Get Flame Arrester Price

Flame arresters are critical for minimizing fire and explosion risks in industrial facilities, and they’re Storagetech™’s area of expertise.

With over 40 years of experience, we’re one of the industry’s leading brands in ATEX-certified flame arrester design and manufacturing.

We will work with you to understand your specific needs and provide you with a customized solution that meets your requirements and budget. Don’t hesitate to request a quote from us for your flame arrester system needs.

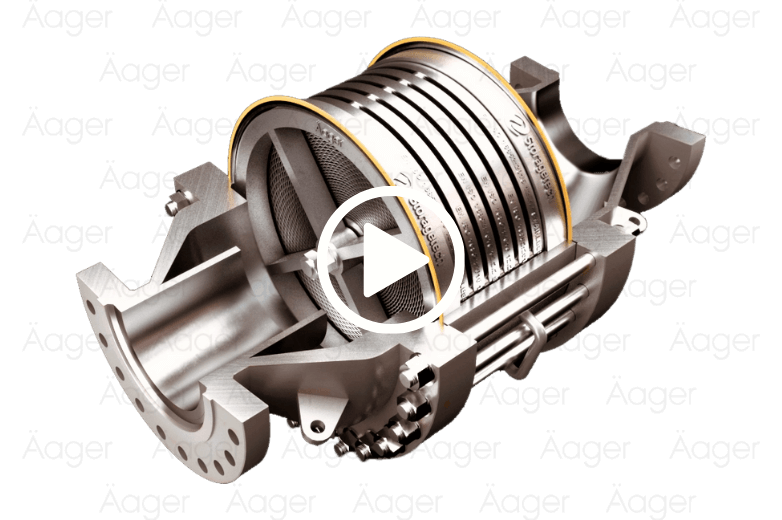

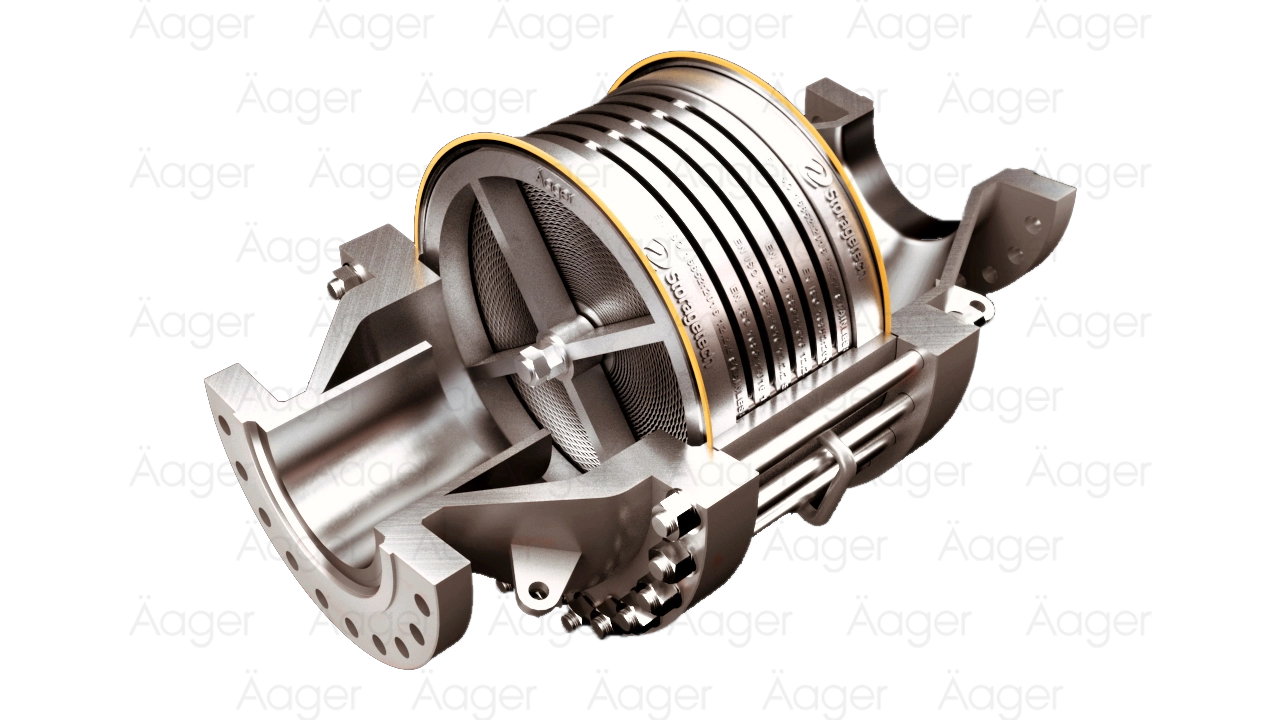

Storagetech™ Flame Arrester

Crucial Part of Your Pipeline Operation Integrity

- ATEX-Certified Safety: Production compliant with the most rigorous industrial standards

- Wide Application Range: Reliable protection in petrochemical, chemical, pharmaceutical, and wastewater treatment facilities

- High Performance: Advanced technology design effectively preventing flame propagation

- Customizable Solutions: Various models suitable for different industrial needs

- Long-lasting Durability: Materials and craftsmanship resistant to challenging operating conditions

Flame Arrester Models

In-Line Flame Arresters

End of Line Flame Arresters

At Storagetech, we are proud to offer flame arresters that are engineered to the highest standards of quality and performance. Our team of experienced engineers and technicians use only the finest materials and the latest technology in the design and manufacture of our flame arresters.

Our flame arresters are made from durable and corrosion-resistant materials, including carbon steel, stainless steel, aluminum, and exotic alloys. These materials are chosen for their ability to withstand extreme temperatures and pressure, ensuring that our flame arresters can provide the highest level of protection against the spread of flames and explosions.

Storagetech flame arresters are not only made with the highest quality materials, but also engineered with a low pressure drop to ensure minimal disruption to your operations. We ensure our products are certified by both ASME and EN standards and go through rigorous testing and inspection by reputable third-party companies like TUV, BV, and SGS, to ensure that they meet the highest standards of quality and safety.

At Storagetech, we are committed to providing the best possible solutions for your storage tank equipment needs. That’s why we are proud to offer our line of robustly designed flame arrestors.

Storagetech flame arrestors are engineered to provide the highest level of protection against the spread of flames in your storage tanks and vessels. They are designed to withstand extreme conditions and withstand the toughest environments, ensuring that they are able to perform at their best when you need them most.

Storagetech flame arrestors feature a heavy-duty construction that is built to last, with durable materials and a sturdy design that can withstand the rigors of everyday use.

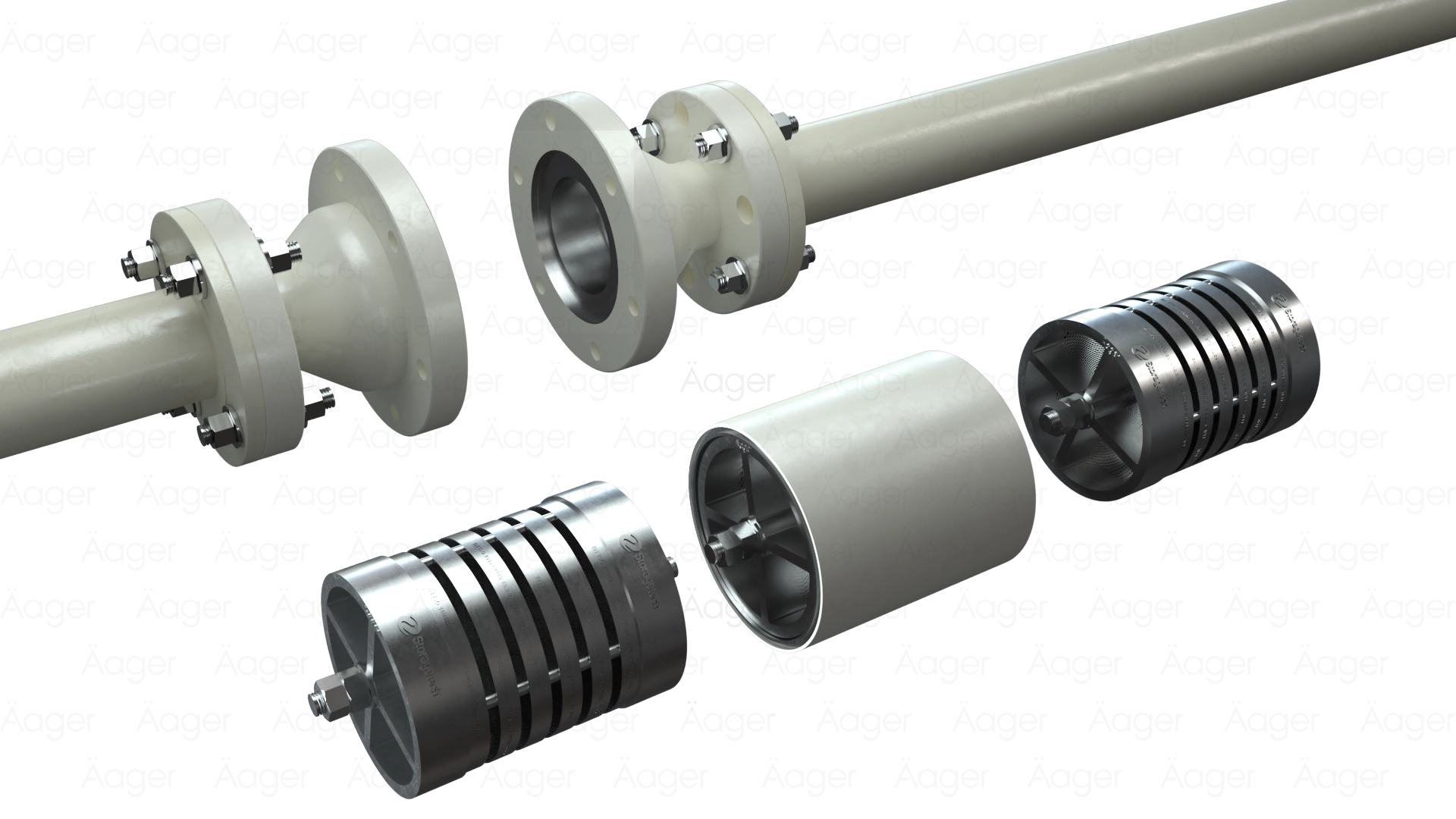

At Storagetech, we understand the importance of easy and efficient installation when it comes to your storage tank equipment. That’s why we are proud to offer our line of flame arrestors that are designed for easy assembling.

Storagetech flame arrestors are engineered to be simple and straightforward to install, saving you time and effort during the setup process. They feature a modular design that allows for quick and easy assembling, with minimal tools and equipment required.

In addition to their ease of assembly, Storagetech flame arrestors are also built to last, with durable materials and a sturdy construction that can withstand the rigors of everyday use. They are an ideal choice for a wide range of applications, including storage tanks, pipelines, and process equipment.

One of the key benefits of Storagetech’s flame arresters is their low pressure drop design. This means that when installed in your system, our flame arresters will not cause a significant drop in pressure, ensuring that your system continues to operate at optimal efficiency.

Not only does this low pressure drop design enhance the performance and reliability of our flame arresters, it also makes them more cost-effective. By minimizing pressure drop, you can save on energy costs and reduce the overall impact on your system.

Our low pressure drop design is achieved through careful engineering and the use of advanced materials.

With decades of experience in the industry, we understand the importance of safety and reliability when it comes to protecting your facility from the spread of flames and explosions. That’s why we are proud to offer flame arresters that are certified by both ASME and EN standards.

Our flame arresters are designed and tested to meet the strictest requirements for safety and performance. They are subjected to rigorous testing to ensure that they can withstand the most demanding conditions, including extreme temperatures and high pressure.

In addition to meeting ASME and EN standards, our flame arresters are also certified by reputable third-party inspection companies such as TUV, BV, and SGS.

Storagetech’s flame arresters are designed to provide the highest level of protection against the spread of flames and explosions in storage tanks, refineries, pipelines, and industrial plants. Our flame arresters are manufactured with the utmost attention to detail, using the latest technology and the highest quality materials.

One key feature of our flame arresters is their protective coating. This coating helps to prevent corrosion and ensure that the arresters continue to function at their best for as long as possible. The coating is applied using advanced techniques and is tested to ensure that it meets the highest standards of durability and performance.

Not only does this protective coating enhance the longevity and reliability of our flame arresters, it also makes them easy to maintain. With minimal upkeep, you can trust that your Äager flame arrester will be ready to protect your facility at all times

Why Storagetech Flame Arresters?

Request a Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon

Read more from us about Flame Arresters!

Flame Arrestors for Industrial Explosion Protection

Flame arrestors (also spelled flame arresters) are critical safety devices used to stop flames from propagating through flammable gas or vapor systems. Storagetech™ – a world-leading industrial flame arrestor manufacturer – offers a comprehensive range of flame arrestors (end-of-line, in-line, deflagration, detonation, etc.) designed to protect facilities in oil & gas, chemical, petrochemical, storage tank farms, marine vessels, pharmaceuticals, and more. In this guide, we’ll explore what flame arrestors are, how they work, the types available, and their applications across industries.

Storagetech’s flame arrestors are built for professional, high-risk industrial environments, combining advanced engineering with over 40 years of experience in explosion protection. All units are fully certified (ATEX, ISO, etc.) and engineered for performance and reliability. Whether you need an inline flame arrester for a chemical tank or an end-of-line deflagration arrestor for a storage tank vent, Storagetech has a solution to safeguard your operations. Read on to learn how our flame arrestors can enhance safety and compliance in your facility, and how Storagetech competes head-to-head with industry leaders in quality and innovation.

What Is a Flame Arrestor?

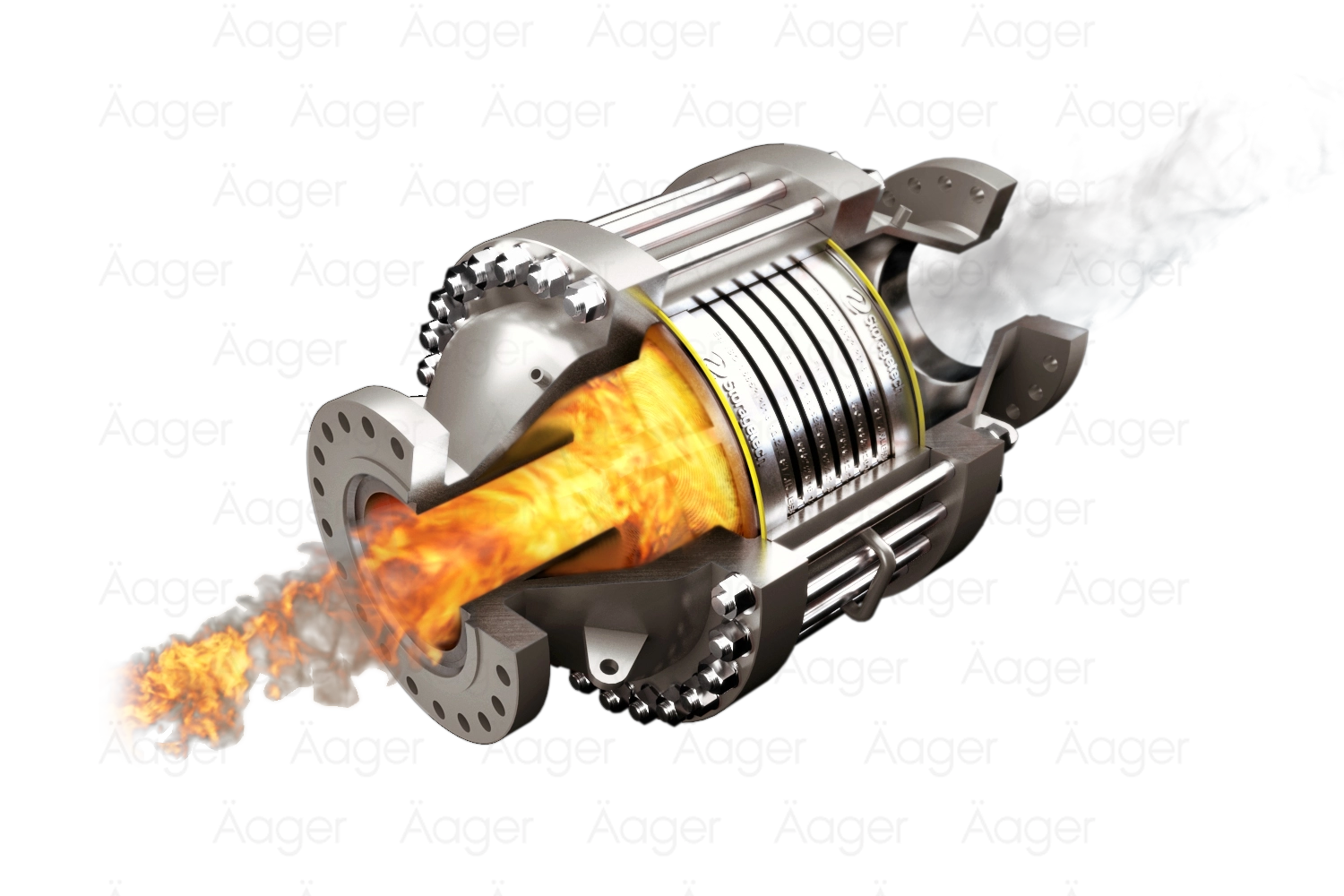

A flame arrestor (or flame arrester, sometimes called a flame trap) is a passive safety device that allows the free flow of gases or vapors under normal conditions while preventing the passage of flames or explosions. In simple terms, it’s a barrier that stops fire from traveling through piping or vent systems. Flame arrestors achieve this by quenching the flame front in a network of small channels or openings inside the device, absorbing the heat and dropping the gas temperature below its ignition point. The result is that flames cannot propagate beyond the flame arrestor, protecting the downstream side (the “protected” side) from ignition.

In practical use, flame arrestors are typically installed on openings of tanks or within pipelines that handle flammable gases or liquids. For example, a flame arrestor might be mounted on a storage tank vent outlet or in a gas processing line. Under normal conditions, vapor flows through the device unrestricted. However, if an ignition occurs either inside or outside the system, the flame arrestor’s internal element (often made of crimped metal ribbons or mesh) will cool and extinguish the flame by absorbing its heat energy. This prevents the fire from spreading into the tank or further down the line. Essentially, the flame arrestor sacrifices the flame by dissipating its heat on a high surface-area element, so the gases emerging on the other side are too cool to ignite.

Key purposes of flame arrestors include: preventing explosions from entering or escaping equipment, protecting personnel and assets from fire damage, and ensuring compliance with safety regulations. In industries like oil and gas, chemical manufacturing, petrochemicals, and distilleries where flammable vapors are handled routinely, flame arrestors serve as an essential line of defense against catastrophic incidents. By stopping flame propagation, they help avoid chain-reaction explosions that could devastate facilities and endanger lives. Regulatory bodies often mandate flame arrestors in certain applications as well – for instance, environmental and safety standards (like NFPA 69 and EN ISO 16852) require flame arrestors on specific vent lines to prevent flashback ignition of vapors. In summary, a flame arrestor is a critical safety device that “will interrupt or prevent the passage of flame” while letting flammable gas mixtures flow, thereby safeguarding industrial processes from fire and explosion hazards.

How Does a Flame Arrestor Work?

Flame arrestors work on the principle of flame quenching in narrow passages. When a flame front reaches the flame arrestor element, the device’s internal passages (made of heat-conductive metal) absorb the flame’s heat and reduce the temperature of the gas below its ignition pointen. This stops the combustion process. The design of the flame cell element is crucial – it provides a tortuous path for gases, meaning the flame must travel through many small channels or pores, each extracting heat from the flame. By the time the flame front attempts to emerge on the protected side, it has lost sufficient heat such that it cannot continue burning.

The effectiveness of a flame arrestor’s element is often characterized by the MESG (Maximum Experimental Safe Gap) of the gas – basically the largest gap between plates that will prevent ignition of that gas. Flame arrestors are engineered with channels smaller than the MESG for the specific vapor being. For instance, a flame arrestor for a highly explosive gas (like hydrogen) will have very tight, fine passages, whereas one for a less volatile vapor can use slightly larger channels. Smaller gap = more quenching power, but also creates more pressure drop in flow; larger gap = less pressure drop, but less quenching. Manufacturers carefully design flame arrestor elements to balance safety and flow efficiency. Storagetech uses advanced crimped metal ribbon and reverse winding technologies in our flame cells to maximize the quenching effect without unduly restricting flow.

When a flame arrestor is in place, normal operation is unaffected – gases vent or flow freely through the device. If an ignition occurs on the unprotected side (for example, an external fire near a tank vent or a spark in a pipe), the flame arrestor will immediately cool and extinguish the incoming flame front as it attempts to travel through the element. The downstream side remains safe, as only cooled combustion products pass through. This action happens in milliseconds. Flame arrestors are passive devices with no moving parts, which makes them inherently reliable – they are always “on guard” to stop a flashback flame.

It’s important to note that flame arrestors are generally uni-directional or bi-directional depending on design. Many in-line flame arrestors are bi-directional, meaning they can stop a flame coming from either direction in the piping. End-of-line arrestors naturally only face one direction of potential flame (outside coming in). In Storagetech’s flame arrestors, the robust symmetric design often provides protection in both directions, adding an extra layer of safety in dynamic systems.

Maintenance is another aspect of how flame arrestors work over time. Because arrestor elements can become fouled (e.g., by soot, resin, or corrosion), regular inspection and cleaning is needed to ensure the small channels remain open. Storagetech addresses this by offering highly maintenance-friendly designs – our arrestor elements are durable and protected during handling, and easy to remove and reinstall for inspection. For example, our Model 300 in-line flame arrestor features a robust flame cell element that is easy to remove, clean, and reassemble, ensuring that maintenance downtime is minimized. Additionally, a quality flame arrestor must withstand the mechanical and thermal stress of a halted ignition. Storagetech flame arrestors are built with heavy-duty casings (carbon steel, stainless steel, or special alloys) that can endure the pressure of a stopped flame front or even an explosion shock, all while keeping the flame quenched.

In summary, a flame arrestor works by acting as a heat sink for a flame: it lets gas flow normally but catches and cools any flame trying to pass through. This simple concept – flame quenching by heat absorption – is what allows flame arrestors to protect equipment like tanks, reactors, and pipelines from igniting each other. Next, we’ll look at the different types of flame arrestors available and how each type is used for specific scenarios (deflagration vs. detonation, in-line vs. end-of-line, etc.).

Types of Flame Arrestors

Industrial flame arrestors come in several designs and configurations, each suited to particular applications and flame conditions. The main types of flame arrestors include:

-

End-of-Line Flame Arrestors (Deflagration Arresters)

-

In-Line Flame Arrestors (Deflagration or Detonation Arresters)

-

Detonation Flame Arrestors (a specialized in-line type)

-

Deflagration vs. Detonation Rated Arrestors (by flame speed rating)

-

Special Combination Arrestors (e.g., flame arrestor integrated with vents or valves)

Let’s explore each type in detail:

End-of-Line Flame Arrestors (Vent Flame Arresters)

End-of-line flame arrestors are installed at the end of a vent pipe or on tank outlets that vent to atmosphere. They are designed to stop flames propagating into or out of a vessel from an external ignition. Typically, these arrestors protect against atmospheric deflagrations – which are subsonic flames (relatively slower burn). For example, on a storage tank vent, an end-of-line arrestor will prevent a fire outside (like a lightning-induced ignition of vapor) from flashback into the tank. They act as a flame barrier on the tank’s breather vent.

Storagetech’s end-of-line flame arrestors are often used on tank farm vents, gas meter stations, and industrial process vents where the concern is an external flame source. These devices usually mount vertically on the vent outlet. Many end-of-line models also incorporate weather hoods or automatic opening covers to protect the flame element from rain/debris while still allowing pressure venting. For instance, our Model 312 is an end-of-line deflagration flame arrestor with an automatic opening hood for pressure release. End-of-line units are generally deflagration arresters only (not intended to stop high-pressure detonations) because one side is open to atmosphere – the flame velocity from an open atmosphere ignition is typically subsonic.

Key features of end-of-line flame arrestors include: a wide flame arrester element (usually a single element or stack of elements) sized to handle continuous venting, and the ability to withstand endurance burning. Endurance burn means if the flame arrestor is subjected to continuous burning on the face (e.g. a fireball on the vent outlet), it can withstand that heat for a rated duration without failing. Storagetech’s end-of-line arrestors are endurance burn tested and certified per EN ISO 16852 for safe use on tank vents. Many models also double as vent caps or include pressure/vacuum relief functionality, serving dual purposes on storage tanks.

In-Line Flame Arrestors

In-line flame arrestors are installed within piping systems (inline with the pipe) to prevent flames from traveling through the pipe network. They are commonly used when flammable gases or vapors are being transported in pipes, and an ignition could occur somewhere in the system. An in-line flame arrestor could be placed, for example, at a distance down a vapor line to stop a flame front from moving further along. Depending on the application, in-line arrestors can be designed for deflagration conditions (low-speed flame fronts) or for the more severe detonation conditions (high-speed, pressure wave-induced flames). We’ll discuss detonation types next.

Storagetech offers both vertical and horizontal in-line flame arrestors to accommodate different piping layouts (our models 300 and 301 series, for instance, cover vertical and horizontal deflagration arresters). In-line arrestors have flanged or threaded connections that match the pipeline and are typically bi-directional. They contain one or more flame element cartridges inside a robust housing. Because in-line units are used where flames might originate internally (from either direction), they are often built to a higher standard of shock resistance. For short pipeline runs or near a potential ignition source, an in-line deflagration flame arrestor may suffice – these are rated to stop a flame front in the early stages of an explosion (subsonic flame speeds). However, if there is a chance for the flame to accelerate (longer run-up distance or turbulence that could create a detonation), a detonation-rated arrestor is necessary.

In-line flame arrestors are used widely in chemical plant piping, gas distribution lines, vapor recovery units, and processing facilities. They ensure that if a fire starts in one part of the process (say a reactor or a flare stack), it doesn’t travel upstream or downstream to other equipment. One common use is in biogas or vapor recovery systems: placing in-line arrestors on lines carrying biogas to flares or generators to prevent flashback. Another use is on loading/unloading lines in terminals – an inline arrestor can stop flames in piping between a storage tank and a transport vessel. Storagetech’s in-line models are built with minimal pressure drop design (our flame cells provide roughly 30% less pressure drop compared to conventional designs by extending the flame path without overly constricting flow. This means you get safety without sacrificing operational efficiency – important for processes that require steady gas flow.

Detonation Flame Arrestors

Detonation flame arrestors are a specialized subset of in-line arrestors, engineered to stop detonations – which are explosions where the flame front travels at supersonic velocity, coupled with a shock wave. Detonations create much higher pressures and flame speeds than deflagrations, so detonation arrestors must be extremely robust. They typically have a stronger housing, and often a multi-element design or a longer quenching path to absorb the greater energy of a detonation. Detonation arresters are used in situations with a risk of long-run piping explosions or where the flame could accelerate (for instance, vapor recovery systems with long pipelines, or high-flow vents where turbulence can speed up a flame).

A true detonation flame arrester is built to withstand both stable and unstable detonations. Stable detonation is the sustained high-speed combustion once the detonation wave has fully developed, while unstable (or overdriven) detonation refers to the initial irregular phase which can be even more violent. It’s critical that a detonation arrestor handle the worst-case scenario – an unstable detonation – because if it only handles a stable detonation, a more energetic explosion could destroy it. Storagetech’s detonation arrestors are tested for the full spectrum of detonation pressures, ensuring they’ll stop the flame even in the most extreme conditions. As one industry source notes, “All Groth detonation flame arresters are designed to withstand both stable and unstable detonations.”Storagetech follows the same philosophy of robust design for maximum protection.

Detonation arrestors are often a requirement in marine loading terminals, refinery vapor recovery units, and large fuel storage farms where regulations demand detonation-proof safety devices. For example, in the United States, Coast Guard regulations require detonation flame arresters in vapor control systems for marine transfer of oil or hazardous materials. These arresters are placed at specific points in the piping (per standards like 33 CFR 154) to ensure any ignition in the vapor line is contained. Storagetech’s Model 320/321 series are detonation flame arrestors (vertical and horizontal in-line, respectively) designed for Explosion Groups IIA and IIB vapors – meaning they can stop detonations of gases in those categories. We also engineer detonation arrestors for bi-directional flow, so no matter which side a detonation comes from, the flame is arrested.

One hallmark of detonation flame arrestors is that they are often built to larger sizes and higher pressure ratings, to accommodate large flow systems like main product lines or vapor headers. Storagetech has the capability to produce detonation arresters at very large diameters – for instance, we recently delivered a 30″ (DN 750) inline detonation flame arrestor for a natural gas storage facility. This huge flame arrester, made of stainless steel and built to ASME Section VIII Div.1 code, is designed and certified according to EN ISO 16852:2016 standards. It’s rated for Group IIB methane gas detonation and exemplifies our commitment to pushing the boundaries of flame arrestor technology. Few manufacturers worldwide can supply such large detonation arresters, highlighting Storagetech’s engineering prowess.

In summary, choose a detonation flame arrestor when your scenario involves potential high-speed explosions or when codes and risk analyses indicate a detonation risk. They offer the highest level of protection, albeit usually at a higher cost and slightly higher pressure drop due to their beefier construction. If in doubt, it’s safer to err on the side of using a detonation arrester, as it will also stop deflagrations – the reverse is not true (a deflagration-only unit may fail if a detonation occurs.

Deflagration vs. Detonation Arresters: Understanding the Difference

It’s important to understand the terms deflagration and detonation as they pertain to flame arrestors, because these define what the arrestor is capable of stopping:

-

A Deflagration is a flame that propagates at subsonic speeds (slower than the speed of sound) and with a relatively lower pressure wave. Most ordinary fires and low-speed burn scenarios are deflagrations. In a pipeline or vent, a deflagration is often what you get if the flame has a short distance to travel or is in open air – the flame speed might be on the order of meters per second to tens of m/s, and pressures are moderate. Deflagration arresters are designed to stop these flames. They are often installed near tank vents or at the end of lines, where the flame hasn’t had distance to accelerate. According to Storagetech technical guidance, deflagration flame arresters act as a barrier that “stops the propagation of a flame and dissipates the heat of the flame below the auto-ignition temperature of the vapor”, effectively preventing flashback. End-of-line and inline deflagration arrestors typically can also withstand a stabilized flame on one side for a certain period (e.g., 30 minutes of continuous burning) without letting it flash through.

-

A Detonation is a combustion wave that has transitioned to supersonic speed, usually due to confinement and turbulence. Detonations generate a shock wave ahead of them and have much higher pressures. In piping, a deflagration can transition to a detonation if the run length is long enough or obstacles/turbulence in the pipe cause flame acceleration. Detonations are extremely destructive if not stopped. Detonation arresters are built to quench these supersonic flames and absorb the shock. They are tested to ensure that even if a flame accelerates to a detonation, the device will stop it and not rupture. Storagetech detonation arresters are designed to “quench a detonation or deflagration traveling down the pipeline and prevent it from spreading to other areas”, and are built to handle the higher pressures (often they can withstand explosion pressures of several dozen bar). They are also rated for longer endurance burns (e.g., 120 minutes of flame stabilization) since detonations may involve more sustained burning of gases.

When selecting flame arrestors, understanding whether you need deflagration or detonation protection is crucial. Deflagration arresters are sufficient for many vent and short-run applications, whereas detonation arresters are required for long runs or where regulations dictate. If unsure, consult with Storagetech’s experts – our team can evaluate factors like pipe length, diameter, gas properties, and potential ignition energy to determine the appropriate type. (See the section Choosing the Right Flame Arrestor below for more guidance on this decision.)

Special Combination & Integrated Flame Arrestors

In addition to the basic types above, Storagetech also offers integrated flame arrestor solutions that combine multiple functions. One example is our Pressure/Vacuum Relief Valve with Flame Arrestor (models 330/331 series). These units serve dual purposes: they act as a breather valve (maintaining tank pressure by relieving or vacuum-breaking as needed) and also contain a built-in flame arrestor element to stop any external flame. Such combination devices are popular on storage tanks – they ensure the tank is both pressure-protected and flame-protected in one assembly. This reduces the number of fittings on the tank and ensures comprehensive safety (overpressure protection plus explosion protection).

Another special type is the inline flame arrestor with WECO connections (quick couplings) which Storagetech produces for certain oilfield or loading applications. These allow rapid connection/disconnection on truck or rail loading lines while still providing flame arrestor protection. There are also offset or angled flame arrestors designed to fit into tight pipework layouts (Storagetech can custom-engineer flame arresters to fit spatial constraints without sacrificing performance).

For certain chemically sensitive environments, we provide flame arrestors with special coatings (e.g., PTFE coating) to resist corrosion or polymer buildup on the flame element. This is especially useful in industries where vapors might cause deposits (e.g., certain monomers that could polymerize). The PTFE or other coating helps keep the element functioning longer between cleanings and protects against weather or acidic gases.

Lastly, there are liquid seal flame arrestors (not in Storagetech’s core lineup, but worth mentioning) which use a liquid bath to quench flames. These are often used on very large vents or for certain low-pressure systems. However, they are maintenance-intensive (need to keep liquid at proper level) and have been largely supplanted by dry flame arrestors like those Storagetech offers.

Summary of Flame Arrestor Types:

-

End-of-Line Arrestors: For tank vents and exhausts; stop atmospheric deflagrations from entering; often integrated with vent caps or P/V valves; endurance burn capable.

-

In-Line Deflagration Arrestors: For short runs in pipes; protect against deflagrations in piping; install near potential ignition points or branch intersections.

-

In-Line Detonation Arrestors: For long or complex pipe systems; stop stable and unstable detonations; heavier-duty construction; required by code in many vapor control systems.

-

Bi-directional (Dual) Arrestors: Designed to stop flame from either side (common in inline designs).

-

Integrated Units: Flame arrestors combined with valves or vents for multi-function safety (common on storage tank equipment).

Storagetech’s flame arrestor product range covers all these types, ensuring we have the right solution for each application. Our models are available in sizes from 2″ (~50 mm) up to 30″ (~750 mm) and beyond, in various materials (carbon steel, SS304/316, aluminum, Hastelloy, etc.) to handle different chemicals and environments. All designs are tested according to international standards and certified for use in relevant explosion hazard zones.

Applications by Industry: Where Flame Arrestors Are Used

Flame arrestors are utilized across a wide spectrum of industries wherever flammable gases or vapors are present and there’s a risk of ignition. Below we outline major industries and scenarios, highlighting how flame arrestors are applied in each:

Oil & Gas Industry (Upstream, Midstream, Downstream)

Oil and Gas operations handle highly flammable hydrocarbons at all stages – from extraction (upstream) to transportation/storage (midstream) to refining (downstream). The risk of fire or explosion is ever-present, so flame arrestors are essential components of the safety systems in this industry.

-

Storage Tanks and Tank Farms: Crude oil tanks, fuel storage tanks, and other hydrocarbon storage vessels are typically fitted with end-of-line flame arrestors on their vent openings. During normal operations (breathing, filling, emptying), these vents allow vapor to escape or enter to balance pressure. A flame arrestor on the vent ensures that if there’s an external fire or lightning strike igniting the vented vapors, the flame will not travel into the tank. This is crucial especially when vapor emissions are high (for example, during loading). Storagetech flame arrestors protect bulk storage facilities by sitting atop each tank vent or integrated into pressure-vacuum valves, blocking any external flame ingress.

-

Process Vessels and Refinery Units: In refineries and gas processing plants, there are numerous potential ignition sources and flammable streams. Flame arrestors are used on process unit vents (e.g., vacuum distillation columns, gas separators) to prevent flashback through vent lines. They are also installed on knock-out drum vents, vapor recovery units, and flare headers. A common application is at the base of flare stacks: before gases enter the flare, a detonation arrestor is placed to stop any flashback from the flare flame into the facility. Additionally, refinery vapor recovery systems (which capture vapors from loading operations to comply with environmental rules) often have detonation flame arrestors because the vapor lines can be long and subject to detonations.

-

Pipelines and Transfer Lines: Midstream pipelines carrying natural gas or oil vapors sometimes incorporate inline flame arrestors, particularly at transfer terminals or compressor stations. For instance, when loading tanks onto barges or trucks, inline flame arrestors may be fitted in the loading arm or hose to catch any ignition that might occur in the line (due to static or other sources). Offshore platforms, which fall under both oil & gas and marine, also utilize flame arrestors on ventilation outlets and gas piping to meet safety regulations (offshore rules often mirror the USCG requirements for flame arrestors on any vent connected to flammable storage).

-

Upstream (Drilling/Production): At oilfield production sites, flame arrestors can be found on treaters, separators, and storage tanks at well sites (commonly known as heater-treaters or gun barrel tanks that separate oil/gas/water). The vent stacks of these are equipped with flame arrestors to prevent any external flame from igniting the tank vapor space. Also, if vapor recovery units (VRUs) are used at well sites to capture gas, those VRU lines will have flame arrestors for safety.

In summary, the oil & gas industry relies on flame arrestors for tank vent protection, pipeline flashback prevention, and equipment safety. Installing flame arrestors helps companies meet safety standards (API, OSHA, etc.) and avoid devastating accidents. Storagetech’s flame arrestors in this sector are built to oilfield toughness – for example, our 30″ detonation arrestor for a natural gas pipeline showcases how we support even the largest scale operations. We also offer quick delivery and custom designs to fit existing oilfield infrastructure, ensuring minimal disruption when upgrading safety systems.

Chemical and Petrochemical Industry

The chemical processing and petrochemical industries deal with a vast range of flammable chemicals – from solvents and monomers to finished chemical products. These facilities often have complex piping networks, reactors, and storage systems where explosive vapors are present. Flame arrestors are indispensable in preventing process fires from spreading.

-

Chemical Storage Tanks: Similar to oil tanks, chemical storage vessels (for solvents, alcohols, monomers, etc.) use end-of-line flame arrestors on vent connections. For example, a tank of toluene or ethanol in a chemical plant will have a vent outfitted with a flame arrestor to stop any external flame. This is especially vital if the tank’s relief devices vent vapors during upset conditions. Storagetech flame arrestors are commonly used by chemical plants to protect VOC storage tanks, ensuring compliance with standards like NFPA and API recommendations for tank safety.

-

Process Piping and Units: In chemical plants, flammable gases often flow between units (e.g., between a reactor and a condenser, or between a distillation column and a storage tank). Flame arrestors are strategically placed in these pipelines to isolate sections of the plant. For instance, an inline flame arrester for a chemical tank line might be installed where a pipe from a reactor feeds into a storage tank – to prevent any flame in the tank or reactor from moving into the other. As another example, consider a distillation column handling hexane: a flame arrestor on the column’s overhead vent or reflux line can stop an external flame or a fire from propagating into the column.

-

Vapor Recovery and Emission Control: Petrochemical facilities often use vapor recovery systems (VRUs) to capture emissions of flammable gases. These systems, by design, concentrate flammable vapors and often route them to a control device (like a flare or incinerator). Flame arrestors (usually detonation type) are installed in the VRU lines and at the inlet of the control device to ensure a flame doesn’t flash back into the VRU or storage tanks. This is not only a safety measure but also required by environmental regulations – e.g., the Clean Air Act mandates safety measures in vapor combustion systems, which include flame arrestors as highlighted in detonation arrester use cases.

-

Chemical Reactor Vents: Many reactors in chemical production (and also in pharma, discussed later) have vents or relief systems for pressure control. If those vents release flammable gases, a flame arrestor is installed to prevent external ignition sources from causing a reactor explosion. For example, a polymerization reactor producing polyethylene might vent ethylene – a flame arrestor on that vent is critical. Storagetech’s flame arrestors are designed to handle such continuous processes, with low pressure drop so as not to impede reactor venting while still blocking any flame intrusion.

Materials of construction are an important consideration in chemical industries. Storagetech supplies corrosion-resistant flame arrestors (e.g., stainless steel, Hastelloy) for aggressive chemical environments. We ensure that the flame arrestor materials are compatible with the chemicals in your process to maintain both safety and chemical integrity. Our devices meet ISO 16852 and NFPA 69 standards which are commonly referenced in the chemical industry for flame arrester performance.

Pharmaceutical Industry

The pharmaceutical industry may not seem as obvious a candidate for flame arrestors, but many pharma manufacturing processes involve flammable solvents (like ethanol, acetone, isopropanol) and reactions that produce flammable gases. Safety and purity are paramount, so flame arrestors are used to prevent fires and also to maintain clean conditions (since a flame event could ruin a batch and contaminate equipment).

-

Solvent Storage and Recovery: Pharma plants often have solvent storage tanks and solvent recovery systems (for recycling expensive solvents). These systems concentrate flammable vapors. Flame arrestors are installed on vent lines and exhaust ports of solvent recovery units to stop any ignition from entering the system. For instance, a solvent recovery still that captures ethanol vapors from a process will vent non-condensed vapors; a flame arrestor ensures no external spark ignites those vapors in the still. This protects both the process and the product purity.

-

Reactors and Process Vessels: Pharmaceutical reactors (for synthesizing active ingredients) can produce or handle flammable gases. For example, hydrogenation reactors (common in pharma for adding hydrogen to molecules) have hydrogen – which is very flammable – in them. A flame arrestor on the reactor’s vent or relief device will prevent any flame from getting into the reactor headspace. This is crucial not just for safety but to avoid an explosion that could scatter product and lead to contamination. Similarly, dryer equipment or vacuum ovens that handle solvents may have flame arrestors on their vacuum lines if there’s a chance of ignition.

-

Facility Utilities (Biogas & HVAC): Some pharma facilities treat waste biologically (generating biogas) or use boilers that produce flammable mixtures. Flame arrestors can appear on small biogas digesters or waste treatment units within pharma plants, as well as on ventilation lines if handling any anesthetic or flammable gases.

Pharmaceutical applications often require stainless steel flame arrestors to meet hygienic standards and avoid contamination (no paint flakes, etc.). Storagetech provides flame arrestors in sanitary designs when needed, and our materials (SS316L, etc.) ensure compliance with cGMP and FDA guidelines for incidental contact. Additionally, pharma companies appreciate low pressure drop designs (to avoid affecting delicate reactions) and high efficiency arrestors. Storagetech flame arrestors deliver on these needs by combining safety with process integrity – keeping your facility safe without impacting product yield or quality.

Storage Terminals & Tank Farms

Storage terminals (for fuel, chemicals, etc.) and tank farms deserve a special mention even though they are part of oil, gas, and chemical industries, because flame arrestors are so critical in these settings. A tank farm is a collection of tanks storing flammable liquids (like a fuel depot or a chemical warehouse facility). Here’s how flame arrestors are applied:

-

Tank Vent Protection: Every atmospheric storage tank containing Class I flammable liquids (gasoline, ethanol, solvents, crude, etc.) should have a flame arrester on any open vent. Often, these are in the form of a combined pressure-vacuum vent and flame arrestor. Storagetech’s integrated flame arrester P/V valves (e.g., model 331) are popular in tank farms to reduce emissions and protect against flame ingress simultaneously. If separate devices are used, an end-of-line flame arrestor is mounted just outside the breather valve. This setup stops external fire from entering, as described earlier.

-

Manifold and Loading Lines: Terminals have piping manifolds to receive or deliver liquids. If vapors from multiple tanks are manifolded together for vapor recovery during truck or ship loading, detonation arrestors are placed on these vapor lines to isolate tanks from each other in case of a flash (so a flame in one tank’s vent line doesn’t jump into others via the common line). Additionally, truck loading racks might have flame arrestors on vapor return hoses and marine loading arms (ships loading at docks often connect a vapor return line to shore; regulations require flame arrestors on these connections due to the possibility of flame in the ship’s tanks or shore system). In fact, international maritime rules (e.g., the IMO and US Coast Guard) mandate flame arrestors on cargo tank vent systems for tankers – this is a marine application overlapping with storage terminals.

-

Emergency Vent & Flame Arrestor Combos: Tank farms also have emergency venting (for fire exposure scenarios). Storagetech offers solutions where a flame arrestor is fitted under a spring-loaded emergency relief valve or gauge hatch, so that even during emergency venting, a flame cannot blow into the tank. This is an advanced application ensuring that if a tank is venting vapors rapidly due to an external fire (worst case scenario), flames from outside are still blocked. Our engineering team can guide on how to incorporate flame arrestors with emergency relief vents and gauge hatches for a fully protected tank system (see our Emergency Relief Valves & Gauge Hatches for complementary solutions).

Overall, storage terminals rely on flame arrestors for regulatory compliance (e.g., EPA and local fire codes require them) and for insurance and safety best practices. A single tank fire can escalate to a massive blaze if not contained – flame arrestors ensure that a fire at one vent does not spread to the tank’s contents or neighboring tanks. Storagetech’s presence in many tank farms around the world as a flame arrester supplier underscores our reliability in this field. Our devices are often chosen for retrofit upgrades at older terminals to improve safety, thanks to easy customization to existing flanges and proven certification.

Marine & Offshore (Shipboard and Coastal Facilities)

The marine industry encompasses oil tankers, chemical carriers, FPSOs (floating production storage units), as well as offshore platforms and coastal facilities handling flammable fluids. Flame arrestors play a key role in maritime safety:

-

Marine Tankers (Ships): Cargo ships carrying oil or chemicals have vents (often called P/V valves with flame screens) on each tank. International regulations (IMO, SOLAS, and national regs like USCG rules) require flame arrestors or flame screens on these vents to prevent flames from igniting tank vapors. For example, the US Coast Guard stipulates that any vessel transferring flammable cargo have detonation-proof flame arresters in the vapor lines. Storagetech flame arrestors can be found on marine applications such as the vent outlets of tanker ships and barge vents. We provide end-of-line deflagration arrestors for vent masts and detonation arrestors for vapor recovery connections used when loading/unloading ships. These ensure compliance with standards like 33 CFR 154 (for US marine terminals) and IMO’s International Gas Carrier (IGC) Code for onboard safety.

-

Offshore Platforms: Oil & gas offshore platforms utilize flame arrestors on equipment like gas venting systems, storage vessel vents, and flare systems. For instance, an offshore oil rig will have flashback arrestors on lines leading to the flare boom to prevent any flashback from the flare flame. Also, any enclosed vent from process equipment that releases to the atmosphere typically has an arrestor to prevent external platform fires from getting into the equipment. Offshore units deal with confined spaces and high consequences for fires, hence detonation arrestors are often used as a precaution given the confined nature of process skids. Storagetech’s robust stainless steel flame arrestors are well-suited for the corrosive marine environment, with options for exotic alloys if needed to resist salt air and H₂S-laden gases common offshore.

-

LNG/LPG Facilities: While LNG (liquefied natural gas) itself is not stored as a vapor, the boil-off gas in LNG tanks and LPG (liquefied petroleum gas) storage do involve flammable vapors. Marine import/export terminals for LNG/LPG use flame arrestors on their vapor handling lines. Moreover, bunker fuel systems (fueling ships with heavy fuel oil or now LNG) will employ flame arrestors on vent lines and sometimes in fuel lines to engines (in case of backfire).

-

Marine Fuel Handling: Even outside of ships, consider marinas or fuel docks – the venting systems for fuel storage at ports have flame arrestors by law. A small marina gasoline tank, for example, might have a simple flame screen on its vent pipe to stop flames. Storagetech provides solutions scalable from small vent flame arrestors to large terminal ones, so we cover marine needs from small harbor tanks to supertanker terminals.

Using flame arrestors in marine contexts is not just best practice but often a legal requirement. This is underscored by rules such as “United States Coast Guard regulations require installation of flame arresters (suitable to interrupt a detonation) in vapor control piping” for marine transfer facilities. Safety at sea is paramount, and flame arrestors are one of the unsung heroes ensuring that a fire doesn’t lead to a catastrophic ship or platform loss.

Water Treatment, Biogas & Sewage

Flame arrestors find important use in water and wastewater treatment facilities, primarily because of the generation of biogas (methane) from anaerobic digestion and the handling of other flammable gases (like digester gas or landfill gas). Additionally, in sewage systems, methane can accumulate in pipes, posing explosion risks.

-

Biogas Digesters: Wastewater treatment plants often have anaerobic digesters that produce biogas (methane + CO₂). This biogas is captured and either flared or used as fuel. Flame arrestors are installed on the digester gas lines – typically on the lines from digesters to gas storage or to the flare. They ensure that if the flare has a flame flashback or if any ignition occurs in the gas handling system, it won’t travel back into the digester tank (which could be disastrous, as digesters are large and full of gas). End-of-line deflagration arrestors are used on digester roof vents as well, to prevent external flames from entering the digester gas space.

-

Landfill Gas Systems: Similar to biogas, landfills produce methane. Collection systems funnel this gas to flares or generators. Flame arrestors (often detonation type due to long runs of piping in a landfill field) are placed at strategic points to isolate sections and to protect the main flare or compressor. In one case, detonation arrestors might be installed at the main header from multiple wells and at the flare stack base. This prevents any fire from propagating through the spiderweb of collection pipes across the landfill.

-

Sewage Collection and Pumping Stations: Sewer gases can be rich in methane and hydrogen sulfide. Where sewage lines are vented or at pumping station wet wells, flame arrestors can be fitted on vents to stop external flames or lightning-induced ignitions. Some regulations require them in sewer systems near industrial facilities.

-

Biogas Power Generators: When biogas is used to fuel engines or turbines, flame arrestors are installed on the intake lines to the engines (in case of backfire in the engine intake manifold). These arrestors are usually deflagration type since the volume is small and near the source. Storagetech flame arrestors help safeguard biogas gensets by containing any backfire to the engine itself.

In water treatment settings, corrosion resistance is key because of moisture and H₂S content. Storagetech offers aluminum or stainless steel flame arrestors with special coatings for these applications. We ensure compliance with relevant standards (for example, EN 12874 is a European standard specifically for flame arrestors in things like gasoline vapor recovery and likely referenced for certain sewage applications). Our flame arrestors are used in many municipal projects – an example being a large wastewater facility where our in-line detonation arrestors provide safe operation of a biogas upgrade plant.

Food & Beverage (Distilleries and Breweries)

In the food and beverage industry, particularly in alcohol production (breweries, distilleries, bioethanol plants), flammable vapors are generated as part of fermentation and distillation. While this may not be as obvious as in chemical plants, flame arrestors are indeed used to prevent fires in these processes:

-

Fermentation Tanks: During fermentation (beer brewing, bioethanol fermentation, etc.), CO₂ is produced along with ethanol vapors (in trace amounts). Typically fermentation tanks are vented. In large distilleries, the ethanol vapor concentration can be significant and flammable. Flame arrestors are installed on fermentation tank vents to stop any external ignition from igniting the ethanol vapor above the brew. Breweries often call these flame screens on fermentation vats. This protects the product and facility, especially since fermentation areas can have multiple ignition sources (e.g., electrical equipment).

-

Distillation Columns and Stills: Distillation of spirits (whiskey, vodka, etc.) or industrial alcohol involves boiling alcohol, which releases a lot of vapor. Stills have vents/relief valves and connected condensers. Flame arrestors on these vents or between the still and condenser ensure that a fire in the vapor space doesn’t flash back into the still pot. Remember, distilleries are essentially processing high-proof alcohol – very flammable. Historically, distillery explosions have occurred due to vapor ignitions, so modern facilities incorporate flame arrestors as a preventive measure.

-

Storage of Ethanol/Fuels: Many breweries and distilleries also produce biofuel or have ethanol byproducts, which are stored in tanks. Those storage tanks use flame arrestors just like any chemical storage would.

The food & beverage industry tends to be cautious about introducing any device that could contaminate the product. Storagetech addresses this by providing flame arrestors that do not shed particles and are made of food-grade materials (stainless steel). We’ve supplied flame arrestors to distilleries where the unit had to be polished stainless and meet hygienic standards. Additionally, our low-pressure-drop designs help in these industries because fermentation and distillation rely on slight pressure differentials – a high pressure drop could disrupt the process yield. By incorporating flame arrestors, producers ensure safety without compromising the quality or efficiency of production.

Other Industries and Applications

Beyond the ones detailed above, flame arrestors are also critical in power generation (gas-fired power plants have flame arrestors on fuel lines and vent lines), mining (coal mine ventilation systems historically used flame arrestors like Davy lamps and modern methane drainage systems may include them), pulp and paper (they produce turpentine and other flammable gases in process digesters), and any industrial scenario dealing with flammable gases. Even hydrogen fueling stations and battery energy storage systems (which emit hydrogen) are starting to use flame arrestors as an added safety measure to stop flashbacks in vent lines.

In summary, wherever there is a combination of flammable atmosphere + possible ignition source + a pathway for fire, a flame arrestor finds its use. It is a versatile safety solution deployed from large petrochemical complexes down to small industrial setups. Storagetech, having served clients across 60+ countries, has experience in tailoring flame arrestor solutions to virtually every industry scenario – from desert oil fields to offshore rigs, from underground mines to pharmaceutical labs.

Choosing the Right Flame Arrestor (Buyer’s Guide)

Selecting the appropriate flame arrestor for your application is crucial to ensure safety and compliance. The “right” flame arrestor depends on several factors. Below is a buyer’s guide with key considerations and technical criteria to help you make an informed decision:

1. Deflagration vs. Detonation Risk: Determine whether your system requires a deflagration arrestor or a detonation arrestor. This depends on the potential flame speed and pressure. Ask questions like: How long are the vapor paths? Could a flame accelerate to detonation in this system? If you have long pipelines or highly reactive gases, lean toward detonation arresters. If the arrestor is at an atmospheric tank vent or very near an ignition source, a deflagration arrestor may suffice. Remember, detonation arrestors can stop deflagrations as well, so when in doubt or if regulations mandate, choose detonation-rated for an added safety margin. Storagetech can provide guidance based on your piping layout (for example, a rule of thumb is if run-up length to the arrestor is more than ~50 pipe diameters, consider detonation type).

2. Location of Installation (End-of-line or In-line): Decide if the arrestor will be installed at the end of a line (venting to atmosphere) or in-line (between pieces of equipment). End-of-line flame arrestors are typically deflagration-only and are designed with weatherhoods and endurance burn capability – ideal for tank vents and exhausts. In-line arrestors come in deflagration and detonation types and must match the pipe size and rating of your system. Also consider orientation (vertical vs horizontal) based on where you plan to install; Storagetech offers both configurations.

3. Gas/Vapor Properties (Explosion Group & MESG): Identify the gas or vapor the flame arrestor will protect. Gases are classified into explosion groups (IIA, IIB, IIC in ATEX classification, for example) based on their flammability and MESG. The flame arrester you choose must be certified for the gas group of your vapor. For instance, hydrogen is Group IIC (very small MESG), requiring an arrestor rated for IIC. Many gasoline vapors are IIB, and some heavier vapors IIA. Storagetech flame arrestors are ATEX certified for groups IIA and IIB as standard, with special designs for IIC if needed. Always check the arrestor’s certification: a device for IIB may not stop an IIC gas flame. We provide the MESG or gas group data in our specs; ensure compatibility with your vapor.

4. Pipe Size and Flow Capacity: Flame arrestors must be sized appropriately for the flow in your system. Consider the connection size (diameter) – e.g., 2″, 4″, 8″, etc., and ensure the flame arrestor of that size can handle your maximum flow rate with acceptable pressure drop. Oversizing an arrestor can reduce pressure drop but may be costlier; undersizing can starve your process or create unsafe pressure build-up. Storagetech offers arrestors in a wide range of sizes (including custom large sizes) to fit your exact needs. We can provide flow vs pressure drop curves for our units – use these to verify that under normal venting or process flow, the backpressure is within your tolerances. Typically, low pressure drop designs (like Storagetech’s) enable you to use the same line size arrestor as your pipe, without bottlenecking flow. Our arrestors often achieve significantly lower pressure losses (around 30% less) than older generation designs, which can be a deciding factor if your process is sensitive.

5. Operating Pressure & Temperature: Check the operating pressure and temperature of the system at the arrestor location. Flame arrestors are usually rated for atmospheric or low pressures, but detonation arrestors especially might be needed in pressurized systems. If your line operates above atmospheric pressure, ensure the flame arrestor is designed for inline use at that pressure. Also, in high temperature processes, verify the arrestor’s element material can handle it (most standard ones are fine up to certain temperatures, but extreme heat might call for special construction). Storagetech can incorporate steam jackets or heating on arrestors if needed to prevent condensation or to handle heavy viscous vapors that could solidify.

6. Endurance Burn Requirements: Determine if the flame arrester needs an endurance burn rating. Endurance burn means withstanding a flame on the face for a specified time (e.g., 30 minutes or 2 hours). End-of-line arrestors on storage tanks typically must be endurance burn certified (per ISO 16852) for safety – you don’t want the arrestor to fail if it’s engulfed in flames during a fire scenario. Detonation arrestors inherently usually meet endurance burn for a period as part of their testing (often with continuous 5 or 10 minute burn plus detonation). If your application could see sustained flame (like a tank vent in a fire), pick an arrestor with the appropriate burn rating. Storagetech’s products are tested according to standards that include such rigorous burn tests.

7. Material Compatibility: Choose the right material of construction. Factors influencing this include the gas corrosiveness, the environment (marine/salty, acidic, etc.), and any cleanliness requirements. Carbon steel arrestors are economical and fine for many hydrocarbons, but in corrosive or moist environments, stainless steel is preferred to avoid rust that could clog the element. For coastal or marine installations, stainless or aluminum bronze materials resist salt corrosion. If the vapors are highly corrosive or the process demands it (e.g., in pharmaceuticals to avoid contamination), stainless steel or even higher alloys (Duplex SS, Monel, Hastelloy) might be needed. Storagetech flame arrestors can be supplied in SS316L, Duplex, Alloy 20, Hastelloy, Aluminum, etc., as well as with protective coatings (PTFE, epoxy) to suit your process. Always ensure gaskets and any internal materials (like element casing) are compatible too (we provide options like PTFE gaskets for chemical service).

8. Maintenance and Inspection: Consider how easy it is to maintain the flame arrestor. Some designs require full removal for inspection, others allow the element to be accessed in-line. Storagetech emphasizes easy maintenance – our arrestors have features like quick-release covers or element cartridges that can be taken out without removing the whole unit from the pipe. If your process is prone to fouling (e.g., polymerizing vapors, or sooty flame exposure), you’ll want an arrestor that can be cleaned frequently with minimal downtime. Also, check if spare elements or kits are readily available for the brand you choose. Storagetech provides spare flame cell elements and encourages users to keep a spare set, so one can be swapped during maintenance to reduce downtime.

9. Certification and Compliance: Ensure the flame arrestor has the necessary certifications for your project or region. Key ones include ATEX (for use in EU hazardous areas), ISO 16852 testing compliance, USCG Approval (for marine applications in the US), FM/UL (some North American certifications), and any local standards. Storagetech flame arrestors are ATEX-certified up to 18″ sizes, and our designs are tested according to EN and API standards. We can also provide ASME U-stamp pressure vessel certification for arrestor housings if required (useful for integrating into ASME coded systems). Furthermore, we furnish material test reports (Mill Test Certs) and other documentation for QA. If your project is being reviewed by authorities or third-party inspectors (TÜV, Lloyd’s Register, etc.), having these certifications will smooth approval. Always request the certificate of conformity and the performance test report of the flame arrestor – reputable manufacturers like Storagetech will gladly supply these. For example, our detonation arrestors come with a test report detailing that they were tested for both deflagration and detonation conditions as per ISO 16852, giving you confidence in their performance.

10. Integration with Other Equipment: Plan how the flame arrestor will integrate with your system. Often, flame arrestors work in tandem with other safety devices like pressure vacuum valves, breather vents, or emergency vents. Ensure the connection (flange rating, bolt pattern) matches your existing equipment. You might choose to use a combined unit (as discussed earlier) to simplify. Also consider if you need accessories like a flame guard weather hood, temperature sensors (some systems include thermal probes near flame arrestors to detect if it’s stopping a flame), or flow monitoring. Storagetech can custom-build flange adaptors or combination assemblies to make integration seamless. For instance, if you have a conservation vent and want to add a flame arrestor, we can likely provide a solution that bolts onto it or a replacement that incorporates both. Don’t forget to consider the placement: a flame arrestor should be as close as possible to the potential ignition source for maximum effectiveness (except when used for detonation arresters, where placement is dictated by code or specific scenarios).

By evaluating all the above factors, you can narrow down the exact flame arrestor model and specification that will best protect your operation. Safety is the priority, but cost, maintenance, and performance all play roles. Storagetech’s technical sales team often assists clients in this selection process – we’ll ask about your application details and can recommend the optimal solution. We pride ourselves not just on manufacturing flame arrestors, but also on being consultants in explosion safety. When you partner with Storagetech, you gain access to decades of expertise to ensure you get the right flame arrester for the job on the first try.

Storagetech™ Flame Arrestors – Features & Benefits

Storagetech is committed to delivering premium flame arrestors that meet and exceed industry standards. Our flame arrestor lineup is engineered with a blend of innovative design, high-quality materials, and rigorous testing to provide reliable protection in the harshest industrial environments. Here are some of the standout features and benefits of choosing Storagetech flame arrestors:

-

ATEX-Certified & Globally Compliant: All Storagetech flame arrestors are ATEX certified (up to 18″ diameter) for use in explosive atmospheres, and designed/tested according to international standards like EN ISO 16852 and relevant API/NFPA codes. We can provide ASME U-Stamp certification, PED compliance (Pressure Equipment Directive for Europe), and other approvals as needed. This means our products are ready for use worldwide, in any regulatory environment, giving you peace of mind about compliance and safety audits.

-

Robust Construction & Durable Materials: Storagetech flame arrestors are built to last. We use heavy-duty casings (carbon steel, ductile iron, or stainless steel as standard) and corrosion-resistant internals. The flame quenching elements are made from materials like stainless steel or special alloys that resist corrosion and thermal stress. For corrosive services, we offer materials like Hastelloy or Monel. Our arrestors are often finished with protective coatings (e.g., epoxy paint or PTFE) for extra longevity in marine or corrosive environments. This robust design ensures the arrestors maintain integrity even after years of service, in harsh sun, rain, salt air, or chemical exposure. Users report that Storagetech arrestors continue performing with minimal maintenance, reflecting our superior build quality.

-

High Performance (Low Pressure Drop): Thanks to advanced flame cell technology, Storagetech flame arrestors provide excellent flame-stopping capability with minimal impact on your process flow. Our unique element designs (such as reverse-wound crimped ribbon) create a long flame path that maximizes quenching while keeping pressure loss low. Tests have shown around 30% lower pressure drop compared to conventional flame arrestor designs at equivalent flow rates. For you, this means less energy loss, lower tank breathing resistance, and reduced risk of pressure-related process upsets. Even our detonation arrestors, which are by nature dense, are optimized to not choke your vent or vapor line under normal conditions. High flow capacity and quick response (quenching flames in milliseconds) characterize every Storagetech flame arrester.

-

Wide Range of Models for Different Needs: Storagetech produces a comprehensive range of flame arrestor models: end-of-line deflagration arrestors in various sizes (with or without pressure/vacuum valves), inline deflagration arrestors (vertical and horizontal), inline detonation arrestors (stable/unstable detonation proof), combination units, and special configurations. We have standardized models to cover most applications, but we also customize if your scenario demands it. Need a special connection type or an unusual size? We can design to spec. This extensive range ensures that you will find a Storagetech flame arrestor that fits your application like a glove – no need to jury-rig a solution. For instance, our standard lineup covers Explosion Groups IIA and IIB gases, and we can provide designs for IIC (e.g., hydrogen service) on request. By offering everything from small 2″ tank vent flame arrestors to gigantic 30″ pipeline arrestors, Storagetech truly is a one-stop supplier for flame arresters.

-

Maintenance-Friendly & Easy Assembly: We understand the importance of ease of maintenance in industrial equipment. Storagetech flame arrestors are engineered for convenient access. Many models feature flanged covers or quick-release clamps that allow you to inspect the flame cell element without removing the entire unit from the line. The internal elements are made in cartridge form in larger sizes, which can be pulled out, cleaned, or replaced swiftly. Our design minimizes loose parts – for example, the flame cell stays intact and doesn’t fall apart during disassembly, avoiding any reassembly errors. Moreover, the arrestors are designed such that reinstalling them is straightforward (no need for complicated alignment). As a result, your maintenance crew can service the units quickly, reducing downtime. As one of our product highlights, Storagetech flame arrestors are “easy to remove, maintain and assemble”, which translates to cost savings over the life of the product. We also provide clear maintenance manuals and support, including guidance on inspection intervals (which often depends on the severity of service – many customers find that annual inspections are sufficient due to our superior anti-fouling designs).

-

Customizable Solutions & Engineering Support: Industrial processes can be unique, and Storagetech prides itself on working closely with customers to tailor flame arrestor solutions. If your project has special requirements (be it a certain footprint, a combination of safety functions, or an uncommon fluid), our engineering team will collaborate to design a suitable arrestor. We have delivered custom flame arrestors for niche applications – e.g., high-pressure biogas systems, research labs handling reactive gases, and even aesthetics-oriented projects where the arrestor needed a certain finish. Our Quick Engineering and Sizing Tool (similar to what competitors like offer) can help rapidly size and select a flame arrester for your parameters. Additionally, we offer on-site or video consultation for complex installations. This level of support ensures you not only get a product, but a solution tuned to your needs.

-

Proven Track Record and Quality Assurance: With over 40 years in the industry, Storagetech (a brand of Äager GmbH) has flame arrestors protecting facilities worldwide. Our success stories include major oil refineries, global chemical plants, and large tank farms that have standardized on Storagetech flame arrestors for their reliability. Each flame arrestor we ship undergoes rigorous quality checks. We perform flow testing, flame quenching testing (per standards), and thorough inspections (welding, dimensional, material) under ISO 9001 QA systems. Third-party inspections by agencies like TÜV, Bureau Veritas (BV), and SGS can be arranged and are often done, so you can trust that what you receive meets the promised specifications. All units come with proper documentation and certificates. This focus on quality and our experience in global projects means Storagetech is a flame arrester partner you can trust for the long haul – our devices will do their job when called upon, protecting your people and assets.

In essence, Storagetech flame arrestors offer uncompromising safety performance combined with the practical features that industrial operators appreciate (easy maintenance, low pressure drop, flexibility). They are the result of decades of R&D, as well as continuous improvement by gathering feedback from field use. When you install Storagetech flame arrestors, you’re investing in reliability, compliance, and peace of mind.

Optimizing Your Safety System with Storagetech

Beyond flame arrestors, Storagetech provides a full suite of safety solutions for storage tanks and process systems – including Pressure Vacuum Valves (PVRVs), emergency relief vents, gauge hatches, and more. These devices often work hand-in-hand with flame arrestors. For example, a flame arrestor on a tank vent is frequently paired with a pressure/vacuum valve that regulates tank pressure. By sourcing these from Storagetech, you ensure compatibility and top-tier quality across the board. We encourage integrating flame arrestors into a broader safety strategy: think of them as one layer in a multi-layered protection approach (along with inert gas systems, gas detectors, and good operating practices).

Storagetech’s experience across industries means we can also advise on semantic or long-tail queries that you might encounter when specifying flame arrestors. Whether you’re looking for an “industrial flame arrester supplier” who can deliver on a tight timeline, or trying to find the best “inline flame arrester for chemical tank vapor lines”, our team is ready to assist with expert guidance. We stay on top of market trends and innovations – be it new materials that increase efficiency or design tweaks to address emerging standards (like the growing hydrogen economy which demands IIC arrestors). Our goal is not just to sell a product, but to ensure you get value in terms of safety enhancement and operational assurance.

Why Choose Storagetech Flame Arrestors?

Choosing Storagetech means choosing a partner dedicated to your safety and success. We strive to help our clients compete at the highest level of safety and compliance. When you compare Storagetech flame arrestors to those from the industry benchmarks – you’ll find that Storagetech stands shoulder-to-shoulder with them, and in some aspects even surpasses. Our prices are competitive, often providing a more cost-effective solution without compromising on quality, which is crucial for procurement decisions in B2B settings.

Our flame arrestors are the result of continuous innovation. For instance, while emphasizes their special technology and their E-Flow elements, Storagetech has developed its own proprietary element designs and coating techniques that achieve similar flame quenching performance. We also focus on user-friendly design, which might not always be the top priority of some legacy brands. The combination of certified safety and practical usability is a hallmark of Storagetech.

Furthermore, Storagetech’s manufacturing and design capability is agile – meaning we can often deliver custom configurations faster. In a recent project, when a client needed a unique inline flame arrester configuration on a tight deadline, Storagetech delivered ahead of schedule, something larger competitors could not commit to. This agility, along with our customer-centric approach, makes the difference. Our engineering team is accessible to customers for discussions, and our global support network means help is always nearby (through our distributors and service centers).

Lastly, Storagetech as part of the Äager group, invests heavily in R&D and quality. We operate state-of-the-art manufacturing facilities and flame testing labs to ensure every design is proven. We also provide training and resources – for example, articles like “Choosing the Right Flame Arrester” (available in our Case Studies & Articles) help educate the industry, and we host webinars for safety training. This thought leadership underlines our expertise and commitment.

When you sum it up, Storagetech flame arrestors offer unrivaled quality, unmatched expertise, and unparalleled service. We stand by our products and we stand by our customers. Protecting your facility from explosions is a serious responsibility – and Storagetech is the name you can trust to carry that responsibility with you.

Conclusion & Call to Action

Flame arrestors are a critical component of any industrial safety and explosion protection strategy. On this page, we’ve provided a comprehensive overview of flame arrestors – what they are, how they work, the different types, industry applications, and guidelines for selecting the right one. By now, you should have a clear understanding that installing quality flame arrestors is not just a regulatory checkbox, but a prudent measure to protect your people, plant, and profits. Whether you operate an oil refinery, manage a chemical plant, run a fuel storage depot, or oversee safety for a marine terminal, flame arrestors can be the difference between a minor incident and a major disaster.

Storagetech™ invites you to leverage our four decades of expertise in this field. As a global flame arrestor manufacturer and supplier, we have helped countless clients achieve safer operations. Our flame arrestors are engineered to guard against the worst-case scenarios so you can focus on running your business with confidence. We combine technical excellence with a customer-focused approach – delivering not just products, but solutions tailored to your needs and support whenever you need it.

If you are in the market for flame arrestors or reviewing your facility’s explosion safety measures, we encourage you to reach out to Storagetech for a consultation or quote. Our team will help identify the ideal flame arrester model (or models) for your specific use case, be it an inline flame arrester for a chemical tank farm or a deflagration arrestor for a pharmaceutical vent system. We’ll also ensure you consider complementary equipment like flame arrestor-integrated pressure vacuum relief valves for a holistic solution.

Secure your operations and stay compliant with the industry’s evolving safety standards – equip your facility with Storagetech flame arrestors. Contact us today to discuss your requirements, get technical details, or request pricing. Our experts are ready to assist and provide you with a competitive quote and any technical documentation you may require.

Investing in Storagetech flame arrestors is an investment in safety, reliability, and peace of mind. Join the ranks of our satisfied customers worldwide who trust Storagetech to keep their operations safe from fires and explosions.