Floating Roofs & Seals Models

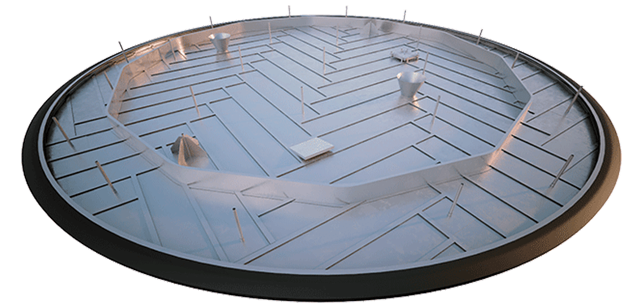

Storagetech is proud to use in all product categories the highest quality standard. Floating roofs and seals are one of them. These products are made from the highest quality materials and are subject to strict quality controls to ensure their reliability and performance.

To further ensure the reliability and performance of our floating roofs & seals, we have implemented a strict control process for the materials used in their production. This process helps us minimize the risk of mistakes and defects, ensuring that you receive the highest quality product possible.

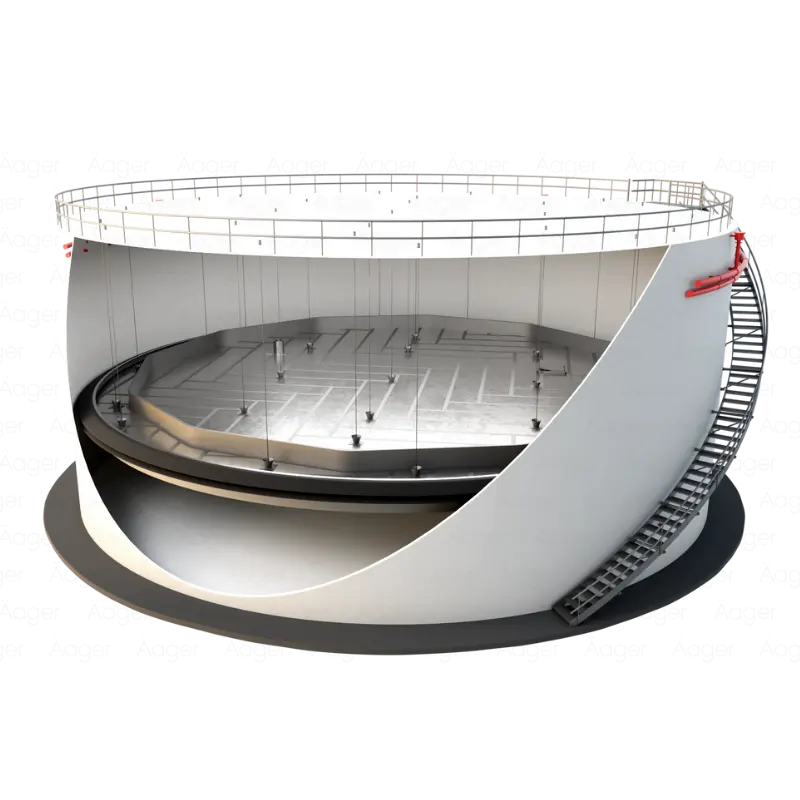

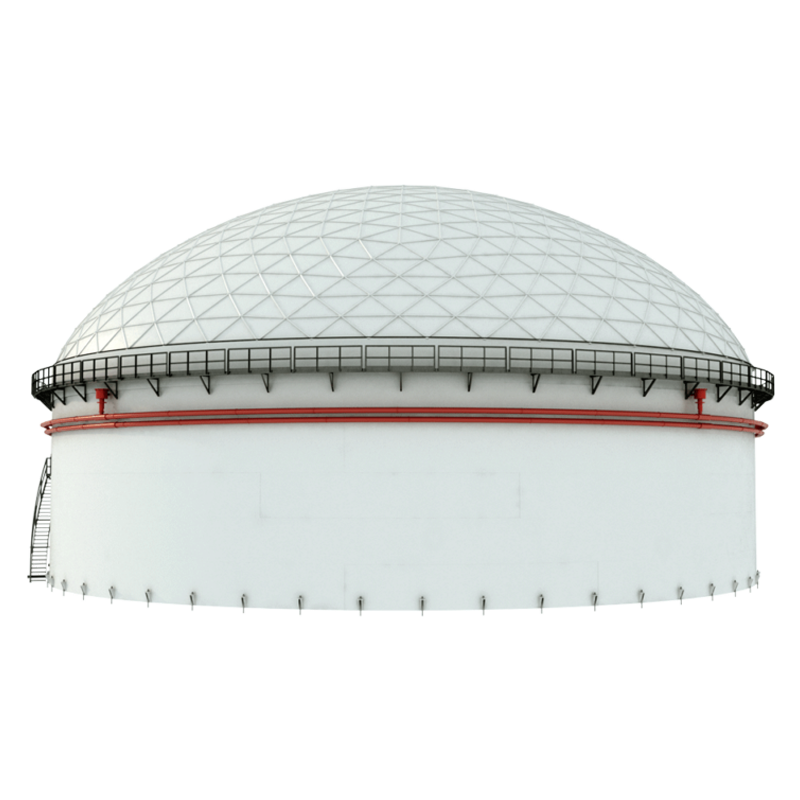

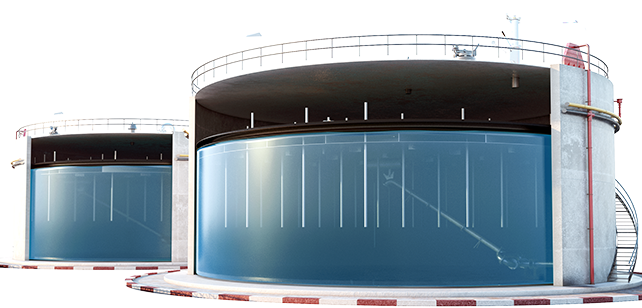

Storagetech floating roofs and seals are engineered to provide maximum stability and durability. The products are designed to provide a tight seal to prevent the loss of stored products such as jet fuels, gasoline, diesel, and crude oil. Their performance enables long-time usage in the operation.

Floating roofs and seals aim to eliminate evaporation losses and also provide economic and environmental benefits. Due to this versatile usage, these products are a critical part of tanks for our customers. Storagetech is aware of these and offers the highest performance with the best solutions.

Storagetech’s first priority is to listen to the exact needs of its customers for more than 40 years. Floating roofs and seals are therefore also customized products that meet the specific requirements of customers.

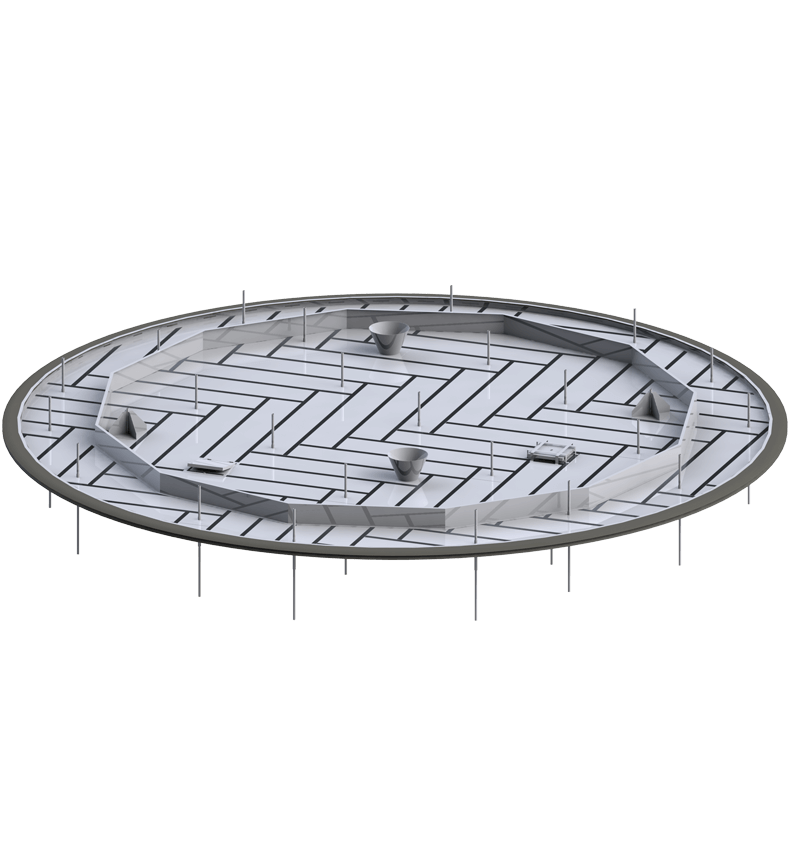

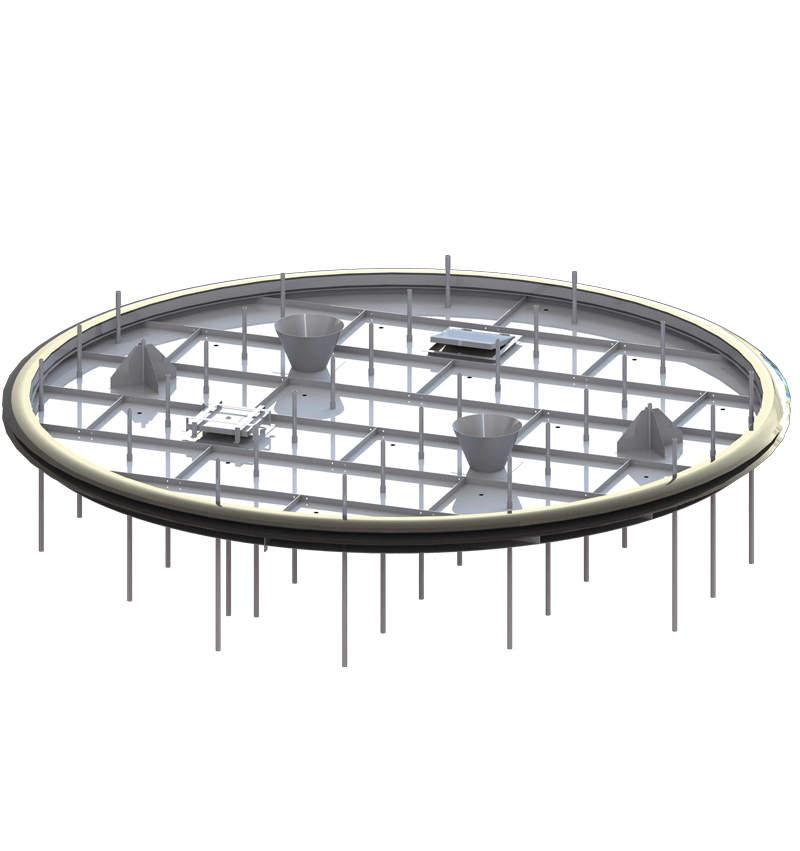

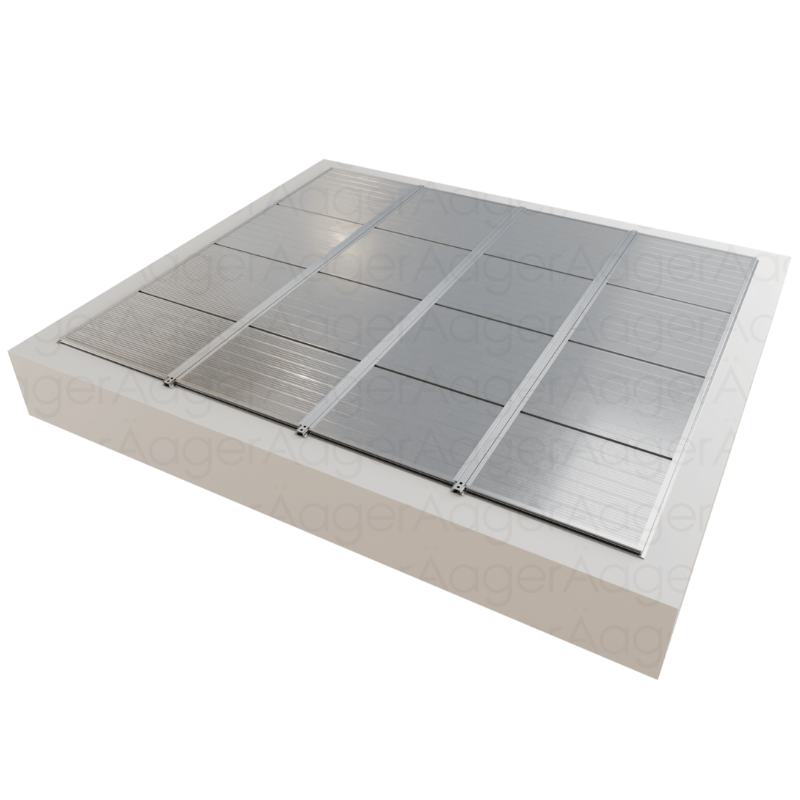

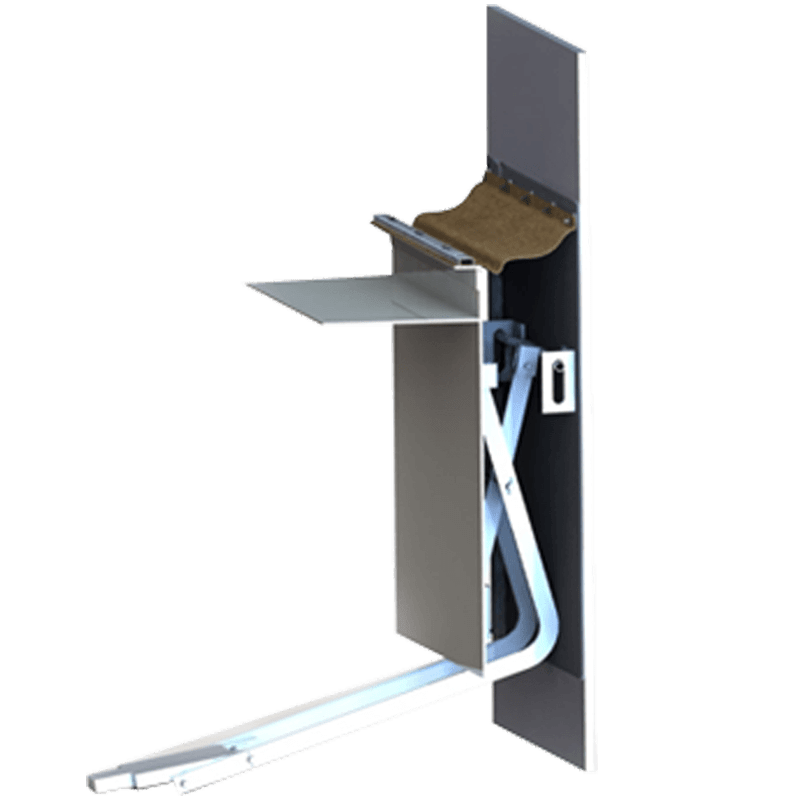

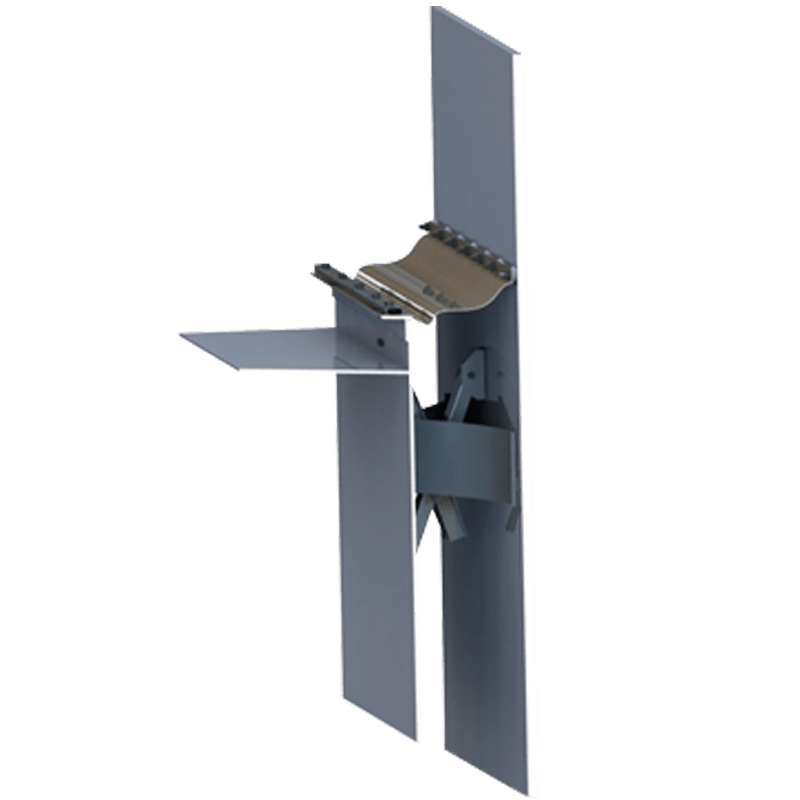

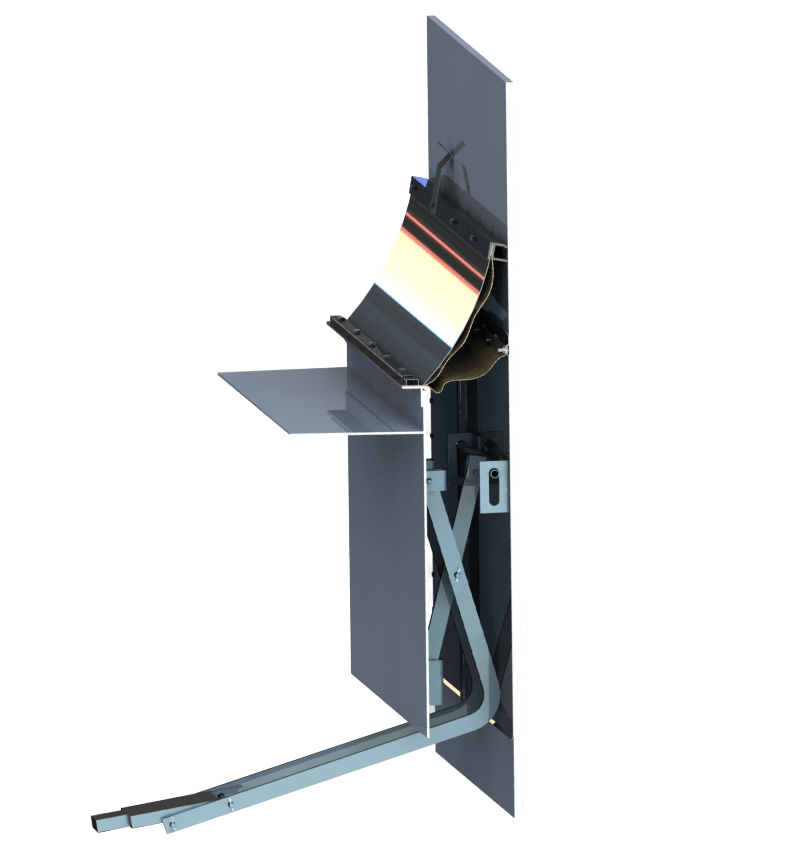

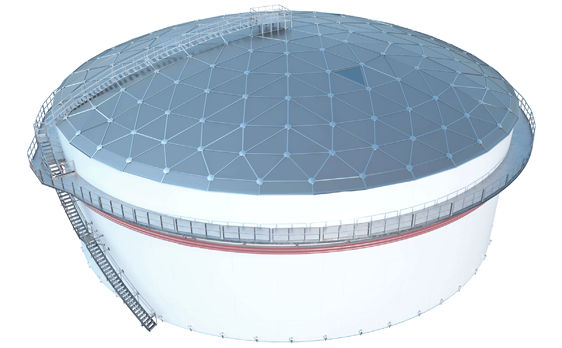

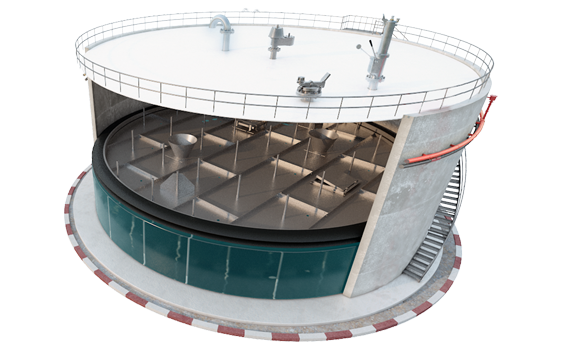

Storagetech can customize storage products based on technical details and the best suitable solution. Customized options include internal and external floating roofs, scissor-type and pantograph-type systems, and full-contact roofs. All of these products can be tailored to meet the specific needs of customers.

Storagetech is able to use different types of materials for floating roofs and seals. We offer a range of material options including aluminum, steel, and composite. The usage is proved by our engineering team and R&D team first. After that, it is interpreted into our products.

The choice of materials allows Storagetech’s customers to choose the best option for their specific needs and budget. In all cases, the quality and performance of the products are kept at the desired level.

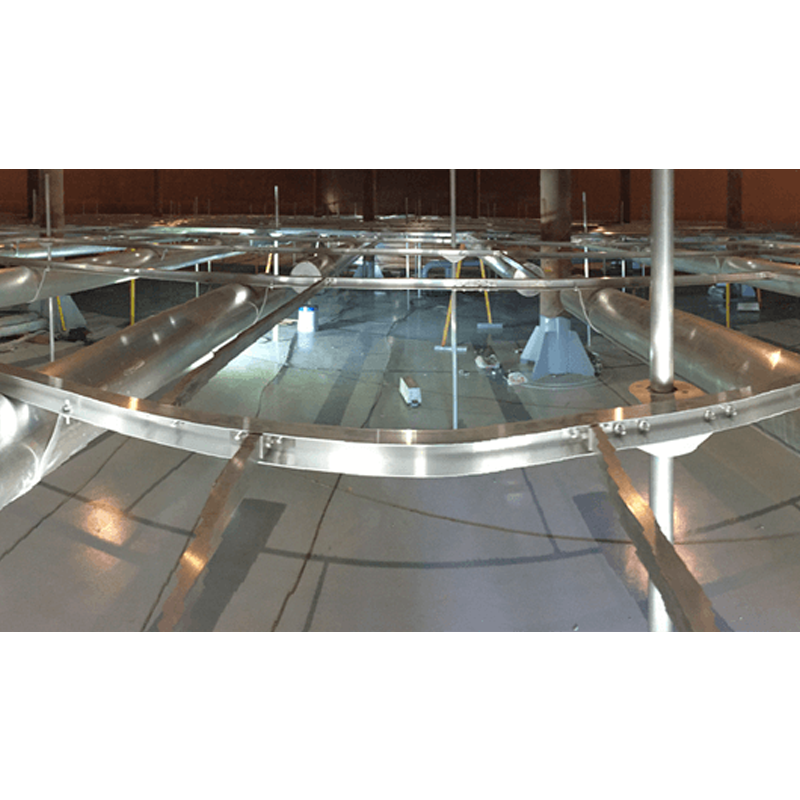

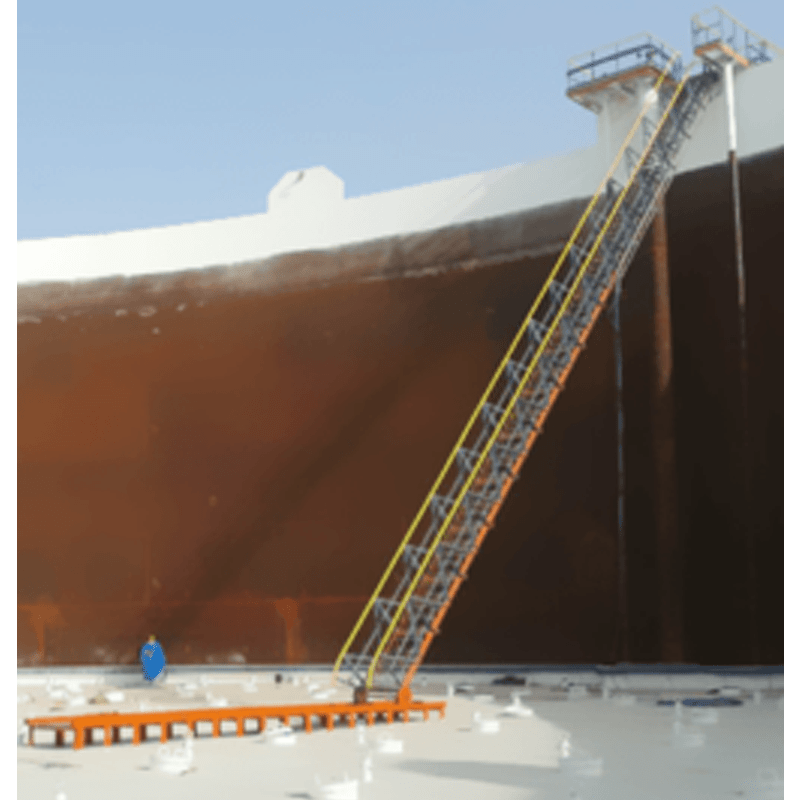

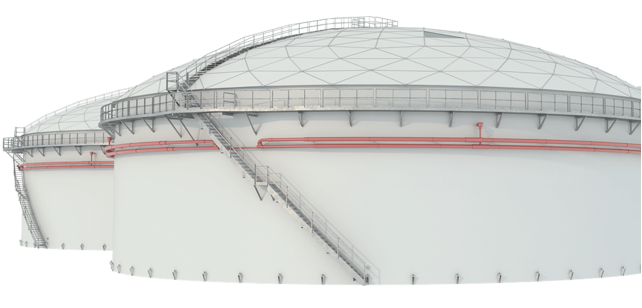

Storagetech’s engineering know-how in the sector enables the best solutions for its customers. This know-how is critical for floating roofs and seals because their usage effects directly the status of the storage product. The manufacturing, installation, and control process requires expertise.

The expert team of Storagetech is always on hand to provide support and guidance, ensuring that their customers get the right product for their needs. Also, the installation process is followed so that the product works correctly. This enables economic and environmental values for their customers.

Storagetech floating roofs and seals are designed for ease of installation. The used materials enable cost-effective solutions for the installation. The installation at the site is reduced. This enables a quicker execution of the project and its usage.

The ease of installation makes Storagetech floating roofs and seals a convenient and cost-effective solution for any application. Whether you are looking to upgrade your storage tanks or are in need of new floating roofs and seals, Storagetech has the products and expertise to meet your needs.

Why to choose Storagetech Floating Roofs & Seals?

Request a Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon