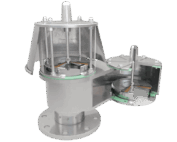

Model No: 400

Storagetech’s Weight-loaded Emergency Relief Vent, model 400, operates as the last resort when a vessel or storage tank is exposed to large-scale fire, and the standard pressure relief valve has failed to open or cope with the extreme conditions.

A high rate of gas transfer occurs during a fire due to the increased evaporation rate, and these gases are released into the atmosphere via the emergency relief valve. The cover is manually placed back in place to guarantee tightness when the fire case would be resolved.

There is a choice of pressure release settings to enable a selection close to the maximum working pressure of the vessel.

The weight-loaded emergency pressure relief vent is installed in the horizontal plane on a flange at the top of the tank. A secondary use of the unit is to access the tank for product sampling or depth gauging.

| Pressure | Weight-loaded +2.0 mbar and +60 mbar. (+0.8 inch W.C and +24 inch W.C) |

| Ambient temp | -20°C to +60°C |

| Sizes | 6” to 30” 150 to 750mm |

| Body / Flange | 1-) Carbon steel 2-) Stainless steel 316 or 304 3-) Customer Specification |

| Flanges drilling | API Class 150, DIN PN 16, Special |

| Seals | Nitrile, Special |

| Paint finish | 1-) Powder Coating, Colour RAL 9006 2-) Epoxy Paint, Colour RAL 9006 3-) Customer Specification |

| ATEX cert | Ex II 1/2 G c IIB |

The integrity of the seal is tested for leakage in accordance with API Standard 2521 – Use of Pressure-Vacuum Vent Valves for Atmospheric Loss.

The size of the vent should be calculated in accordance with API Standard 2000 (ISO 28300) – Venting Atmospheric and Low-Pressure Storage Tanks or other international standards.

Deflagration vs Detonation

Learn the key differences between deflagration and detonation.

Combustion Process

Explore the science behind combustion and its applications.

Explosion Groups

Discover the different types of explosions and our products.

Request a Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon