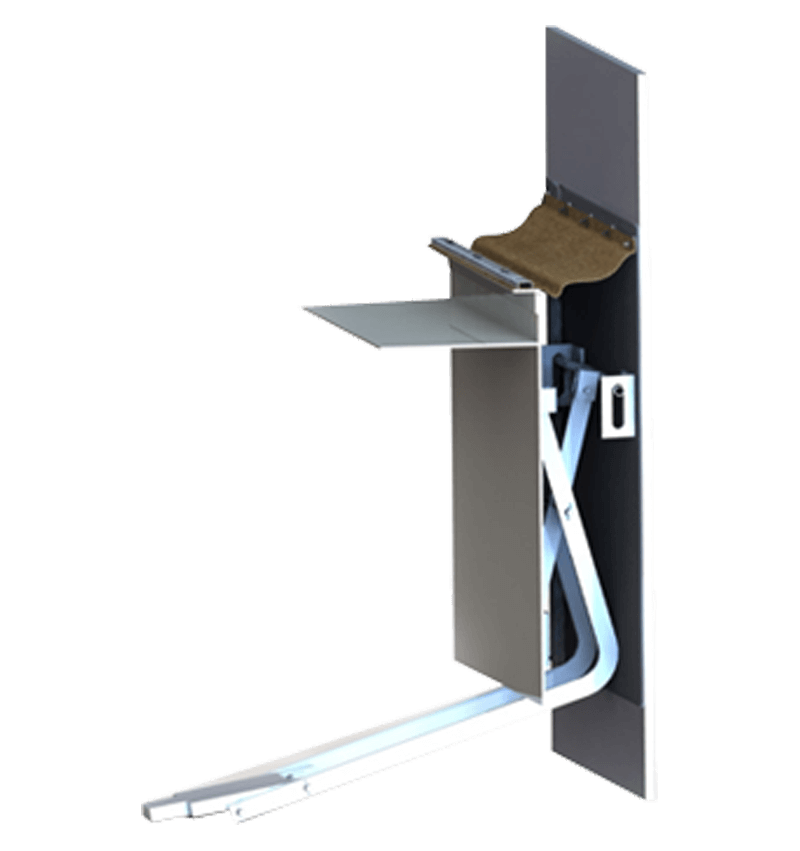

Due to the force exerted by the weights, the pressure at the top and bottom of the mechanical seal is optimized. The weighted structure, along with the use of materials thinner than carbon steel and aluminum, eliminates the need for extra weight. As a result, the system effectively minimizes product leakage by using the pressure generated by the springs, in contrast to the weighted system. The efficient sealing performance can accommodate gaps up to 200 mm and operates within a ±100 mm tolerance range.

Design Features

Each seal is customized to fit the tank to ensure maximum performance, long life, and safe operation. Primary seals include a variety of configuration and component options. The shoe is connected by braces to the floating deck and is held tightly against the wall by springs or weighted levers a flexible coated fabric (made of Teflon) is suspended from the shoe seal to the floating deck to form a vapor barrier over the annular space between the deck and the primary seal. Storagetech Liquid mounted Primary shoe seals can be categorized as PANTOGRAPH and SCISSOR type seals. The most important issue that affects the performance of the sealing system is that the load which is applied to the shoe seals needs to balance and this force covers all openings through the rim. Mechanical seal systems are restricted to the lined storage tanks for not to damage the cladding material.

When it comes to sealing solutions for the oil and gas industry, look no further than our top-notch pantograph seals. Designed to meet the stringent demands of this sector, our pantograph type seals guarantee superior performance and reliability. As reputable pantograph seal manufacturers, we pride ourselves on delivering high-quality products at competitive prices, ensuring utmost satisfaction for our clients.

Whether you’re in need of a reliable pantograph fuel system or specialized sealing solutions, our comprehensive range has you covered. Trust in our expertise and experience to provide you with the perfect sealing solution tailored to your specific requirements. Choose us for unparalleled quality and efficiency in the oil and gas industry.

Part List

| No | Part Name | Material | Remarks |

|---|---|---|---|

| 07 | Foam Dam, Thk.3mm | Optional | – |

| 06 | Rim Clamp | A653 / G90 | – |

| 05 | Fabric | Teflon | – |

| 04 | Braces ASTM SA 240 gr. 304/316 S235 JR (G) | 1/4 Hardened | – |

| 03 | Rim Clip | ASTM SA 240 gr. 304/316 S235 JR (G) | 1/4 Hardened |

| 02 | Shoe Bracket | ASTM SA 240 gr. 304/316 S235 JR (G) | 1/4 Hardened |

| 01 | Shoe Plate | ASTM SA 240 gr. 304/316 S235 JR (G) | 1/4 Hardened |

Request a Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon