Deflagration vs Detonation

Learn the key differences between deflagration and detonation.

Combustion Process

Explore the science behind combustion and its applications.

Explosion Groups

Discover the different types of explosions and our products.

Request a Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon