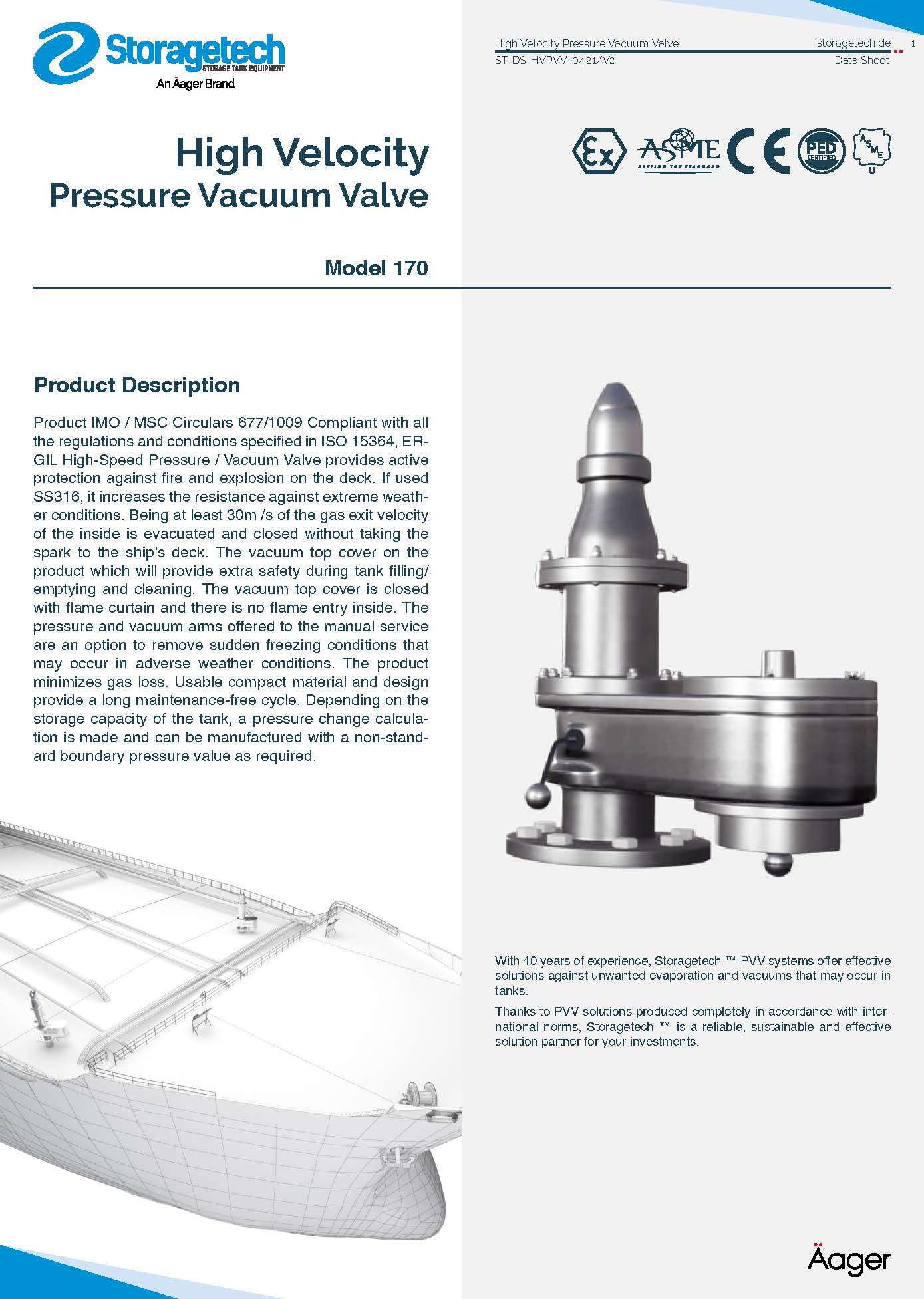

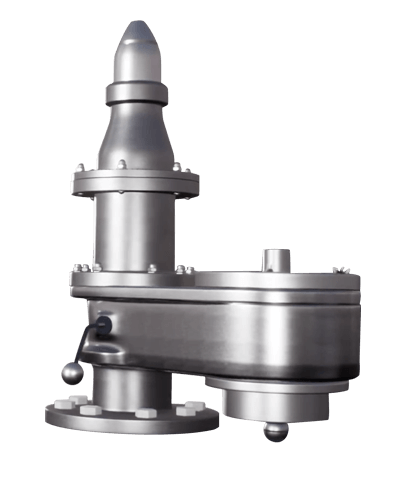

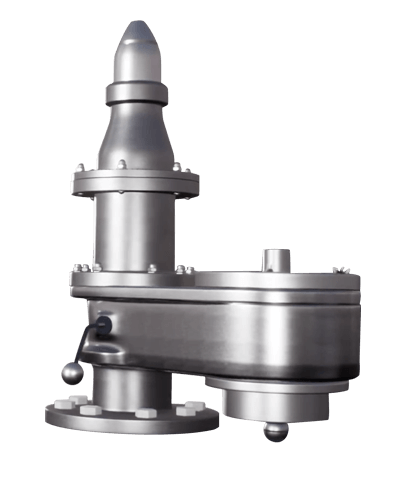

Storagetech’s innovative High-Velocity Pressure Vacuum Valve (also called High-Speed Pressure Vacuum Relief Vent or PVV), Model Number 170 is a safety device that reduces evaporation in cargo tanks. It is designed to prevent over and under pressure in the tank atmosphere. Thus, when air pressure exceeds the preset setting of the pressure vacuum vent, the pallets open, depart the seal between the seal and pallet, and expel any excessive positive pressure. Moreover, they are typically mounted to a flange or pipe, which connects the vapor space of a cargo tank. In this respect, the ventil can be set to your specifications so that the pallet assemblies in the housings open when specific pressure and vacuum levels are reached. Storagetech cargo vents work automatically. As opposed to the open tank free venting system, it controls the cargo tank venting system.

Storagetech High-Velocity Pressure Vacuum Valves are designed specifically for tough offshore conditions. The valve body and internals are made of completely stainless steel ss 316 material that minimizes the corrosion effect. The highly technical design helps smooth functioning during sailing. The special loaded magnet design keeps the set pressure at the required setting and opens immediately releasing the vapor high above the ship’s surface. This jet-releasing mechanism avoids any vapor collection on the surface of the ship and creates a safe operation. Storagetech High-Velocity PVV can safely operate up to -25ºC and the manual lifting handle helps to break the ice on both the pressure and vacuum sides.

In this design, we have decided to use the ring magnet to provide both continuities and prevent magnetic failure. We have designed and manufactured most of our product exterior and interior parts from AISI 316 material as this it reduces the effect of corrosion caused by the high humidity in the sea environment and the sea/ocean water itself, thus providing our utilities a long servicelife in overseas travels.

• Storagetech PVV Model 170 High-Velocity Pressure Vacuum Valve prevents evaporation losses.

• The pressure/vacuum relief valve is the automatic gas-freeing high-speed valve of non-hammering non-oscillating type which ensures gas emission velocity with the vacuum valve equipped with a flame screen.

• The high-speed valve provides automatic pressure control during cargo loading and during passage for changes caused by thermal variations.

• The vacuum valve provides automatic vacuum control during cargo discharge and during passage for changes caused by thermal variations.

• Protects environment. High-Velocity PVV prevents greenhouse gases from mixing in the atmosphere and minimizes the product odors around the surrounding area.

• High-Velocity PVV provides safety for your storage facility. High-Velocity PVV protects your storage tank from explosions that are caused by sudden pressure and vacuum change.

• Designed to prevent the passage of flames into tanks carrying oil & chemical.

• High-Velocity Pressure/Vacuum Valve provides active protection against fire and explosion on deck.

• 2_NEW IMO Regulation for Product & Chemical carriers, MSC.1/Circ,1324

1-The Maritime Safety Committee approved the following amendments to MSC/Circ.677:

A-Paragraph 1.2.3 is replaced with the following

*1.2.3 These Standards are intended for devices protecting cargo tanks containing crude oil, petroleum products, and flammable chemicals. In the case of the carriage of chemicals, the test media referred to in section 3 can be used for products having an MESG of 0.9 mm and greater. However, devices for chemical tankers certified for the carriage of products with an MESG* less than 0.9 mm should be tested with the following media based on the apparatus group assigned as per column “i” of the IBC Code, chapter 17:

1. Apparatus Group II B – ethylene (MESG = 0.65 mm); and

2.Apparatus Group II C – hydrogen (MESG = 0.28 mm).

Where no apparatus group is assigned in the column “i”, the device should be tested in accordance with the requirements for Apparatus Group II B.

Deflagration vs Detonation

Learn the key differences between deflagration and detonation.

Combustion Process

Explore the science behind combustion and its applications.

Explosion Groups

Discover the different types of explosions and our products.

Request a Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon